Austinjs0102

Active Member

Hey Everyone.

Im fairly new to homebrewing. I started back in 2015 but have been off and on with it due to moving, getting engaged and overall space and time. Now as things are settling down, i am looking to get back into it.

My dilemma right now is 3 Vessel vs a EBIAB.

If i went 3 vessel it would be a 15 gallon set up, electric as i would like to brew inside. I have a basement room with a drain location, water faucet and the ability to run the electrical for a reasonable amount.

I do not plan on doing anything larger than 5 Gallon for some time. I also do not have a budget of 5k to spend.

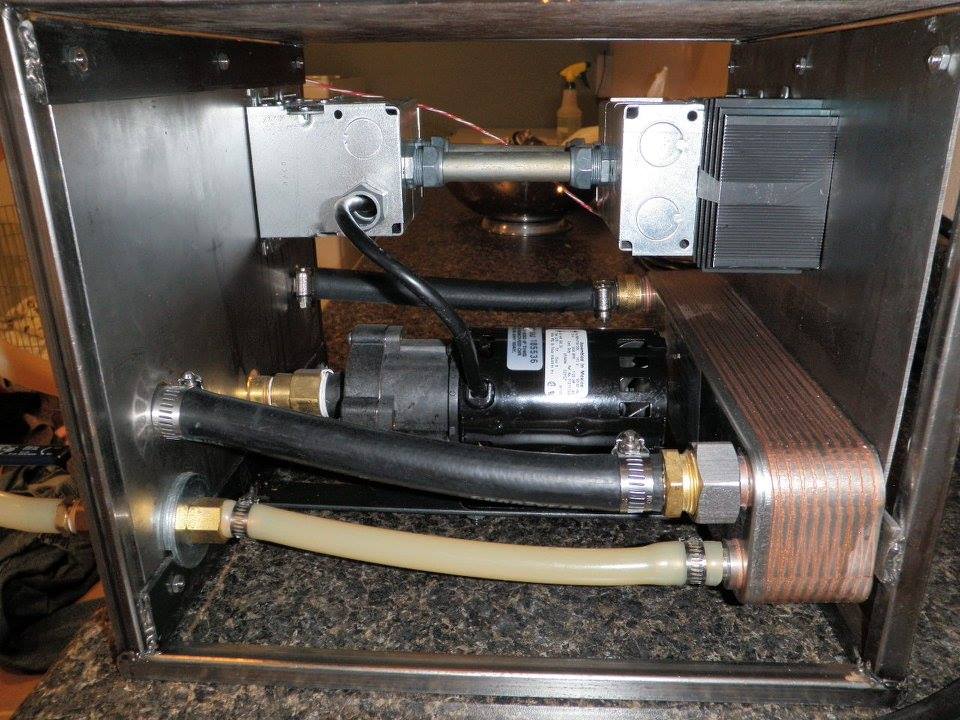

So this is why i leaning to a 10 to 15 Gallon eBIAB set up. I can use a 30amp breaker, 5500w element and it will use a lot let space as well as cost. I have the ability for a pulley system but squeezing the bag is a bit of a concern.

Some of my questions and thoughts are:

1. Should i sparge if i go EBIAB? Will it get better efficiency?

2. Will a 10 gallon pot be enough for doing 5G BIAB or should i look at a 15G pot.

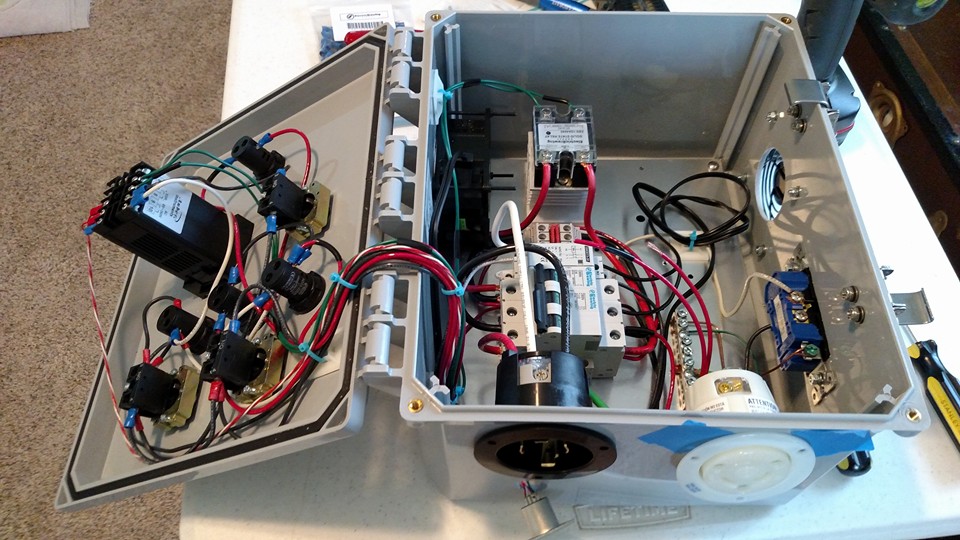

3. Ebrewery has a panel for $575 which seems reasonable. Do any of you who do eBIAB have a cost break down for your panel?

4. Overall, i just want to know your successes with BIAB as i really want to get into more brewing but i just cannot pull the trigger without some good advice.

Currently my set up was a 15G Kettle with propane and a Cooler mash tun. It worked but i want to be able to brew in the winter and when temps hit -40F, its not an option to brew outside.

Also, If moving to eBIAB with a pump set up, how many ports should i be looking at on the kettle or overall what would be the best configuration.

Thanks again

Im fairly new to homebrewing. I started back in 2015 but have been off and on with it due to moving, getting engaged and overall space and time. Now as things are settling down, i am looking to get back into it.

My dilemma right now is 3 Vessel vs a EBIAB.

If i went 3 vessel it would be a 15 gallon set up, electric as i would like to brew inside. I have a basement room with a drain location, water faucet and the ability to run the electrical for a reasonable amount.

I do not plan on doing anything larger than 5 Gallon for some time. I also do not have a budget of 5k to spend.

So this is why i leaning to a 10 to 15 Gallon eBIAB set up. I can use a 30amp breaker, 5500w element and it will use a lot let space as well as cost. I have the ability for a pulley system but squeezing the bag is a bit of a concern.

Some of my questions and thoughts are:

1. Should i sparge if i go EBIAB? Will it get better efficiency?

2. Will a 10 gallon pot be enough for doing 5G BIAB or should i look at a 15G pot.

3. Ebrewery has a panel for $575 which seems reasonable. Do any of you who do eBIAB have a cost break down for your panel?

4. Overall, i just want to know your successes with BIAB as i really want to get into more brewing but i just cannot pull the trigger without some good advice.

Currently my set up was a 15G Kettle with propane and a Cooler mash tun. It worked but i want to be able to brew in the winter and when temps hit -40F, its not an option to brew outside.

Also, If moving to eBIAB with a pump set up, how many ports should i be looking at on the kettle or overall what would be the best configuration.

Thanks again

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)