...If space, skills and/or cash is limited, there is nothing "wrong" with a BIAB setup...

Regarding space, I have a 60'x80' shop building where I brew, so space is not an issue. Regarding skills, I'm an industrial/mechanical designer well versed in designing/fabricating in most any material. Regarding cash, I'm not rich but I have the money to buy any type of system.

I thoroughly researched all the options and very consciously chose to go with simple single vessel BIAB rig. I have yet to find a reason to regret that decision.

You are correct that there is nothing wrong with BIAB. But your comments make it clear that you have the mistaken belief (as do many brewers) that other systems are somehow inherently "better", or that they would be an "upgrade" from BIAB. That belief is far from true. I would consider unnecessary complexity to be a downgrade from my elegantly simple and effective BIAB rig.

...drawbacks for me that come to mind are (1) efficiency (2) repeatability when scaling up or down and (3) lifting the bag out....

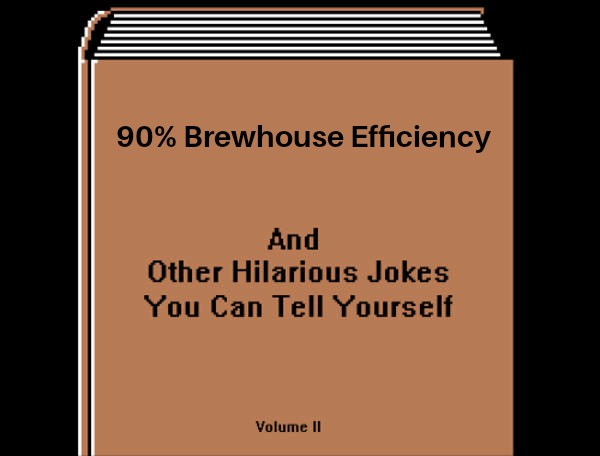

I don't sparge, squeeze, or recirculate and I get low to mid 80's efficiency. If I want more alcohol content I always have the option of sparging, but since I can hit or exceed recipe targets without a sparge I normally just don't bother with it.

I don't buy the claim that repeatability and scalability is a drawback of BIAB. My repeatability is very good. On my last brew my mash temp stayed within 1 degree of target for a full 60 minute mash, using only an old sleeping bag to insulate the kettle. I'm not guessing about the temp, I use a Thermoworks remote probe thermometer so I can see the temp within the kettle without removing the insulation.

Lifting the bag is not an issue. Maybe it is if you are trying to do a stovetop 10gal batch, alone, without an overhead lift point -- but the problem there is poor planning, not the BIAB process.

I have an overhead lift point for hoisting the bag, which I use with a simple ratcheting pulley setup that gives me a 2:1 mechanical advantage. I can easily lift the bag with one hand. The ratcheting pulley removes the risk of it falling back into the kettle.

I let gravity drain the bag over the kettle during the boil. After it's drained it is light and easy to handle. I grab the top of the bag, the part that is not wet and sticky, release the ratchet pulley, and drop the bag into a bucket for disposal.

My brew days are hassle free and enjoyable. My total brew time averages about 3:45. That includes everything, from beginning to fill the kettle to everything cleaned and put away. That includes no prior preparation, everything is done on brew day, and I do a full hour mash and a full hour boil.

The brewing is fun. The beer tastes great. The chances of me having a stuck sparge, controller problem, pump issue, etc, is zero. I have no desire to downgrade to a more complicated system.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I enjoy seeing what they come up with (as I think you do) If I were doing larger batches than 4 or 5 gallons, I would probably go to some kind of 3V system because I don't have the hoists and stuff to deal with large heavy grain bags. But I can handle 10 pounds of grain just fine with what I have, and there's a lot you can do with 8 to 10 pounds of grain.

I enjoy seeing what they come up with (as I think you do) If I were doing larger batches than 4 or 5 gallons, I would probably go to some kind of 3V system because I don't have the hoists and stuff to deal with large heavy grain bags. But I can handle 10 pounds of grain just fine with what I have, and there's a lot you can do with 8 to 10 pounds of grain.