I agree. Another way to negate the concern is to solder the inside coupling to the washer. In that way, the seal is made between the washer and cooler wall. A little teflon tape on the threads and you're good to go.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The No-Leak MLT bulkhead design

- Thread starter Bobby_M

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

JKoravos

Well-Known Member

I agree. Another way to negate the concern is to solder the inside coupling to the washer. In that way, the seal is made between the washer and cooler wall. A little teflon tape on the threads and you're good to go.

Good idea. I like that.

Hi there -

I'm probably going to build my MLT this week, and I'm really liking this method, since, as you note, it does seem to avoid some of the basic problems with cooler bulkhead designs. I'm really trying to get everything straight in my head before I build it, so I have a few questions - many apologies if they're kind of basic or newb-y:

1) When you guys are talking about using Bondo or something of that sort between the cooler walls, this would be a substitute for the PVC, right, not in addition to it? i.e. that would firm up the cooler walls even better than the PVC would? My cooler doesn't have a spigot, so I have to drill a hole anyway, so I'm thinking that I might just drill a 7/8" hole, dig out some of the insulation around it, fill the area with Bondo, and install the rest as directed, without needing to drill the outside to 1-1/8".

2) With this design I'm assuming you attach the braid to the hose barb the same way you do with Flyguy's method? i.e. you'd use stainless hose clamps or zip-ties or whatever works for you. Do you recommend putting tubing (with holes cut in it) inside the braid, a la Flyguy, or would you just do without it?

3) Just to be clear, the reason you're not just sealing the nipple to the inside cooler wall with food-grade silicon (which should prevent all leaks) is that you want this bulkhead build to be removable? If one doesn't care about that (i.e. if I'm really only planning on building one MLT for the time being), then would there be any reason why I wouldn't just go ahead and seal it in?

Thanks in advance, and again, apologies if these are basic questions.

I'm probably going to build my MLT this week, and I'm really liking this method, since, as you note, it does seem to avoid some of the basic problems with cooler bulkhead designs. I'm really trying to get everything straight in my head before I build it, so I have a few questions - many apologies if they're kind of basic or newb-y:

1) When you guys are talking about using Bondo or something of that sort between the cooler walls, this would be a substitute for the PVC, right, not in addition to it? i.e. that would firm up the cooler walls even better than the PVC would? My cooler doesn't have a spigot, so I have to drill a hole anyway, so I'm thinking that I might just drill a 7/8" hole, dig out some of the insulation around it, fill the area with Bondo, and install the rest as directed, without needing to drill the outside to 1-1/8".

2) With this design I'm assuming you attach the braid to the hose barb the same way you do with Flyguy's method? i.e. you'd use stainless hose clamps or zip-ties or whatever works for you. Do you recommend putting tubing (with holes cut in it) inside the braid, a la Flyguy, or would you just do without it?

3) Just to be clear, the reason you're not just sealing the nipple to the inside cooler wall with food-grade silicon (which should prevent all leaks) is that you want this bulkhead build to be removable? If one doesn't care about that (i.e. if I'm really only planning on building one MLT for the time being), then would there be any reason why I wouldn't just go ahead and seal it in?

Thanks in advance, and again, apologies if these are basic questions.

1. Right, the PVC was one way to firm up the wall to wall gap. Bondo, etc, would do the same thing.

2. You shouldn't have a problem with a plain braid, but I've found the larger diameter ones meant for water heater connections is a little more hefty.

3. I'm not sold on silicone's ability to stick to the HDPE liner of the cooler long term. As recently mentioned, I like the idea of a silicone washer more than an Oring.

2. You shouldn't have a problem with a plain braid, but I've found the larger diameter ones meant for water heater connections is a little more hefty.

3. I'm not sold on silicone's ability to stick to the HDPE liner of the cooler long term. As recently mentioned, I like the idea of a silicone washer more than an Oring.

Derek

Member

Initially I considered just filling the space, but I think using the spacer (with or without filler) is actually a better idea.

The two walls typically aren't parallel (the inner one typically slopes in). The inner wall on the xtreme cooler had a lot of curvature around the factory spigot as well. With a spacer, everything should compress down making the walls perpendicular to the nipple & providing a nice flat surface for the washer to seal.

I guess you could open it up; fill it; and compress it down (to some extent) to get everything lined up as it hardens...

The two walls typically aren't parallel (the inner one typically slopes in). The inner wall on the xtreme cooler had a lot of curvature around the factory spigot as well. With a spacer, everything should compress down making the walls perpendicular to the nipple & providing a nice flat surface for the washer to seal.

I guess you could open it up; fill it; and compress it down (to some extent) to get everything lined up as it hardens...

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

JKoravos

Well-Known Member

3. I'm not sold on silicone's ability to stick to the HDPE liner of the cooler long term. As recently mentioned, I like the idea of a silicone washer more than an Oring.

At least for Igloo coolers, the interior liner is polypropylene. From an adhesive bonding perspective, HDPE and PP are essentially the same, they're both very low surface energy plastics. It's extremely hard to get anything to permanently bond to them.

BargainFittings

Vendor / Owner

At least for Igloo coolers, the interior liner is polypropylene. From an adhesive bonding perspective, HDPE and PP are essentially the same, they're both very low surface energy plastics. It's extremely hard to get anything to permanently bond to them.

Aquamend epoxy will bond to it. Its the only retail product I found that would.

MrNate

Well-Known Member

apparently I didn't read the previous 3 responses. nevermind.

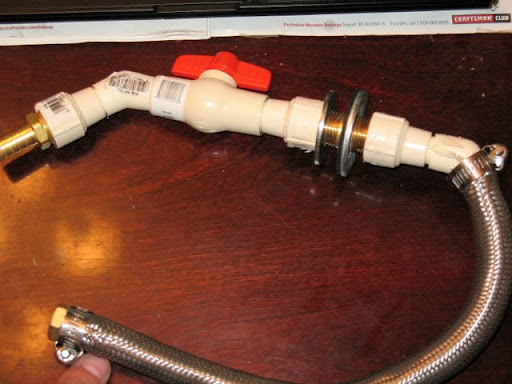

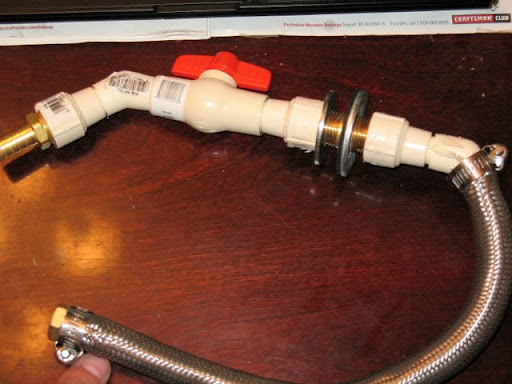

(edit - save some time, I added pics a few posts later)

Hey,

I don't have any pics, but I'll get some taken and post them. Here is how I put mine together for 10 gal Powerade cooler ('cause blue is better), and it hasn't leaked.....

I used a similar design as the OP, but instead of 1 and 10, I used two 1/2" cpvc female adapter which threads right onto the brass nipple.

I took two stainless washers for the inside dremel-ed the hole out so that they would fit snug on the smooth portion of the nipple, and bent (I guess curved) them so that they matched the profile of the cooler. I also found some large rubber washer that fit really snug over the smooth surface and trimmed it to the same size as the stainless washers.

On the outside, I used some washer and the original bushing for the spigot as spacer for the other female adapter to push against before bottoming out in its threads.

I put it together by placing the rubber washer on the smooth part and then the curved wahers so that the first washer is just to the threads. The second washer is there so that the female adapter on the inside hits it before the threads bottom out. Place it through the hole and assemble the outside portion, tightening the outside while holding the curved washers in place on the inside.

I finish the inside off with a small piece of 1/2" cpvc, then a 22* angle, and another small piece of 1/2" cpvc and a water heater stainless braid "finger-locked" onto the 1/2" piece sticking out and clamped with a stainless hose clamp. The 22* fitting serves to get the braid on the bottom and lower the standing water volume left behind to a mere 1/4" or so.

On the outside I used 1/2" cpvc to a 1/2" cpvc ball valve, then a 45*, then some sorta cpvc fitting with female threads and a male brass nipple and braided vinyl tubing attached to it. (I don't remember what I used exactly)

(edit - clicked post not preview) The only thing I am going to do different is cement portions together, as it tends to get a little loose when it all heats up - and things (the ball valve mostly) start to shift when you use it hot and not cemented.

Hey,

I don't have any pics, but I'll get some taken and post them. Here is how I put mine together for 10 gal Powerade cooler ('cause blue is better), and it hasn't leaked.....

I used a similar design as the OP, but instead of 1 and 10, I used two 1/2" cpvc female adapter which threads right onto the brass nipple.

I took two stainless washers for the inside dremel-ed the hole out so that they would fit snug on the smooth portion of the nipple, and bent (I guess curved) them so that they matched the profile of the cooler. I also found some large rubber washer that fit really snug over the smooth surface and trimmed it to the same size as the stainless washers.

On the outside, I used some washer and the original bushing for the spigot as spacer for the other female adapter to push against before bottoming out in its threads.

I put it together by placing the rubber washer on the smooth part and then the curved wahers so that the first washer is just to the threads. The second washer is there so that the female adapter on the inside hits it before the threads bottom out. Place it through the hole and assemble the outside portion, tightening the outside while holding the curved washers in place on the inside.

I finish the inside off with a small piece of 1/2" cpvc, then a 22* angle, and another small piece of 1/2" cpvc and a water heater stainless braid "finger-locked" onto the 1/2" piece sticking out and clamped with a stainless hose clamp. The 22* fitting serves to get the braid on the bottom and lower the standing water volume left behind to a mere 1/4" or so.

On the outside I used 1/2" cpvc to a 1/2" cpvc ball valve, then a 45*, then some sorta cpvc fitting with female threads and a male brass nipple and braided vinyl tubing attached to it. (I don't remember what I used exactly)

(edit - clicked post not preview) The only thing I am going to do different is cement portions together, as it tends to get a little loose when it all heats up - and things (the ball valve mostly) start to shift when you use it hot and not cemented.

Pretty slick. I didn't even know about those fittings.

As another question, does anyone know of why I wouldn't be able to just use a true bulkhead made from ABS plastic?

They have good ratings for most acids up to 50% and 24hr. Temp rated for -40°F to 180°F....the only thing they have a poor rating for is alcohols and some agents that people might use (chlorine and iodine), but the wort would be just sugar at the time of contact and I don't use those chemicals, or diesel or gasoline in my process (Chemical Resistance Data | LATI S.p.A.)

I have these laying around from all my fish stuff, just haven't seen anyone use or mention them.....or mention why not to use them.

Thanks, MT

They have good ratings for most acids up to 50% and 24hr. Temp rated for -40°F to 180°F....the only thing they have a poor rating for is alcohols and some agents that people might use (chlorine and iodine), but the wort would be just sugar at the time of contact and I don't use those chemicals, or diesel or gasoline in my process (Chemical Resistance Data | LATI S.p.A.)

I have these laying around from all my fish stuff, just haven't seen anyone use or mention them.....or mention why not to use them.

Thanks, MT

Pretty slick. I didn't even know about those fittings.

Found them under the cpvc sticks over a sLowes'.....they got all sorts. So far it has worked pretty good. And it's lightweight so there isn't much pressure on the walls.

Later, MT

Do those bulkheads have inside threads? The hole you'd have to drill in the cooler wall is pretty big but otherwise it's a good idea. You'd have to reduce the outside threads down to mate it to the ball valve unless it has inside threads from both sides.

Do those bulkheads have inside threads? The hole you'd have to drill in the cooler wall is pretty big but otherwise it's a good idea. You'd have to reduce the outside threads down to mate it to the ball valve unless it has inside threads from both sides.

I was going to use the bulkheads that are made to slip pvc into each side. Cpvc isn't the same diameters, but I bet it's close enough for this application. I was just wondering if anyone knows of any chemical leaching issues.....I can't find any ideas.

Thanks, MT

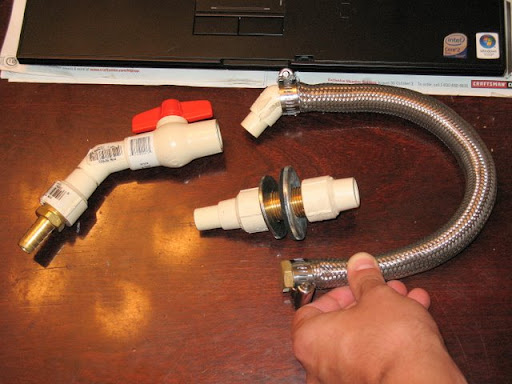

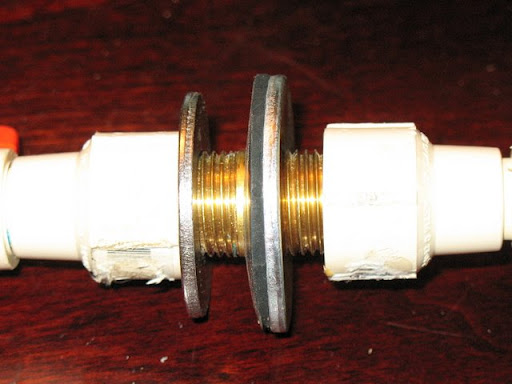

Ok, here's how I set mine up. I also noticed when I just took it aprt, that my hole is just through two layers of plastic (inside and outside). It looks like the manufacturing process for these powerade coolers sorta welds the two parts together at this point and they just punch a hole through that for the spigot.

Anyway, I was a little inaccurate on my previous post on a few details...Everything is still 1/2" cpvc, but the angles are 45's and I only used one washer on the inside and outside. I had to dremel out the hole in both washers to get it to fit easily (they must have been 3/8"), and I bent the inside washer to fit the curve of the cooler.

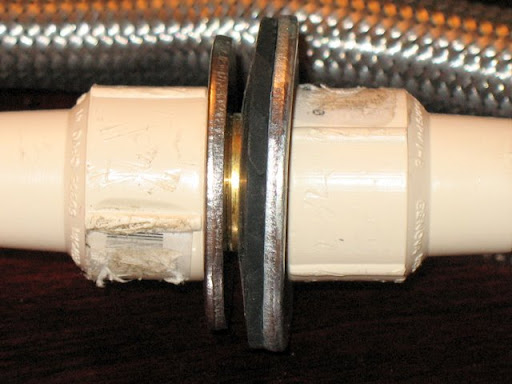

Here's what it looks like put together (loosely)

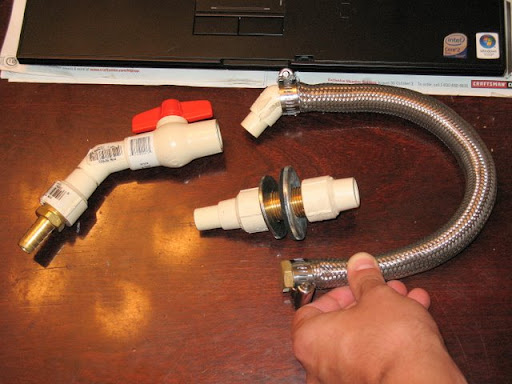

Here's a shot of it taken apart.

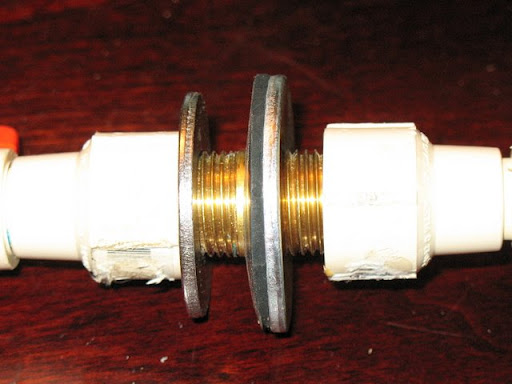

Here's a close up of the brass nipple...notice the curve on the right washer?

The black rubber washer sits about in the middle of the smooth part of the nipple, and the stainless washer (right), is about all the way on the smooth part.

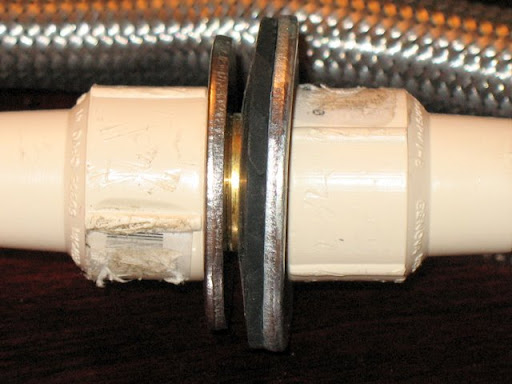

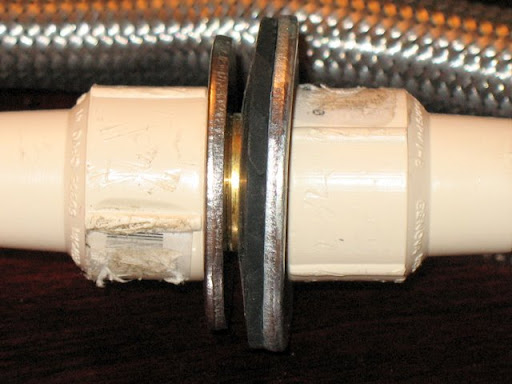

Here it is tightened down

My cooler wall is maybe twice as thick as the space left over, so everything cinches down nice and snug. This configuration works well for my cooler, but I don't have to deal with the walls collapsing any. You could used the OP configuration and just sub the cpvc in for the metal part. This might save some wear and tear on the plastic cooler walls, as the whole thing only weighs just shy of 273g (~10 oz.)

I think I am going to try the 1/2" ABS bulkhead if it's not to destructive, and if I can find some around here. Of course, I see 'em all time...but when I want one, I can only find 3/4"!!!

Thanks, MT

Anyway, I was a little inaccurate on my previous post on a few details...Everything is still 1/2" cpvc, but the angles are 45's and I only used one washer on the inside and outside. I had to dremel out the hole in both washers to get it to fit easily (they must have been 3/8"), and I bent the inside washer to fit the curve of the cooler.

Here's what it looks like put together (loosely)

Here's a shot of it taken apart.

Here's a close up of the brass nipple...notice the curve on the right washer?

The black rubber washer sits about in the middle of the smooth part of the nipple, and the stainless washer (right), is about all the way on the smooth part.

Here it is tightened down

My cooler wall is maybe twice as thick as the space left over, so everything cinches down nice and snug. This configuration works well for my cooler, but I don't have to deal with the walls collapsing any. You could used the OP configuration and just sub the cpvc in for the metal part. This might save some wear and tear on the plastic cooler walls, as the whole thing only weighs just shy of 273g (~10 oz.)

I think I am going to try the 1/2" ABS bulkhead if it's not to destructive, and if I can find some around here. Of course, I see 'em all time...but when I want one, I can only find 3/4"!!!

Thanks, MT

paledragon

Well-Known Member

just to throw my design into the mix, in case anyone wants to try it.

https://www.homebrewtalk.com/f11/yet-another-bulkhead-design-pics-126782/

https://www.homebrewtalk.com/f11/yet-another-bulkhead-design-pics-126782/

I cemented mine into three parts now, not six or more...and it is a lot easier to put together now that I have more to grab and twist on the outside!

I also measured the waste on mine so I can start accounting for it. When left flat, right at 2qt and fairly slow draining. When dipped it's just over 2qt, but much much faster draining. I think I'll just let it sit flat.

I also measured the waste on mine so I can start accounting for it. When left flat, right at 2qt and fairly slow draining. When dipped it's just over 2qt, but much much faster draining. I think I'll just let it sit flat.

Ok, so I've spent the last week putting this thing together. Just tested it out tonight and ... it leaks. A fair amount (i.e. a slow but steady dribble). Anyone have any suggestions?

Here's what I did: my cooler didn't have a drain, so I drilled out a 7/8" hole. I dug about 1.5" of insulation out around the hole, and replaced it with Bondo. I forgot how stinky that stuff is! But that gets rid of the "weak inner cooler wall" problem people have.

I then put the bulkhead together, pretty much as per Bobby's initial instructions. Since there was Bondo on the inside wall, I even tried to squeeze some silicone in behind the o-ring, just inside the cooler, and put some more between the inside washer closest to the inner wall and the wall itself (basically on the same vertical layer the o-ring is on, according to the diagram at the beginning of the thread.

The one difference (and this may be the problem, though I'm not sure) is that on the inside, I didn't want to put 7-8 washers between the hose barb and the o-ring/inner wall. That's probably about how many I'd need, and I figured it'd be better if I could just put some sort of lock nut in there to squeeze the washers/o-ring against the inner wall. I had trouble finding a stainless or brass locknut, so I basically cut off the top of a plastic electrical conduit nut (or maybe it's a reducer? I'm not sure what it's called) and used that as a lock nut. It might not have been able to squeeze the washers as tightly as a real lock not would, so that may be my problem. Anyway, from inside to outside, here's basically what I have over the nipple:

female hose barb - plastic lock nut thing - 2 SS washers - O-ring (definitely over the non-threaded part of the nipple) - inner cooler wall - Bondo - outer cooler wall - 3 washers - electrical conduit nut - ball valve - male hose barb

If it's that inner lock-nut issue, anyone have luck getting ahold of a SS or brass locknut? I've been to 3 hardware places around here, and nobody's had anything like that. As I said, that may be the problem, since I may not be squeezing the O-ring enough. But does anyone else have any other ideas? Apologies for the long post ... I'm a little frustrated, since I was hoping to do my first AG this weekend. Maybe it's better to look at it as my last PM?

Maybe it's better to look at it as my last PM?

Thanks in advance for any help.

Here's what I did: my cooler didn't have a drain, so I drilled out a 7/8" hole. I dug about 1.5" of insulation out around the hole, and replaced it with Bondo. I forgot how stinky that stuff is! But that gets rid of the "weak inner cooler wall" problem people have.

I then put the bulkhead together, pretty much as per Bobby's initial instructions. Since there was Bondo on the inside wall, I even tried to squeeze some silicone in behind the o-ring, just inside the cooler, and put some more between the inside washer closest to the inner wall and the wall itself (basically on the same vertical layer the o-ring is on, according to the diagram at the beginning of the thread.

The one difference (and this may be the problem, though I'm not sure) is that on the inside, I didn't want to put 7-8 washers between the hose barb and the o-ring/inner wall. That's probably about how many I'd need, and I figured it'd be better if I could just put some sort of lock nut in there to squeeze the washers/o-ring against the inner wall. I had trouble finding a stainless or brass locknut, so I basically cut off the top of a plastic electrical conduit nut (or maybe it's a reducer? I'm not sure what it's called) and used that as a lock nut. It might not have been able to squeeze the washers as tightly as a real lock not would, so that may be my problem. Anyway, from inside to outside, here's basically what I have over the nipple:

female hose barb - plastic lock nut thing - 2 SS washers - O-ring (definitely over the non-threaded part of the nipple) - inner cooler wall - Bondo - outer cooler wall - 3 washers - electrical conduit nut - ball valve - male hose barb

If it's that inner lock-nut issue, anyone have luck getting ahold of a SS or brass locknut? I've been to 3 hardware places around here, and nobody's had anything like that. As I said, that may be the problem, since I may not be squeezing the O-ring enough. But does anyone else have any other ideas? Apologies for the long post ... I'm a little frustrated, since I was hoping to do my first AG this weekend.

Thanks in advance for any help.

The only thing I can figure is that your Oring isn't small enough diameter to apply sealing pressure against the nipple? You can fix that by putting teflon tape on the threads where the locknut ends up. That will stop liquid from getting through and the oring will just have to seal between the locknut face and cooler wall.

Ok, I'll try a smaller, super-tight O-ring. And put more teflon tape on the nipple. Good ideas.

And I guess I might as well look harder for a brass or SS locknut to hold the SS washers against the O-ring. Maybe that'll help me get a tighter fit? As is, the ball valve does spin around pretty easily, which makes me think there just may not be enough pressure on it.

Just to make sure, when you say

Thanks as always for your help. You da man!:rockin:

And I guess I might as well look harder for a brass or SS locknut to hold the SS washers against the O-ring. Maybe that'll help me get a tighter fit? As is, the ball valve does spin around pretty easily, which makes me think there just may not be enough pressure on it.

Just to make sure, when you say

you're including the SS washers in that space between the locknut and cooler wall, right? It seems like water could also drip in behind the o-ring where it's pressed against the cooler (space #3 in your diagram), especially if it's not squeezed tightly enough against the wall.That will stop liquid from getting through and the oring will just have to seal between the locknut face and cooler wall.

Thanks as always for your help. You da man!:rockin:

It definitely should be tight enough that the valve won't spin.

I'm currently putting some valves/bulkheads together too, having a real tough time finding 1/2" NPT nuts. Does the big orange store hide them somewhere less obvious than the plumbing section? My alternative is to just use more washers and use the valve body and female sleeve on the inside to load everything up. Not ideal, but I'm sure I can make it work.

No, you'll have to go online for NPT locknuts. Mcmaster.com Grainger.com MSCdirect.com

Ok, I finally got around to putting this together again. So yesterday I assembled everything, screwed it in super tightly, and ... filled it with hot tap water, left it for 2 hours, and it didn't leak a drop! Haven't put the inner hose barb and braid on yet, but now that I know it doesn't leak, I'm stoked.

The key was really using locknuts on both the inside and outside (brass on the inside, whatever on the outside - they're cheap at McMaster Carr). Locknuts are the only thing I found that could screw all the way up the threaded portion of the nipple, so you can really put as much pressure as possible on the washers / o-ring. I tried to use an electrical conduit nut on the outside, but even that only screws about halfway up the threads, so unless you use a lot of washers, it isn't as effective.

Thanks Bobby - seriously, your posts, your videos, your website, and your willingness to give advice to people at all levels of the process are a huge asset to the community. You rock!

The key was really using locknuts on both the inside and outside (brass on the inside, whatever on the outside - they're cheap at McMaster Carr). Locknuts are the only thing I found that could screw all the way up the threaded portion of the nipple, so you can really put as much pressure as possible on the washers / o-ring. I tried to use an electrical conduit nut on the outside, but even that only screws about halfway up the threads, so unless you use a lot of washers, it isn't as effective.

Thanks Bobby - seriously, your posts, your videos, your website, and your willingness to give advice to people at all levels of the process are a huge asset to the community. You rock!

Locknuts are the only thing I found that could screw all the way up the threaded portion of the nipple...

That's not entirely true, the female cpvc adapters get damn near all the way, and with one washer on each side, I get a good seal.

Of course, this may also depend on the thickness of the wall you are putting this thing through...which would also increase the length of the nipple. But, the length of the threads should be about the same, with just the smooth section being longer (I think),

Any way, glad you got a non-leaking set-up....I know how frustrating leaks are; I can't get my shower to stop, and new seats and stems only last a few weeks before dripping again!!!!

Later,

Hmmm, interesting. I must admit, I didn't check out your setup too much because I was so committed to getting the original idea to work. But it looks great! CPVC was one of the things I tried to find to use instead of a locknut (cause I didn't want to go through the hassle or expense of ordering one on-line; in retrospect, I would have saved tons of time and money if I had just done that first!). But I couldn't find a female adaptor that screwed more than halfway up the threads. Guess I just didn't look hard enough. :cross: Right on for finding your own way to solve the problem!

You could probably put the assembly in the oven for a few minutes and get it to thread on even further as the CPVC heats up.

Just want to report that I've done 2 AG brews with this setup now, and it hasn't even come close to leaking. This bulkhead is super water-tight. So kudos on the design!

Of course, it turns out that the guy at the local hardware store who swore up and down that the washers he was selling me were stainless steel was totally full of it, since the washers inside the cooler are already starting to get a layer of rust. So now I have to go back on the search for SS washers, drill them out again and take most of the assembly apart to replace the rusty ones. Awesome.

Still, excellent design.

Of course, it turns out that the guy at the local hardware store who swore up and down that the washers he was selling me were stainless steel was totally full of it, since the washers inside the cooler are already starting to get a layer of rust. So now I have to go back on the search for SS washers, drill them out again and take most of the assembly apart to replace the rusty ones. Awesome.

Still, excellent design.

TheCookieMonster

Well-Known Member

You could probably put the assembly in the oven for a few minutes and get it to thread on even further as the CPVC heats up.

I noticed on your video with the sight glass that you said you weren't a fan of weldless installations.

Did something happen with this since you put it in?

Thanks!

Similar threads

- Replies

- 7

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: Hoochin'Fool

-