Yup I'm building a stainless conical fermenter from a keg. No special tools needed, I'm farming out the welding but we will get to that. First calculate the cone, I like to worked out the math so the arc was exactly 180 degrees and let the cone angle fall where it may. I cut it out with one of my favorite tools, a 4-1/2 inch angle grinder. The small radius was very tricky to cut and not perfect, but it must be cut out or you can't bend the cone.

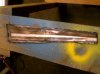

So the internet would tell you that you need a slip roller to roll sheet metal and even with one, a cone is difficult, but lets make our own. Take two pieces or round bar or tubing, I used 1/2 inch because thats what I had, but 1.5 or 2 would probably be better. Grind a two small flats on each end of each bar 180 degrees apart. Now place on the bench a washer, one bar, another washer, the other bar and clamp. The thickness of the middle washer should give you a gap between the bars slightly larger than thickness of the material.

Next draw a bunch of radial lines on the cone (you want them facing up) and gradually work the sheet metal into a cone.

So the internet would tell you that you need a slip roller to roll sheet metal and even with one, a cone is difficult, but lets make our own. Take two pieces or round bar or tubing, I used 1/2 inch because thats what I had, but 1.5 or 2 would probably be better. Grind a two small flats on each end of each bar 180 degrees apart. Now place on the bench a washer, one bar, another washer, the other bar and clamp. The thickness of the middle washer should give you a gap between the bars slightly larger than thickness of the material.

Next draw a bunch of radial lines on the cone (you want them facing up) and gradually work the sheet metal into a cone.