OK, I have my heating elements for my HLT and Brew Pot installed in my electric brew system.

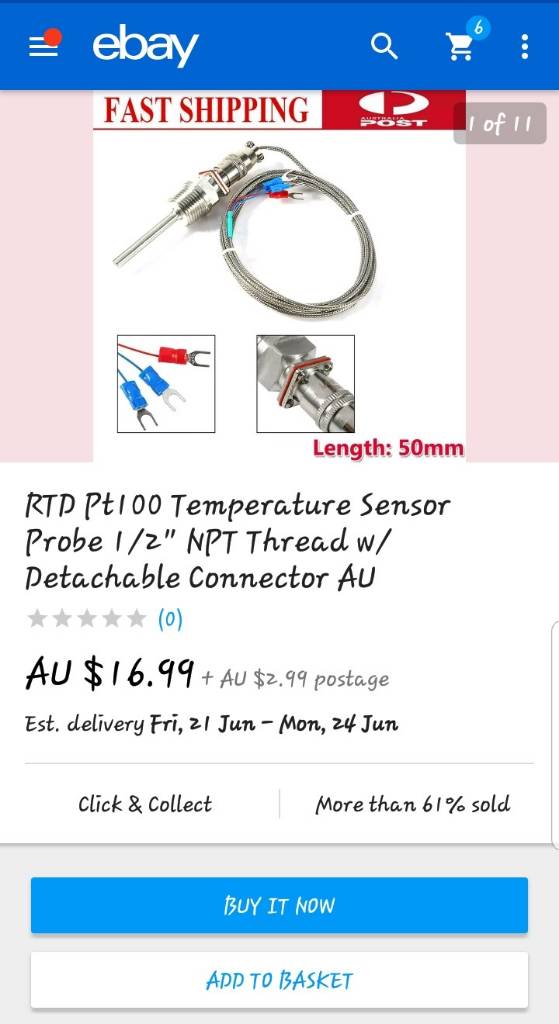

I have seen a few ways to install the Temperature probes. Some are right in the pot others are in a NPT tee fitting inline with the ball valve.

I am looking for what you guys, that have built your systems, have done and what you feel works better.

I have seen a few ways to install the Temperature probes. Some are right in the pot others are in a NPT tee fitting inline with the ball valve.

I am looking for what you guys, that have built your systems, have done and what you feel works better.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)