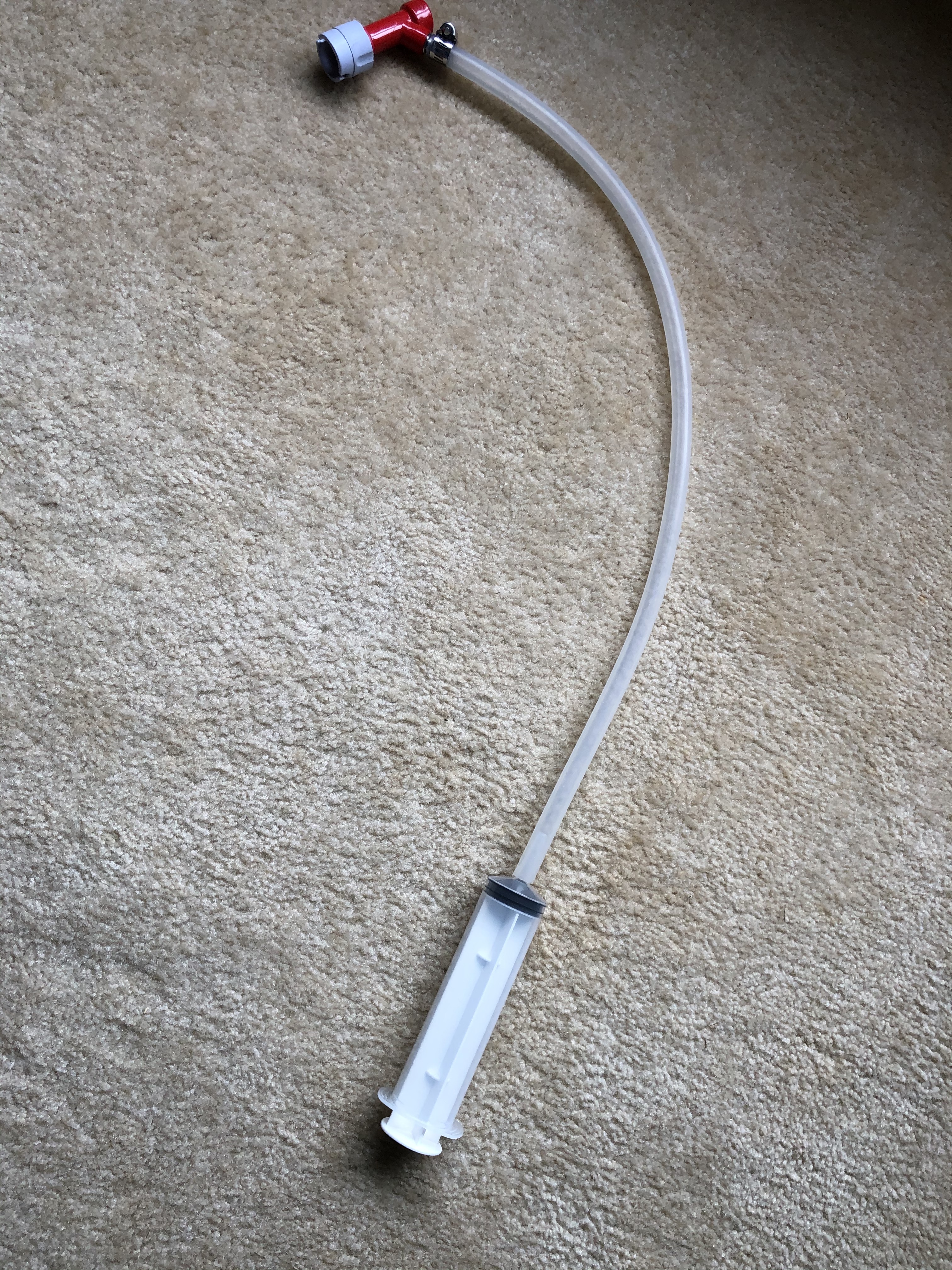

I remember seeing a post on HBT somewhere where someone posted a picture of a big syringe they use to inject gelatin into a keg. Has anyone seen it?

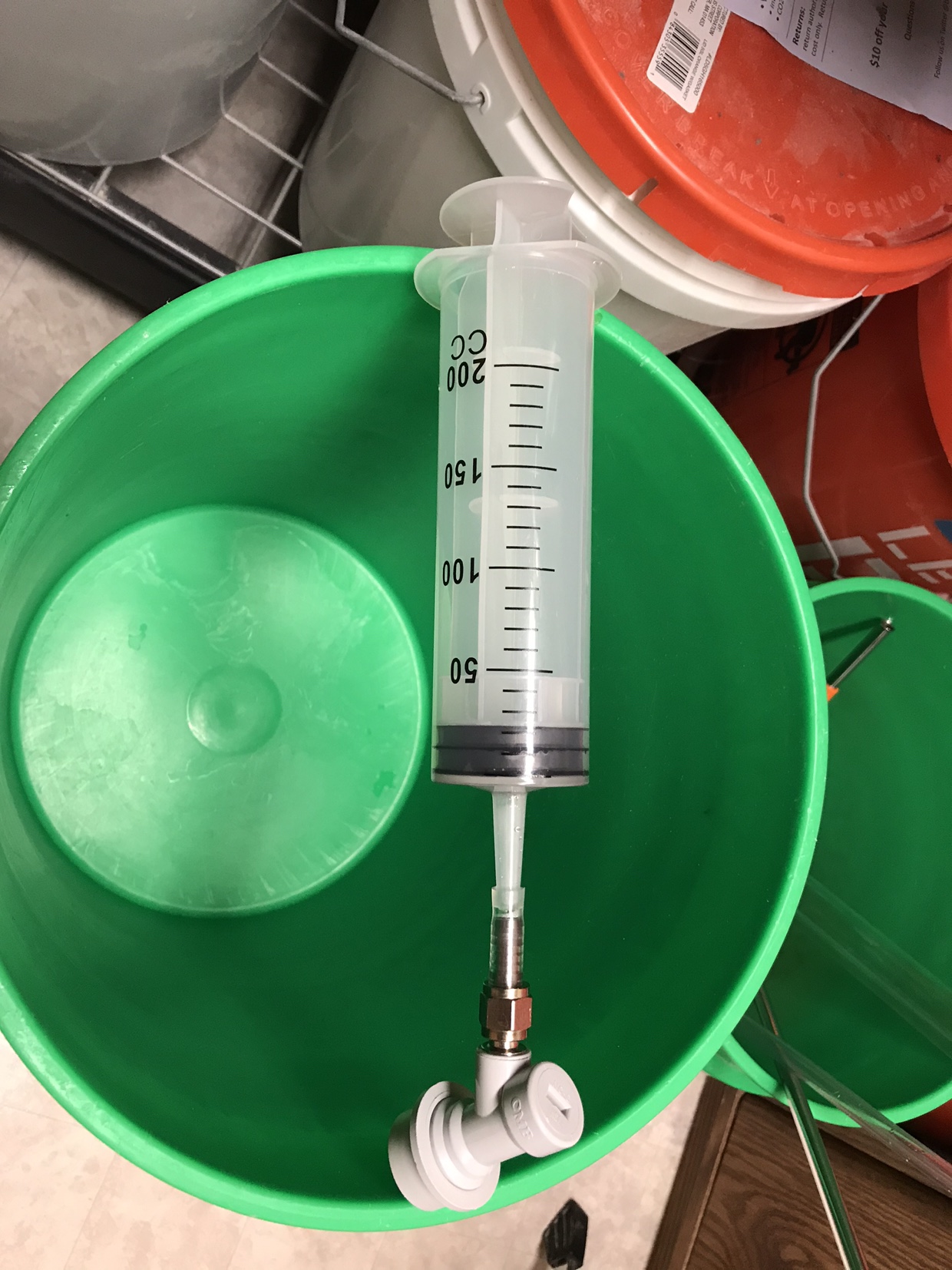

Better question - does anyone know of a big syringe that I can buy that readily hooks up to some tubing and the threaded corny keg posts?

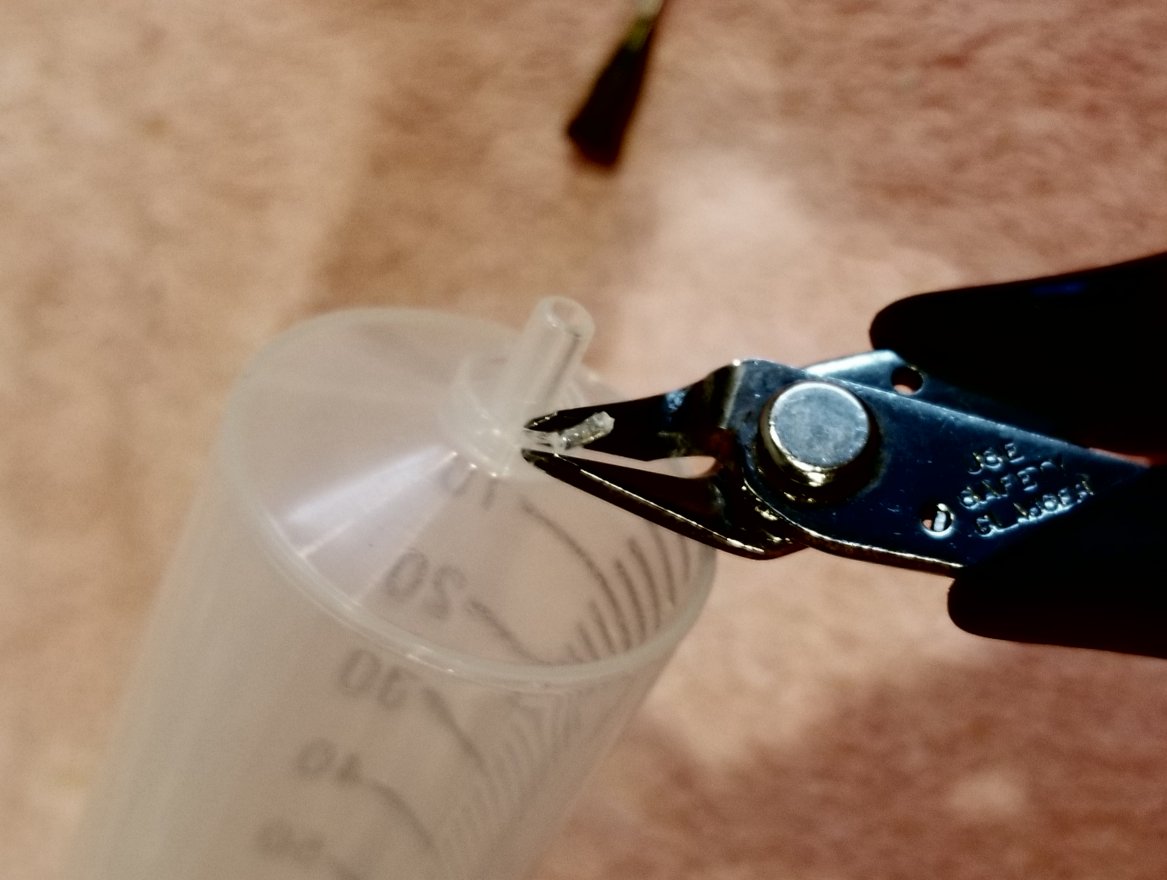

I bought these syringes to do that with but for the life of me, I can't figure out how to get this hooked up to a piece of tubing that will then hook up to one of the threaded corny keg posts. Any ideas?

Thanks.

Better question - does anyone know of a big syringe that I can buy that readily hooks up to some tubing and the threaded corny keg posts?

I bought these syringes to do that with but for the life of me, I can't figure out how to get this hooked up to a piece of tubing that will then hook up to one of the threaded corny keg posts. Any ideas?

Thanks.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)