andrewb_1985

Active Member

Hello,

My current Brew setup consists of 3 20gal pots with electric heaters and Herms coil.

With my setup when i step mash, it takes considerable time to increase the temp of my wort between steps. I have only done rests at 122 for protein rest so far and it takes me about 45 mins to raise from 122 to 155 where I normally sit for an additional hour before raising again for mash out. With a planned Hefe brew coming up I plan to use a Ferulic acid rest for the first time at 112F.

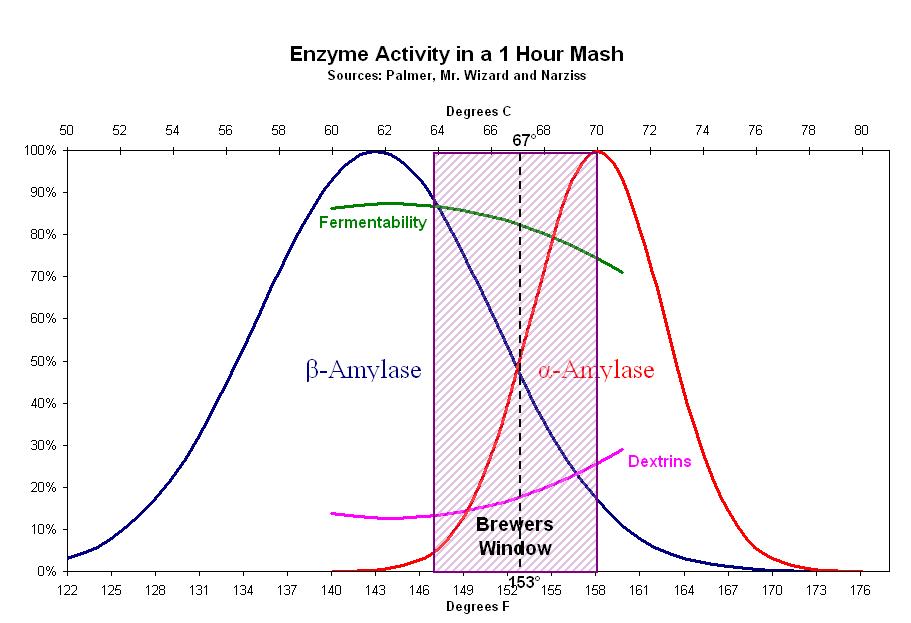

So my question is if I sit at 112 for 20 mins and then ramp straight to 168 over probably 1.5 hours for mash out, is there any gain anymore in staying at 155 for any amount of time?

And also is there any gain to a more rapid temp rise between steps? Ie if I added direct flame under mash tun to ramp more quickly. Because the way I see it with such a slow rise in temperature I'm basically doing protein, acid, b-amylase, a-amylase rests all in one.

Thoughts?

My current Brew setup consists of 3 20gal pots with electric heaters and Herms coil.

With my setup when i step mash, it takes considerable time to increase the temp of my wort between steps. I have only done rests at 122 for protein rest so far and it takes me about 45 mins to raise from 122 to 155 where I normally sit for an additional hour before raising again for mash out. With a planned Hefe brew coming up I plan to use a Ferulic acid rest for the first time at 112F.

So my question is if I sit at 112 for 20 mins and then ramp straight to 168 over probably 1.5 hours for mash out, is there any gain anymore in staying at 155 for any amount of time?

And also is there any gain to a more rapid temp rise between steps? Ie if I added direct flame under mash tun to ramp more quickly. Because the way I see it with such a slow rise in temperature I'm basically doing protein, acid, b-amylase, a-amylase rests all in one.

Thoughts?

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)