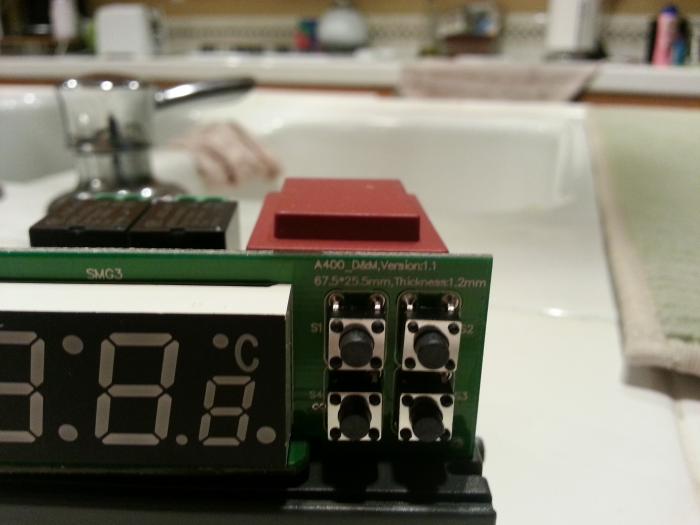

Will I need to worry about cleaning up the board at all if I attempt to use that approach?

Yes - you can try using a q-tip and some denatured alcohol or rubbing alcohol. Be careful to keep it off of the display, try and clean only the solder pads where your trying to make contact. Clean the back side of the board, where there are no components.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)