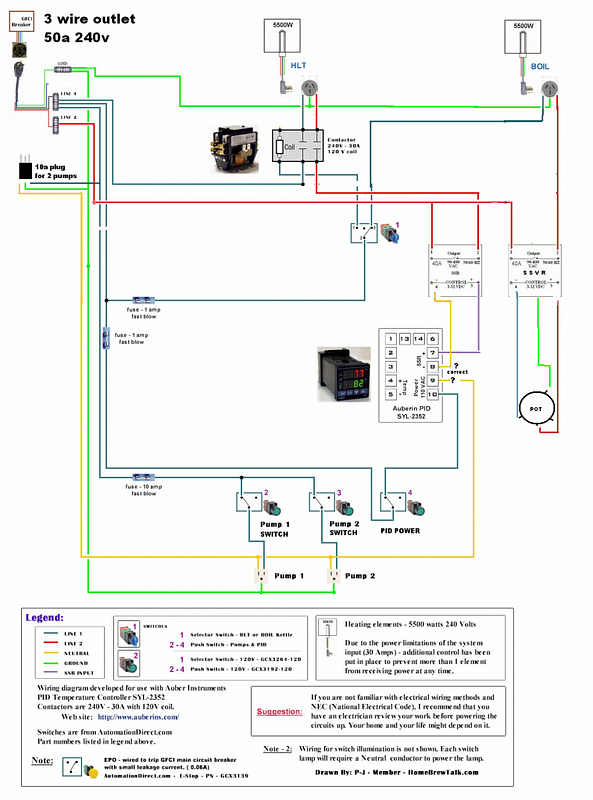

Ive started buying the basic parts for my electric controller.

-auber 2325

-rtd temp probe

-2 40a SSR

-2 120v contacter?

I plan to use 2 5500w elements in each HLT and BK.

HLT controlled by PID

BK controlled by PWM

2 pump outlets

3 way selector switch so that only one vessel can be controlled at a time.

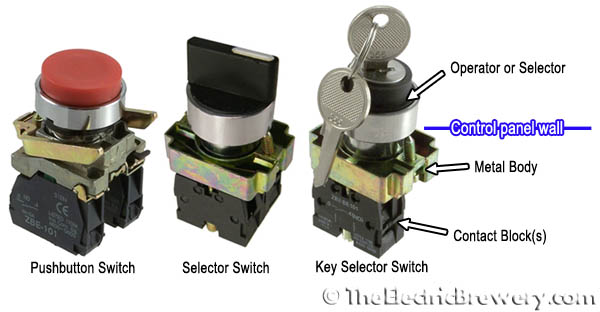

I'm having a hard time finding a selector switch rated for 50a. Also, I have a 3 wire 50a 240v outlet.

I'm still searching for plans so any diagrams and links will be helpful

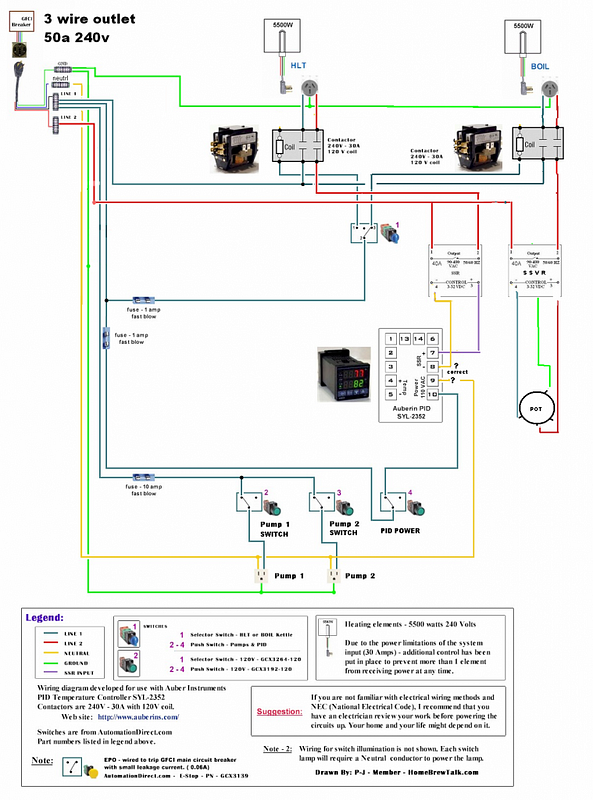

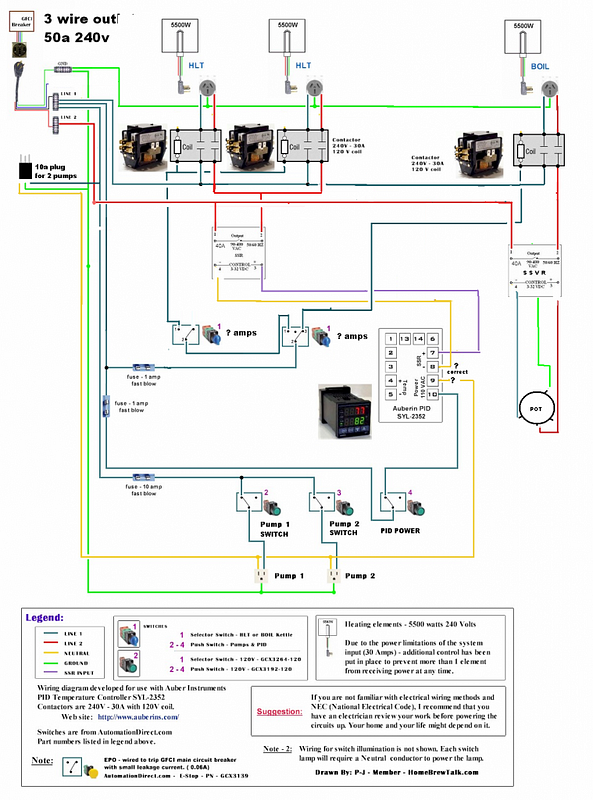

-auber 2325

-rtd temp probe

-2 40a SSR

-2 120v contacter?

I plan to use 2 5500w elements in each HLT and BK.

HLT controlled by PID

BK controlled by PWM

2 pump outlets

3 way selector switch so that only one vessel can be controlled at a time.

I'm having a hard time finding a selector switch rated for 50a. Also, I have a 3 wire 50a 240v outlet.

I'm still searching for plans so any diagrams and links will be helpful