You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

starting my build

- Thread starter BWN

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I used a 1" KO punch to put in holes for my pump outlets. I used these for outlets:

http://www.homedepot.com/Electrical...&langId=-1&storeId=10051&superSkuId=202887036

A 1" punch is just barely too small so I need to use a grinder or something to make the holes a little bigger. I took pictures but forgot to put the memory card in my camera. Tonight I will put in the holes for the RTD panel mount connectors and for the power cord. I hope to get it painted as well. Hopefully I will have pictures tomorrow morning. I am also looking for a way to attach the power cord to the hole in the panel. Any ideas?

http://www.homedepot.com/Electrical...&langId=-1&storeId=10051&superSkuId=202887036

A 1" punch is just barely too small so I need to use a grinder or something to make the holes a little bigger. I took pictures but forgot to put the memory card in my camera. Tonight I will put in the holes for the RTD panel mount connectors and for the power cord. I hope to get it painted as well. Hopefully I will have pictures tomorrow morning. I am also looking for a way to attach the power cord to the hole in the panel. Any ideas?

I used a 1" KO punch to put in holes for my pump outlets. I used these for outlets:

http://www.homedepot.com/Electrical...&langId=-1&storeId=10051&superSkuId=202887036

A 1" punch is just barely too small so I need to use a grinder or something to make the holes a little bigger. I took pictures but forgot to put the memory card in my camera. Tonight I will put in the holes for the RTD panel mount connectors and for the power cord. I hope to get it painted as well. Hopefully I will have pictures tomorrow morning. I am also looking for a way to attach the power cord to the hole in the panel. Any ideas?

Brian,

I have Green Lee punch set: 1/2", 3/4", 1" ans 1 1/4" if you need to use them for that?

BE EXTRA CAREFUL IF YOU'RE GOING TO USE A CONDUIT PUNCH!

I used a 1-1/4" conduit punch which resulted in a 1-7/8" hole. That why I am all welded, now.

w00t!

This.

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Yes I plan on using the punches for my kegs. I need to get a larger drill bit for the pilot holes.

If you have the harbor freight conduit punch set, I used the second to largest one for the electric element, I think it's a 1". The 1/2" works great for ball valves, makes a perfect 7/8" hole. I also used the 3/4 to punch the perfect size hole for the pump outlets like you have above. I guess conduit punches and chassis punches are different size.

Harbor Freight punch sets are "Electrical Conduit Punches" & punch a hole for the conduit fitting.If you have the harbor freight conduit punch set, I used the second to largest one for the electric element, I think it's a 1". The 1/2" works great for ball valves, makes a perfect 7/8" hole. I also used the 3/4 to punch the perfect size hole for the pump outlets like you have above. I guess conduit punches and chassis punches are different size.

Here are the stated sizes and the actual hole size:

Die - Actual Hole

1/2" = 7/8"

3/4" = 1-3/32"

1" = 1-11/32"

1-1/4" = 1-11/16"

So, with that stated, be very careful.

I'll have to wait until I get my elements before I put a hole in the keg. I got my heat sinks mounted along with my element receptacles and pump receptacles. I have pictures but am at work and will have to wait until I get home to post them. I think I have spent 8 to 10 hours measuring, drilling, cutting, reaming, punching and filing holes for this thing. The worst part is I spent all that time measuring it over and over to get it perfect but the drill bit would wander a little and throw everything off.

Did you center punch the spot pre-drill?

No, live and learn I guess

BWN said:Here are the pictures of the heat sinks and receptacles. I left the bottom pump receptacle out because of the way I put them the hot screw will be too low to attach a wire with it in place.

What size of screws did you use to mount your heat sink, having issues with this. I got a ton done today check out my thread. Hope all is well. Will try to finish up the last three holes for panel and paint tomorrow.

BWN said:I used the ones that came with it. I used the heat sinks from Auber it is actually 2 next to each other.

Ok thanks yeah I bought a larger one and need to get some betters screws to mount the SSRs thanks

Looking good man. I will give you a call when I get back next week about the wire. thanks.

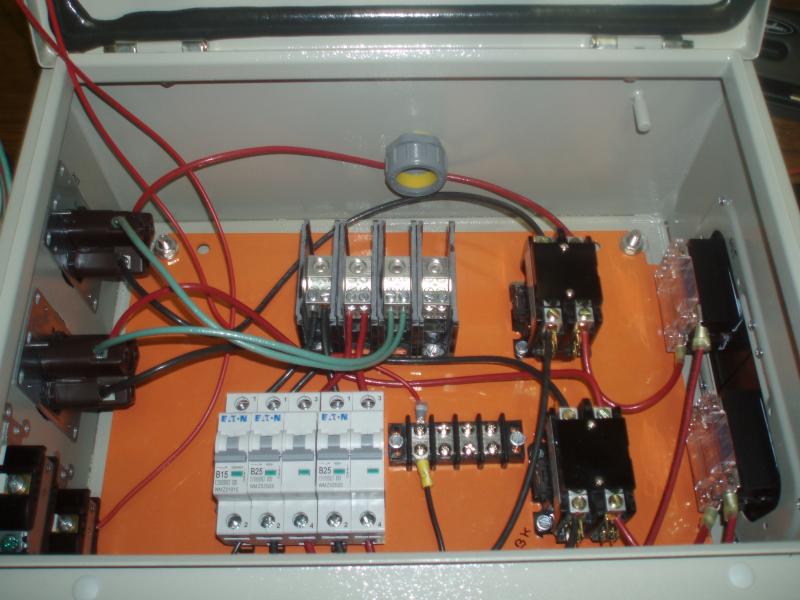

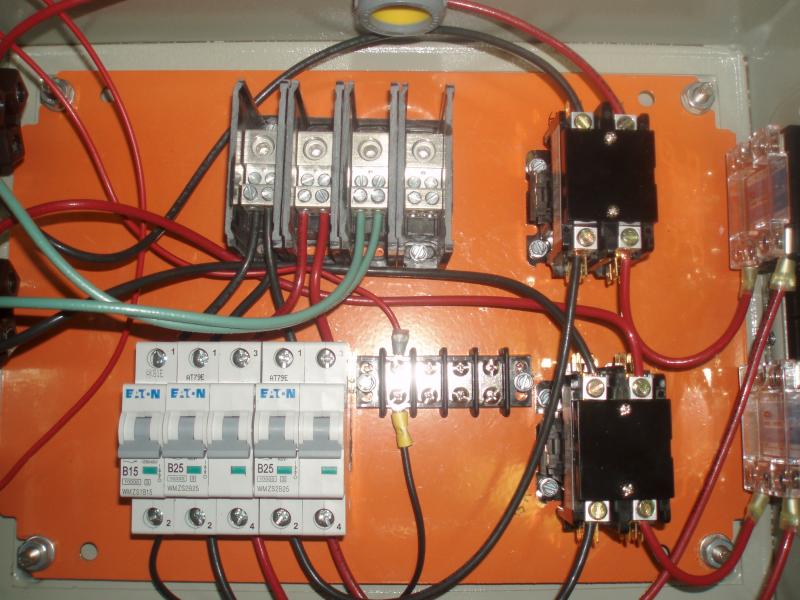

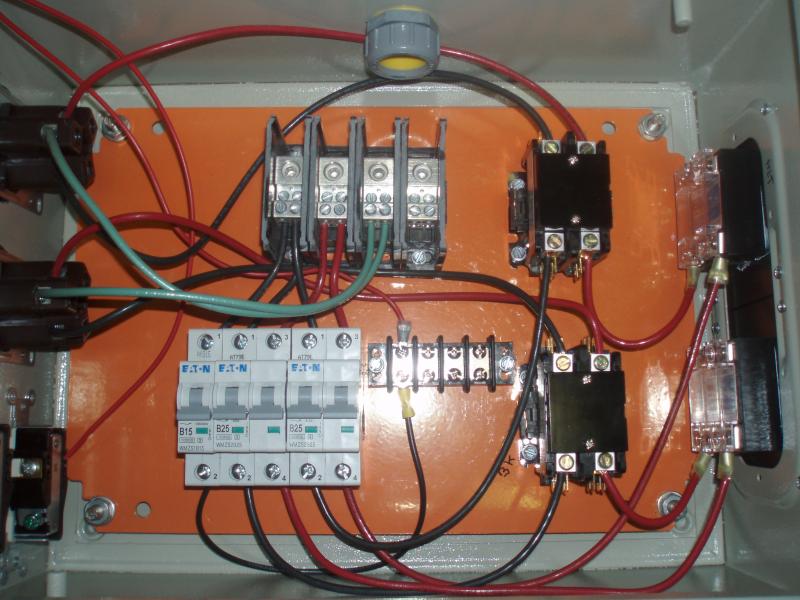

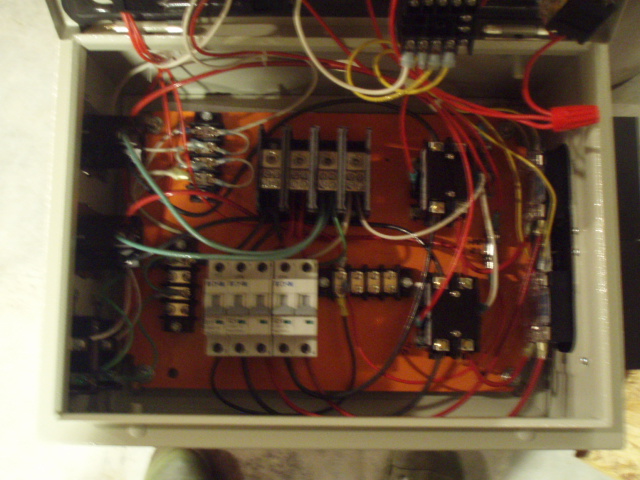

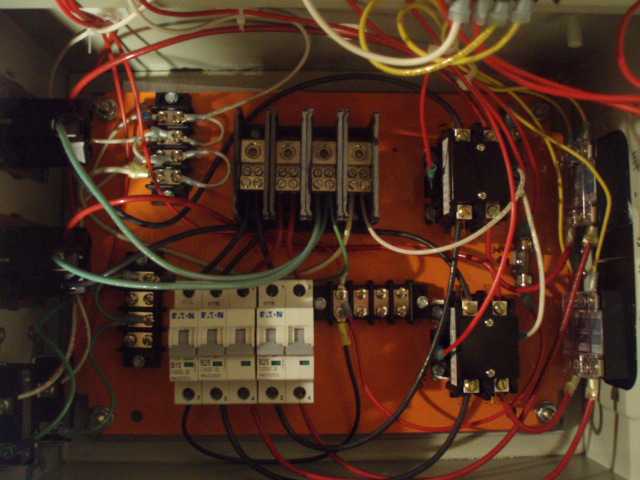

I have almost all my wiring done. What size wire should I use from the switches for the elements to the coil on the contactors? I have 14 gauge going to the switches protected by a 1 amp fuse. I assume 14 gauge to the coil should be ok right?

Looking good, I am out again for another trip but hope to button up my wiring when I return. Great job.

Get it done and fire it up!

Looks good.

Looks good.

Just saw your other post I have been gone alot and haven't done much I need to stop over and check out your progress one of these days!

Similar threads

- Replies

- 12

- Views

- 3K

North Carolina

Electric Brewing Control Panel

- Replies

- 8

- Views

- 3K

- Replies

- 42

- Views

- 9K

Latest posts

-

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: madscientist451

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)