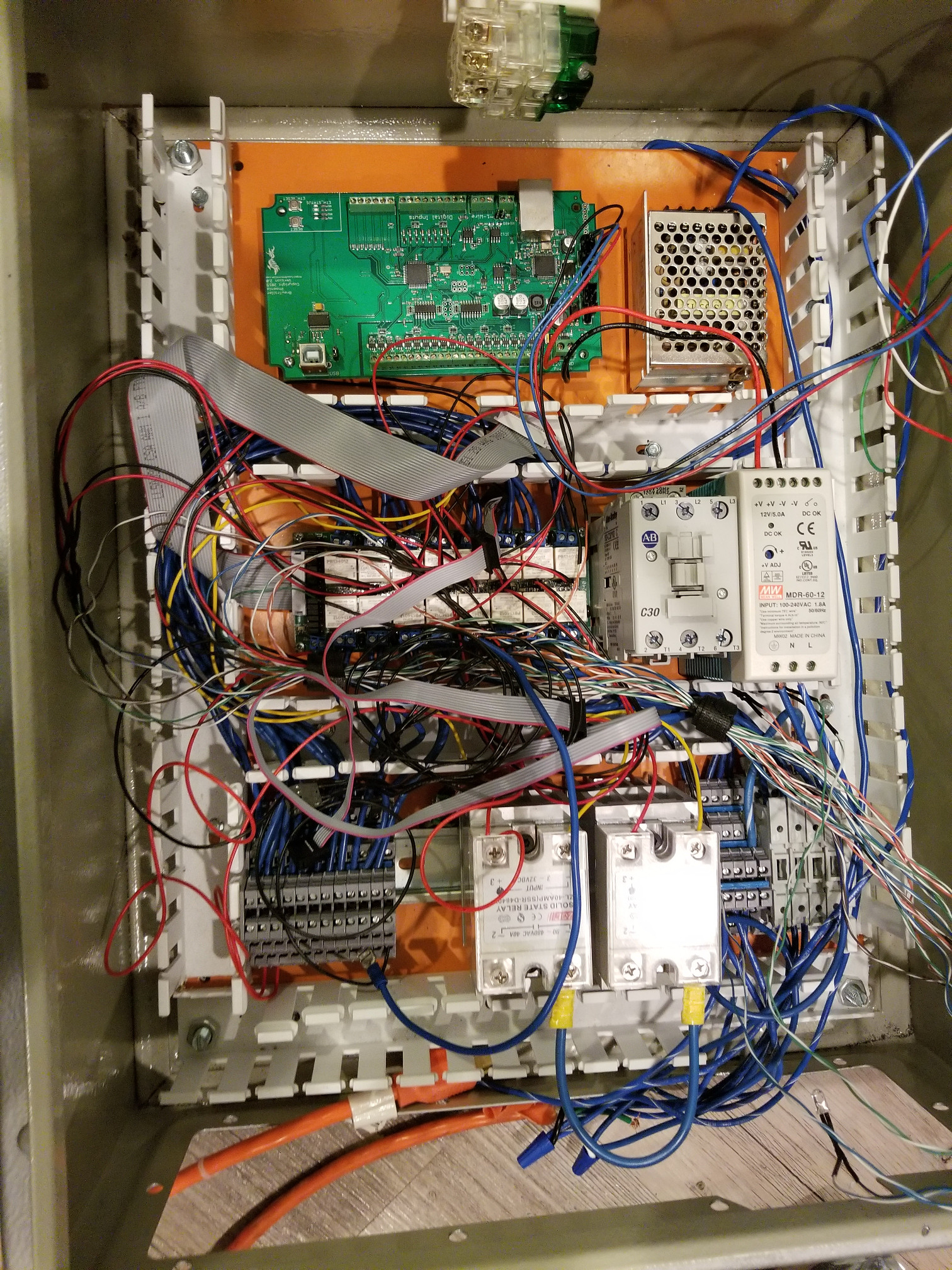

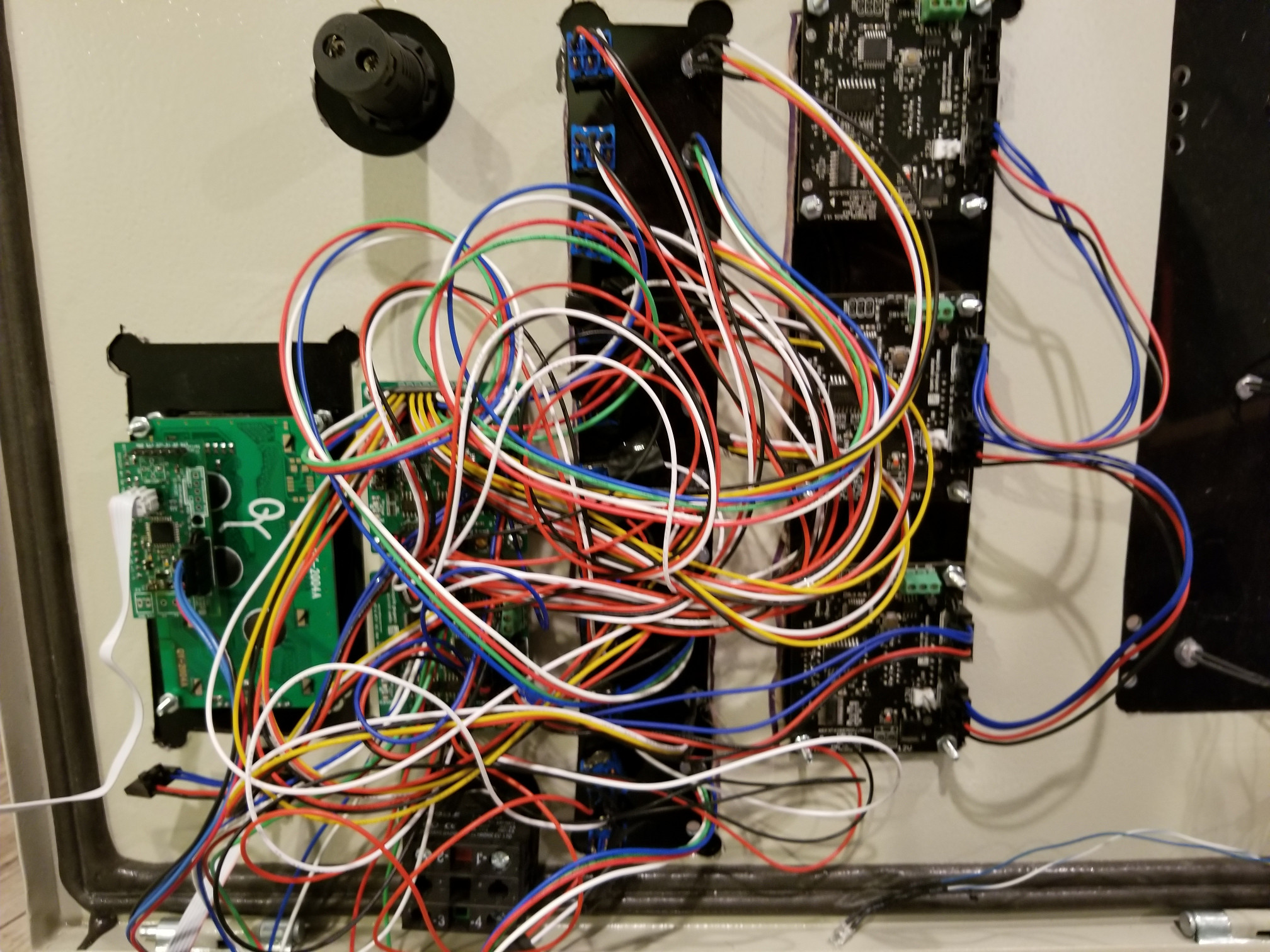

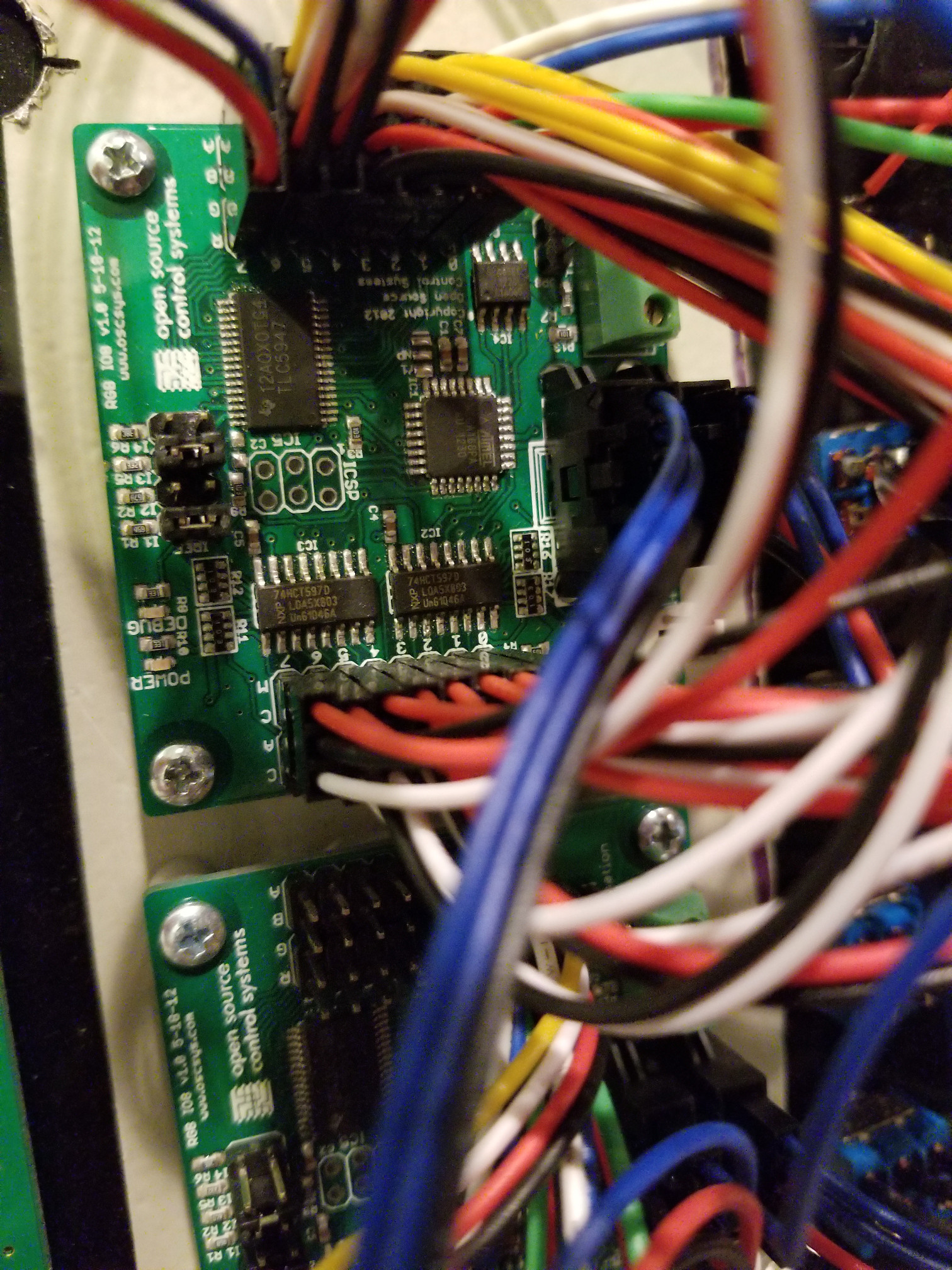

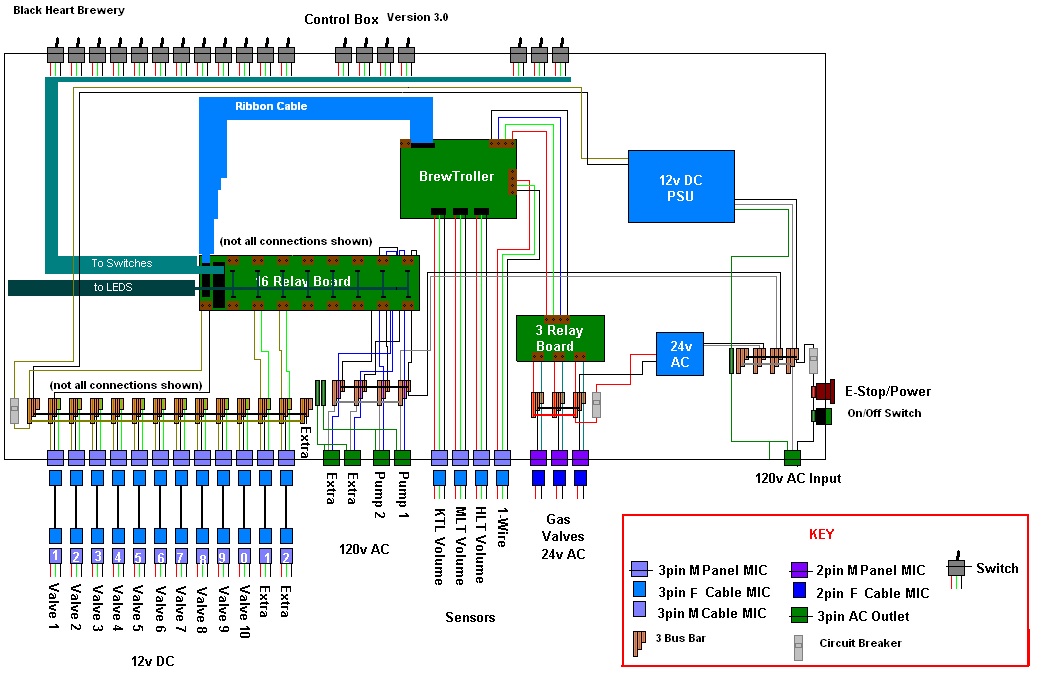

Hello wise automated folks! I need your advice and guidance. I have a system all rigged up with a HLT, mash tun, boil kettle, 3 pumps, automated valves, temp sensors etc that was supposed to use brewtroller to function. From reading through the forum way back in the day, it seemed like it was something I could handle...until stuff didn't work. The board didn't work, flashing firmware lead to a dead board, buy new board and hook it up and it doesn't work. Get frustrated, quit on it for 6 months, redo wiring, get new modules, stuff gets outdated or is unavailable....

So, here I am after 9 years of off and on tinkering, still with no working brew system. It seems like my biggest problem is working with the controller itself and the modules. I have no idea how to code/compile or do any of that stuff. Honestly it's the worst feeling when I follow the instructions blindly and get stuck when it doesnt work (which has really been the past 7 years off/on for me). My question to you all:

1) is there a control system out the that I could plug and play with what I have? I dont mind stripping out the guts of my control panel. It seems like Bru control is popular, but it looks like coding/Arduino expertise is needed. Thoughts?

2) Should I just give up and buy a Picobrew thing? This hurts me bad, but maybe it's the best option.

Help!

So, here I am after 9 years of off and on tinkering, still with no working brew system. It seems like my biggest problem is working with the controller itself and the modules. I have no idea how to code/compile or do any of that stuff. Honestly it's the worst feeling when I follow the instructions blindly and get stuck when it doesnt work (which has really been the past 7 years off/on for me). My question to you all:

1) is there a control system out the that I could plug and play with what I have? I dont mind stripping out the guts of my control panel. It seems like Bru control is popular, but it looks like coding/Arduino expertise is needed. Thoughts?

2) Should I just give up and buy a Picobrew thing? This hurts me bad, but maybe it's the best option.

Help!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)