invictusbrew

Well-Known Member

- Joined

- Jun 12, 2013

- Messages

- 349

- Reaction score

- 95

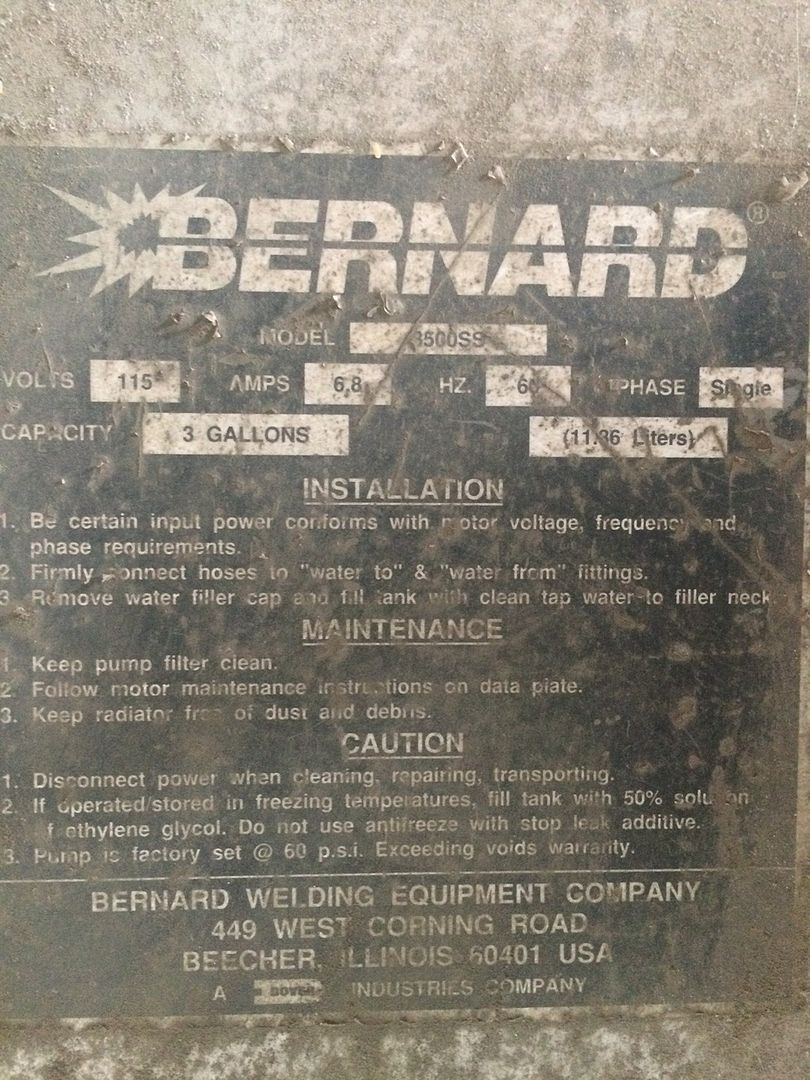

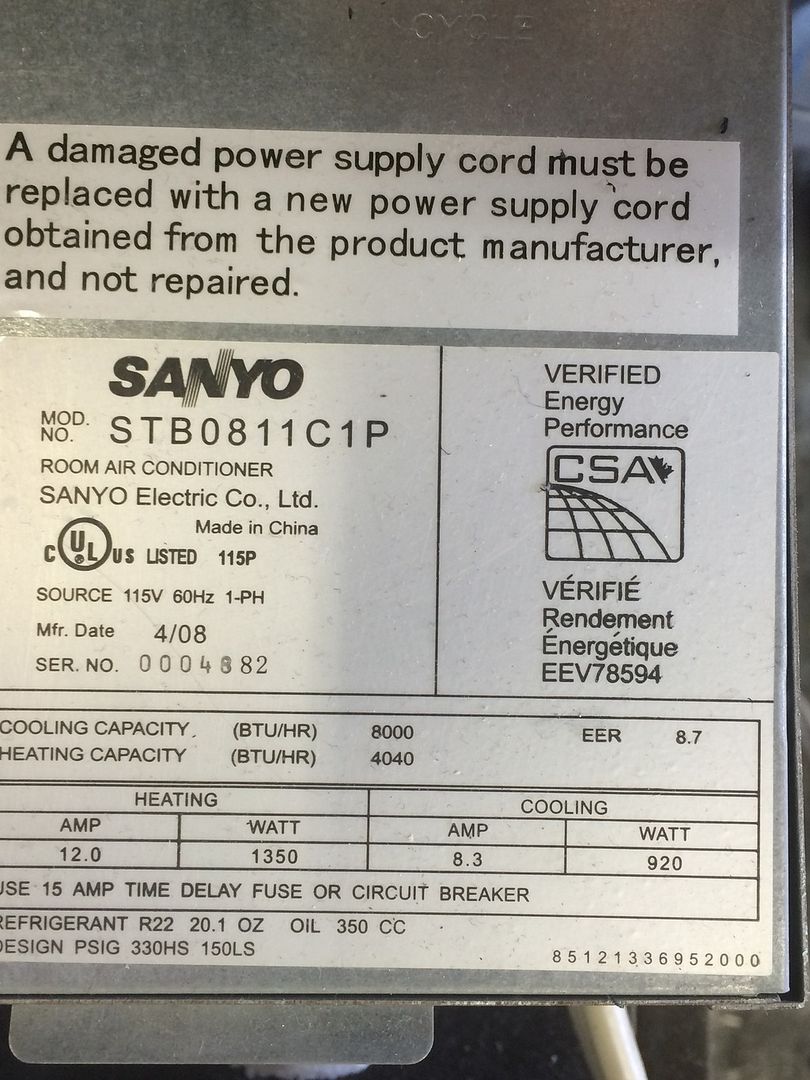

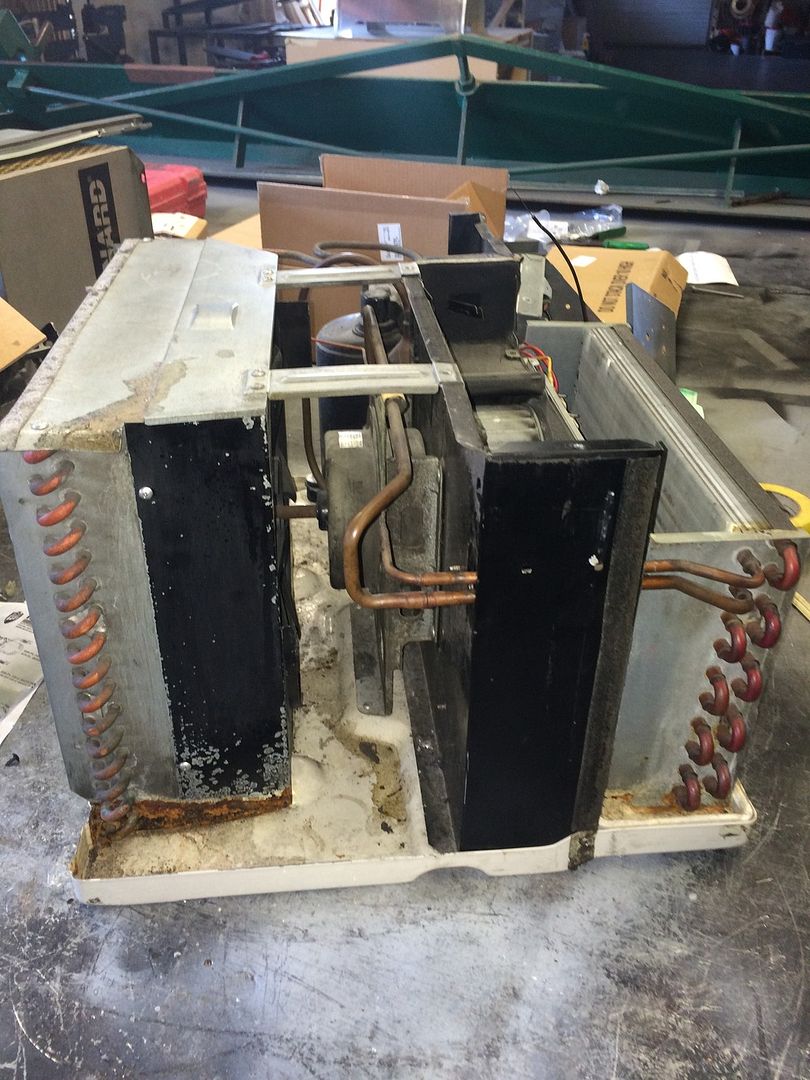

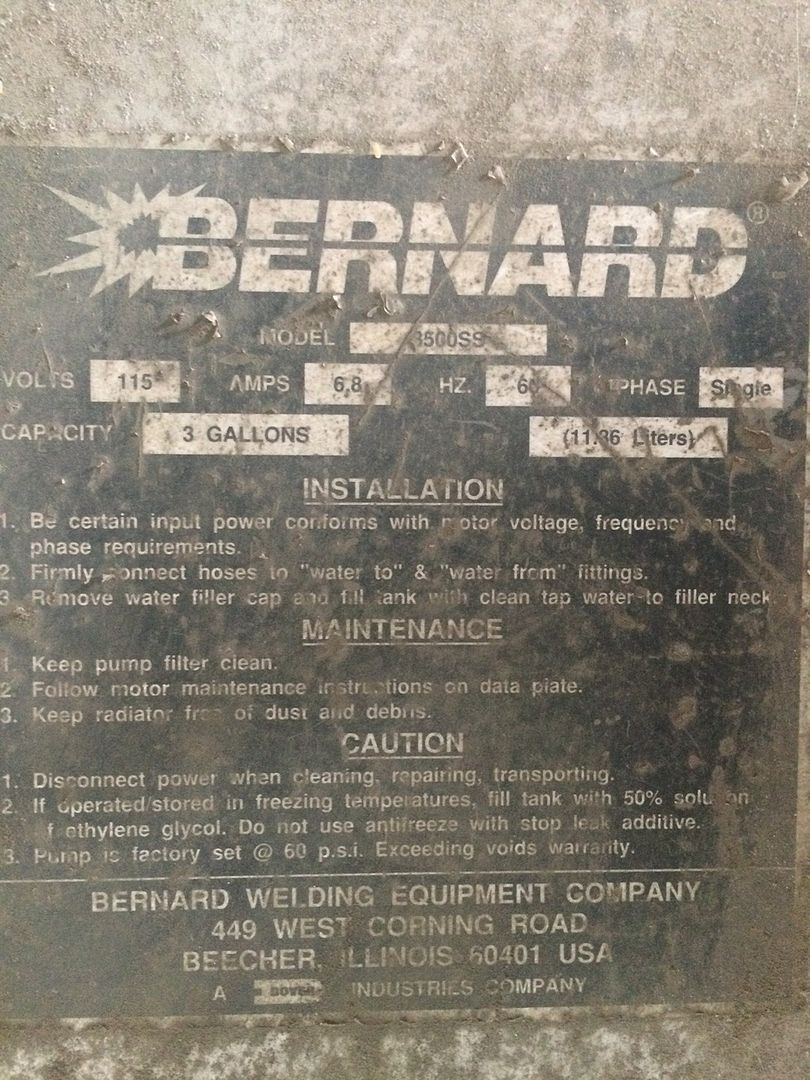

So, I have an old spot welder I no longer use (a few of them really, but one in particular) that I'm looking to possibly take the cooler off of and utilize it as a glycol chiller for my 28 gal conical fermenter. Since I'm not too well versed in how this particular style of pump works (I mean that more as in efficiency, not in mechanics), I was wondering if someone may have some more insight on whether this will work or not, and if so, what I may need to do to make it fit my needs. If at all possible, I would absolutely love to make this work for two fermenters... but haven't really looked into the logistics of such a thing just yet.

Any and all input on this would be much appreciated, thank you all in advance!

Any and all input on this would be much appreciated, thank you all in advance!