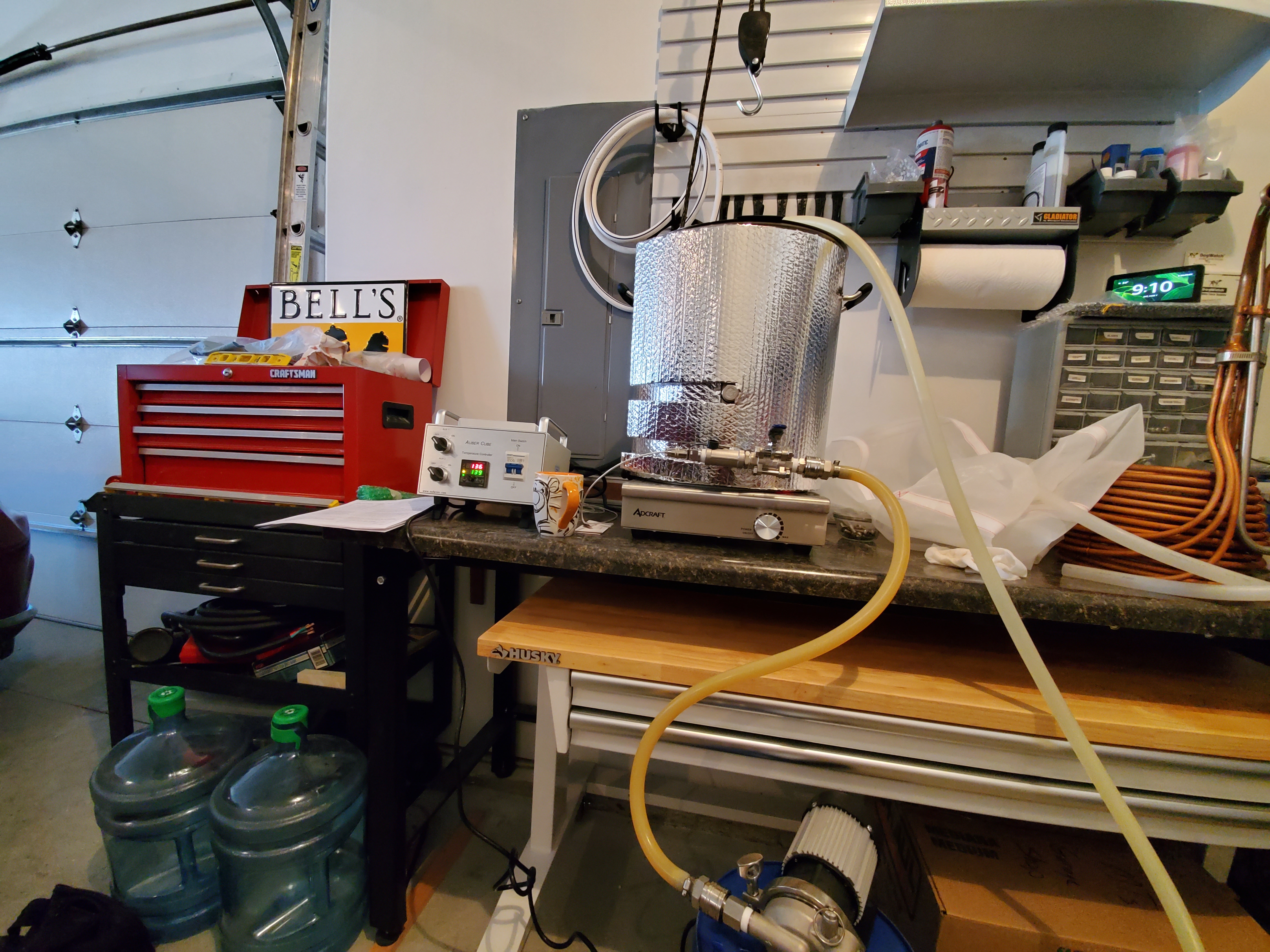

I've gone through a similar journey as you. I've been considering getting the C208V for years, as it seems like the best option for a fully controllable induction mashing system, but am always afraid to use it on 240v. I keep checking here every few months to see what the verdict is from those braver than me, and have indeed seen several people who've used it successfully. Still... it worries me. I actually contacted Adcraft and asked if it could be used on 240v, hoping that there would be some input tolerance that would make it okay, but was informed that it could be 208 only. Now... that's the company's official "safe" stance on things, so I understand there is likely a lot of gray area around the truth from an actual engineering perspective.

Another option I've considered is to modify a 240v induction plate in some way to allow for external control. The most hardcore way would be to bypass the control circuit entirely and strike the induction coil directly... but that seems like way too much work and quite dangerous/likely to fail. The second, safer option would be to augment/modify the control panel to simulate keypresses externally. Even "on/off" should be sufficient, as most induction plates will start up at 50% power when turned on. That's fine if all you need to do is inject some heat for a minute or so. Finally, what might actually be the best option IMO, because it doesn't involve modifying the device at all, but is a little clumsier, would be to build something which mechanically controls the control panel from a computer source. Something like a servo or stepper motor. With the Adcraft, it actually wouldn't be too difficult to attach a motor to the shaft of the power knob on the front, and then just calibrate its position across the power spectrum. Another benefit of these control-panel-intercept solutions is that, since the main cooktop circuit is never completely cut (as in a traditional on/off control circuit), the fan keeps running. I've noticed that on most cooktops, the fan keeps running for some time after the coil is de-energized, which helps to cool the unit down.

On another note, with your Auber, was it configured to power the Adcraft as a simple on/off switch, or is it trying to modulate the voltage/power output as you would with an actual PID controller hooked up to an immersion element? I ask because resistive heating elements are modulated by varying the power applied to them as a function of their voltage/current, but an induction plate requires full power all the time which is then further modulated by the internal circuitry. If your Cube was setup for an immersion element, it would probably cause the kind of error you described, with the Adcraft freaking out over the input power being unstable.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)