GotPushrods

Well-Known Member

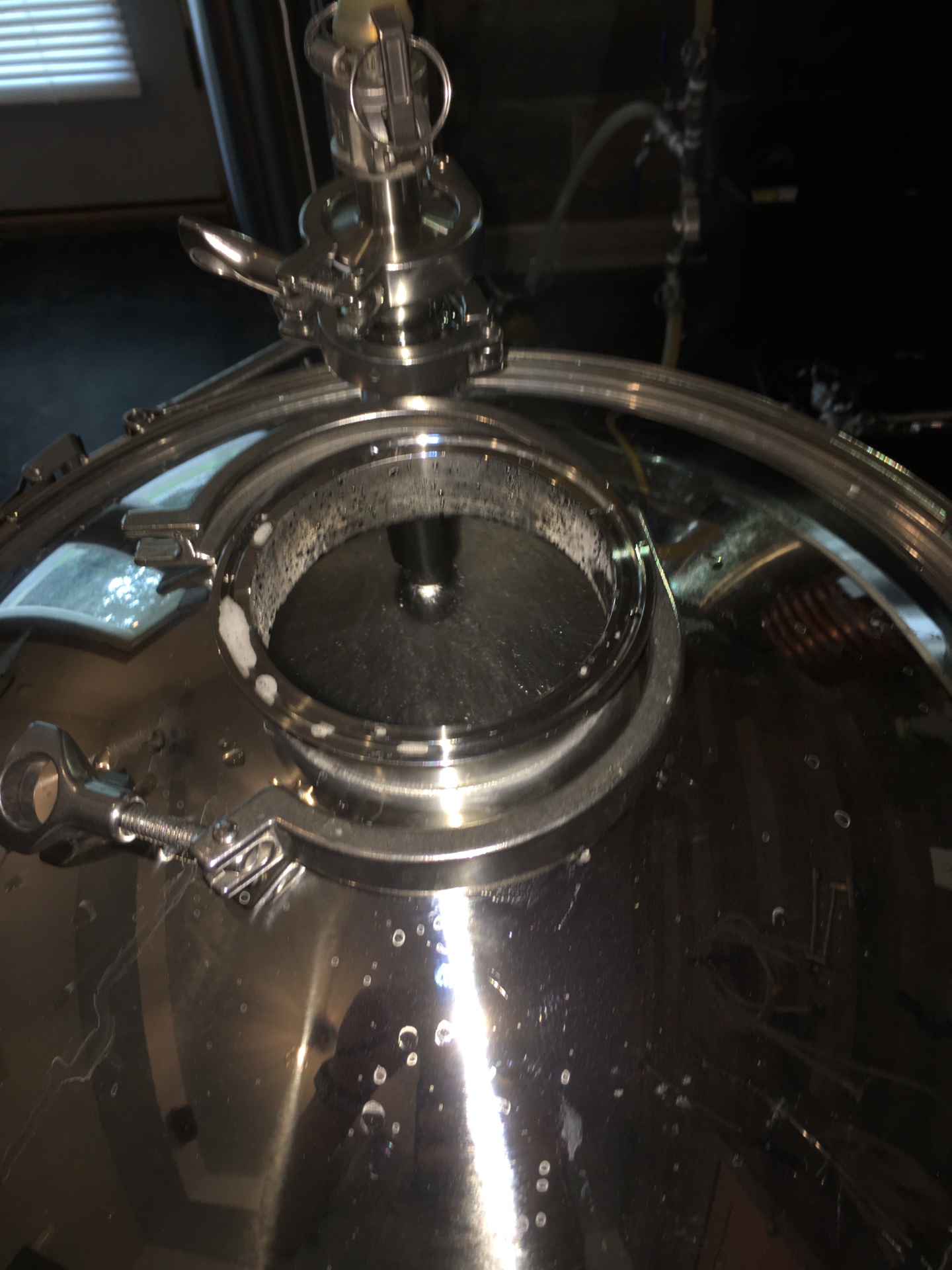

So what are the details from the pressure test? You now have it listed at 15 psi working pressure. Where did it burst... 30 psi? What was the failure mode? Weld? Tri-clover? Middle of the tank?

If I set a PRV to 15 psi to spund, is pressure damage warrantied?

If I set a PRV to 15 psi to spund, is pressure damage warrantied?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)