I'm itching to use mine . Gonna brew something within the next couple weeks .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spike fermenters.

- Thread starter Jag75

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

@Blazinlow86 , just ordered the 2"barbed and hose for dumping yeast . Looking forward to not having to use hop bags anymore .

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

How are you guys using the racking arm? I have done numerous batches without it but not sure what angle the arm need to be when racking?

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I use it in the down position. I also do a dump the day before racking typically. CheersHow are you guys using the racking arm? I have done numerous batches without it but not sure what angle the arm need to be when racking?

Are you supposed to start racking with it up then slowly work it down?

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

Are you supposed to start racking with it up then slowly work it down?

This is what I was getting at, can you loosen the racking clamp and rotate the racking arm or would beer pour out causing mass hysteria?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

I bet he has it in the down position because he dumps prior and isnt worried about transferring gunk .

Heck now I'm wondering if I really needed the racking arm lol

Heck now I'm wondering if I really needed the racking arm lol

CodeSection

Well-Known Member

- Joined

- Feb 4, 2018

- Messages

- 1,655

- Reaction score

- 819

This is what I was getting at, can you loosen the racking clamp and rotate the racking arm or would beer pour out causing mass hysteria?

If you loosen the racking arm so that you can just rotate it, no beer will leak out. I dump some trub into Spike's 2" sight glass prior to racking. Then I rotate the racking arm to the side. IMO, if you dump too much trub before racking, you are wasting beer since the beer mostly likely will go below the racking arm or port....

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

The only real benefit I can see to the racking arm is I noticed trub would settle in the conical port. Having the arm extended gets it away from the port. I just plan on having it pointed straight down.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

If your dumping prior to racking the reasons to use the arm is to get most of the beer out of the cone but additional and most importantly it prevents trub getting into your pin/ball connectors/ serving kegs and plugging them which is a real pain. It's a must have imho. After spending this amount of money to still deal with plugged connector and sediment in the kegs would be unacceptable for myself. CheersThe only real benefit I can see to the racking arm is I noticed trub would settle in the conical port. Having the arm extended gets it away from the port. I just plan on having it pointed straight down.

If your dumping prior to racking the reasons to use the arm is to get most of the beer out of the cone but additional and most importantly it prevents trub getting into your pin/ball connectors/ serving kegs and plugging them which is a real pain. It's a must have imho. After spending this amount of money to still deal with plugged connector and sediment in the kegs would be unacceptable for myself. Cheers

Ok with that racking arm trub cant fall into that section . And when you turn it down it allows you to get most of the beer out. I understand what your saying . This is new to me and apparently others too lol. I appreciate you explaining how these fermenters work .

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

Anytime. CheersOk with that racking arm trub cant fall into that section . And when you turn it down it allows you to get most of the beer out. I understand what your saying . This is new to me and apparently others too lol. I appreciate you explaining how these fermenters work .

CodeSection

Well-Known Member

- Joined

- Feb 4, 2018

- Messages

- 1,655

- Reaction score

- 819

...This is new to me ...

This link may help... https://spikebrewing.freshdesk.com/...es/35000043191-positioning-of-the-racking-arm

@CodeSection , thanks for that link !

- Joined

- Feb 10, 2019

- Messages

- 160

- Reaction score

- 183

I’m a noob still to the conical, but have used it exactly twice.

Both instances I’ve started fermenting with the racking port at least slightly down (trying not to “collect” too much trub in the racking arm).

Before racking I did a dump of the conical. Especially with the items you bought (2” to 1/2” QD) I did not see a lot of loss from trub dumping- about 1/2 gallon max (Probably more like 1/4 gallon, although it isn’t negligible) as long as you are careful. I pressed 5-10 psi on top and cycled the bottom drain open/closed until I got the sight glass kind-of clear. Literally I did just enough to ensure the trub line was below the racking port (can’t actually see it, but just dumping some to see clearish beer in the 2” sight glass, or the tubing if you don’t have the glass).

When racking I rotated the arm up (just above horizontal really) and racked, rotating down while monitoring the tubing for signs of trub.

I started with the normal, stock TC gaskets that came with the conical for the first transfer, harder to rotate the racking arm, but just don’t go crazy loosening the TC clamp and test it every half turn or so while loosening, if you see any leakage I would stop (I didn’t get uncomfortably loose and was able to rotate with a little force, but it takes a little to “break” it free and then moves better). For the second brew I bought a Teflon TC gasket from MoreBeer (https://www.morebeer.com/products/triclamp-gasket-teflon-15.html) which made turning it much easier with less loosening and made me feel less nervous. This is a replacement for the unitank-to-racking arm clamp.

Both instances I’ve started fermenting with the racking port at least slightly down (trying not to “collect” too much trub in the racking arm).

Before racking I did a dump of the conical. Especially with the items you bought (2” to 1/2” QD) I did not see a lot of loss from trub dumping- about 1/2 gallon max (Probably more like 1/4 gallon, although it isn’t negligible) as long as you are careful. I pressed 5-10 psi on top and cycled the bottom drain open/closed until I got the sight glass kind-of clear. Literally I did just enough to ensure the trub line was below the racking port (can’t actually see it, but just dumping some to see clearish beer in the 2” sight glass, or the tubing if you don’t have the glass).

When racking I rotated the arm up (just above horizontal really) and racked, rotating down while monitoring the tubing for signs of trub.

I started with the normal, stock TC gaskets that came with the conical for the first transfer, harder to rotate the racking arm, but just don’t go crazy loosening the TC clamp and test it every half turn or so while loosening, if you see any leakage I would stop (I didn’t get uncomfortably loose and was able to rotate with a little force, but it takes a little to “break” it free and then moves better). For the second brew I bought a Teflon TC gasket from MoreBeer (https://www.morebeer.com/products/triclamp-gasket-teflon-15.html) which made turning it much easier with less loosening and made me feel less nervous. This is a replacement for the unitank-to-racking arm clamp.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

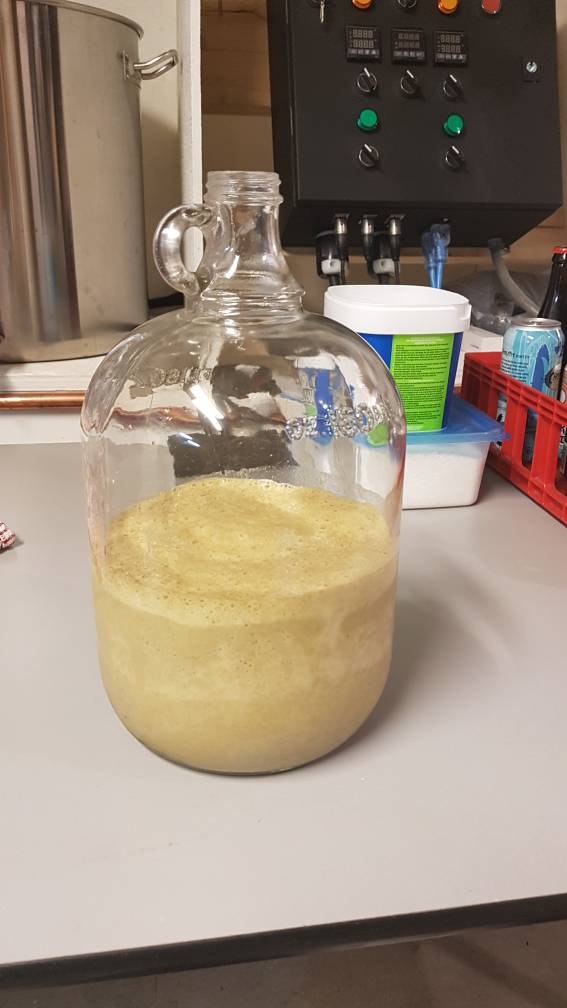

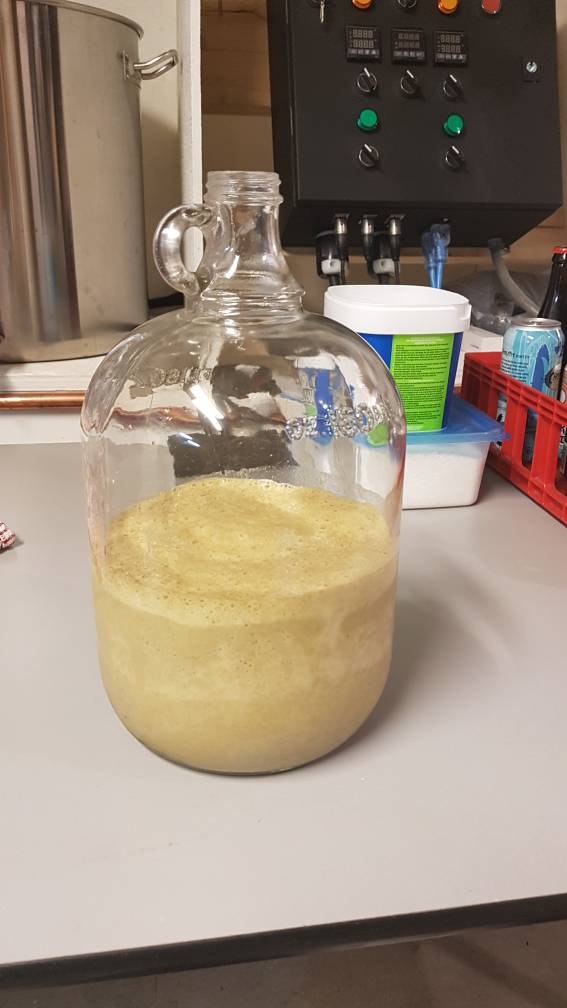

Theres what the dump looks like after cold crashing for 48hrs and stopping immediately when clean beer comes out. Cheers

Nice ^^^^^^

So I'm a member of the Spike user's group on Facebook, and in the past week I've seen 3 people post that their lid gaskets won't hold pressure. One guy was even saying his lid gasket would blow out violently when he hit 9 PSI as verified by 2 different pressure gauges.

Is this a common problem that you all have experienced? Is this a design flaw that future buyers should be aware of?

Is this a common problem that you all have experienced? Is this a design flaw that future buyers should be aware of?

I haven't used mine yet . However the original seal would do that . A guy on YouTube did a review . Spike changed the design of the gasket and he said it was way better and worked perfectly. Dont know when they changed to the new style.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I have never had any issues with the lid leaking on mine. Additionally my lid gasket fits tightly and does not fall out when the lids flipped. I would say it's a defective unit or there doing something incorrectly. I can't think of how the gasket could even come out when the clamps on. CheersSo I'm a member of the Spike user's group on Facebook, and in the past week I've seen 3 people post that their lid gaskets won't hold pressure. One guy was even saying his lid gasket would blow out violently when he hit 9 PSI as verified by 2 different pressure gauges.

Is this a common problem that you all have experienced? Is this a design flaw that future buyers should be aware of?

awoitte

Well-Known Member

- Joined

- May 9, 2017

- Messages

- 184

- Reaction score

- 21

By the time I'm ready to cold crash the psi has built up to around 10psi naturally.

... however if the psi was to drop to 0 and the fermentor is sealed you could crush it so be mindful when dropping temps with a sealed vessle.

By naturally do you mean you have co2 connected..?

Crushing a conical is one of my biggest fears. Is it only when going down in temperature that this may be a problem? How can a person operate to make sure this never happens?

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

Just ensure you always have positive pressure while dropping the temp down. CheersBy naturally do you mean you have co2 connected..?

Crushing a conical is one of my biggest fears. Is it only when going down in temperature that this may be a problem? How can a person operate to make sure this never happens?

- Joined

- Feb 10, 2019

- Messages

- 160

- Reaction score

- 183

By naturally do you mean you have co2 connected..?

Crushing a conical is one of my biggest fears. Is it only when going down in temperature that this may be a problem? How can a person operate to make sure this never happens?

Positive pressure is best for it. Otherwise, don’t have it sealed, but then you’ll get air pulling in or sanitizer suck-back (depending on the arrangement), so that isn’t actually an option.

awoitte

Well-Known Member

- Joined

- May 9, 2017

- Messages

- 184

- Reaction score

- 21

So does that mean pressure lessens as temperature drops? And if so, at what rate? At first I thought: to have positive pressure I'd need to make sure there was enough co2 in there to not be completely absorbed by the liquid in addition to it changing due to pressure drop. I feel like its better to just have co2 feeding into it at a certain pressure. If that is the case then what is the minimum it should be to make sure my baby doesn't get crushed.Just ensure you always have positive pressure while dropping the temp down. Cheers

I noticed it was about every other day I had to add some co2 to keep the psi @11. That was maintaining a temp of 55f .

It wasnt a lot of co2 just about 4-2 psi at a time

It wasnt a lot of co2 just about 4-2 psi at a time

- Joined

- Feb 10, 2019

- Messages

- 160

- Reaction score

- 183

So does that mean pressure lessens as temperature drops? And if so, at what rate? At first I thought: to have positive pressure I'd need to make sure there was enough co2 in there to not be completely absorbed by the liquid in addition to it changing due to pressure drop. I feel like its better to just have co2 feeding into it at a certain pressure. If that is the case then what is the minimum it should be to make sure my baby doesn't get crushed.

Someone can correct me if needed, but two things at play-

1. CO2 is more readily absorbed into the beer at lower temps

2. Volume shrinks a little when lowering temperature

So if you don’t have some excess CO2 in there, the shrinkage and absorption will tend to bring down headspace pressure. When I get to this point I typically hook up my regulator at 5-10 psi and leave it on until I package. At 35*F and 5 psi you’ll end up just over 2 volumes if you let it sit (same for 40*F at 7 psi), that’s my MO.

Someone can correct me if needed, but two things at play-

1. CO2 is more readily absorbed into the beer at lower temps

2. Volume shrinks a little when lowering temperature

So if you don’t have some excess CO2 in there, the shrinkage and absorption will tend to bring down headspace pressure. When I get to this point I typically hook up my regulator at 5-10 psi and leave it on until I package. At 35*F and 5 psi you’ll end up just over 2 volumes if you let it sit (same for 40*F at 7 psi), that’s my MO.

Without checking a carb table I think you have it right.

The carb table shows beer temp on one axis and PSI on the other axis. If you hold PSI steady and chill the beer more CO2 gets absorbed and this shows as increase volumes. I used to think the main drop was from gas shrinkage due to the ideal gas law but after more evaluation I think the increasing solubility of CO2 in beer as temp drops is the greater impact.

- Joined

- Feb 10, 2019

- Messages

- 160

- Reaction score

- 183

Without checking a carb table I think you have it right.

The carb table shows beer temp on one axis and PSI on the other axis. If you hold PSI steady and chill the beer more CO2 gets absorbed and this shows as increase volumes. I used to think the main drop was from gas shrinkage due to the ideal gas law but after more evaluation I think the increasing solubility of CO2 in beer as temp drops is the greater impact.

Someone previously corrected me about the same topic, so I’m regurgitating the information. My engineering background previously thought “shrinkage from temperature effect is the presiding factor”. Then someone brought up absorption and I went away with my tail between my legs- I hadn’t even considered that a factor.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I think your overthinking this. If you seal the fermentor at room temperature then cold crash to freezing a negative pressure will build and possibly damage your vessel. This can be avoided by connecting a co2 tank at .0001psi or more while cold crashing or just charging to 10ish psi prior to cold crashing. CheersSo does that mean pressure lessens as temperature drops? And if so, at what rate? At first I thought: to have positive pressure I'd need to make sure there was enough co2 in there to not be completely absorbed by the liquid in addition to it changing due to pressure drop. I feel like its better to just have co2 feeding into it at a certain pressure. If that is the case then what is the minimum it should be to make sure my baby doesn't get crushed.

- Joined

- Feb 10, 2019

- Messages

- 160

- Reaction score

- 183

I think your overthinking this. If you seal the fermentor at room temperature then cold crash to freezing a negative pressure will build and possibly damage your vessel. This can be avoided by connecting a co2 tank at .0001psi or more while cold crashing or just charging to 10ish psi prior to cold crashing. Cheers

Bingo- I shouldn’t have added more info than necessary, the idea is to prevent the pressure from going negative. In my original post I mentioned sucking in sanitizer or oxygen- by adding a source of co2, you allow that to go in instead. Remember whatever you set the regulator to is what pressure will be maintained. If you don’t actually want pressure, set it for 1 and leave it connected until terminal temperature (perhaps a little after).

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 14

- Views

- 1K

- Replies

- 3

- Views

- 817

- Replies

- 0

- Views

- 210

- Replies

- 41

- Views

- 2K

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)