- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

13 clogs later and finally done! I haven’t quite nailed my racking process for IPA’s just yet! I’m wondering if my 24hr cold crash isn’t long enough.

Hey all. Thought i would help add some insight. Just fwiw, anecdotal, etc. etc.

I have a cf5 with a 5.5% abv.

Have the neoprene jacket.

Cold crashing today.

Started at 9:30am, got to 36 at 1:10pm (4 hours).

Ambient temps close to 63 or so.

Glycol appc 33%, distilled h20 appx 66%.

Penguin 1/3 hp set to 28, with a 1 degree differinital.. (Standard differential setting).

Changed coil cool "in" at 39.1 (as per instruction manual).

Will let this stay at 36 for a bit... may try to push lower temp in a bit. Maybe say 32?

So... pretty super easy to get to 36 with ambient temps. If it was summet, my ac would be at may 78 or so.. give or take... so it may pick up more ambient heat. Ymmv.

It appears that you still have alot of solids looking at your sight glass. If you don't get all that out prior to racking your always going to have clogging. On the last 12 gallon batch I did I had close to 2 litres of solids before getting to clear beer. Cheers13 clogs later and finally done! I haven’t quite nailed my racking process for IPA’s just yet! I’m wondering if my 24hr cold crash isn’t long enough.

View attachment 654004

13 clogs later and finally done! I haven’t quite nailed my racking process for IPA’s just yet! I’m wondering if my 24hr cold crash isn’t long enough.

View attachment 654004

13 clogs later and finally done! I haven’t quite nailed my racking process for IPA’s just yet! I’m wondering if my 24hr cold crash isn’t long enough.

View attachment 654004

I have a suggestion for you. I used to use a jumper like this one connected to an OUT post as you have:

View attachment 654050

But then I tried something different. I put a camlock post on the fermenter and used this instead:

View attachment 654056

It's made a huge difference; much faster, and I haven't had it clog once since starting to use it. Part of it I think is that the tubing is larger than the 3/16" transfer jumper shown above, and partly because I don't have a poppet to clog on the upstream side.

View attachment 654054

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

How much dry hop in this batch? Sight glass looks like it’s all yeast so any dry hop must still be in the cone.

Also any reason to think the cam lock will work better than a 1/2” barb? I use lots of cam locks too but already bought the barb and used it first transfer.

I think the barb would work fine--the problem is stepping it down to connect to the quick disconnect. If you can't figure out a way to step it down, you might try this:

https://www.brewhardware.com/product_p/tc15hb38.htm

or this:

https://www.brewhardware.com/product_p/tc15hb14.htm

One reason I like the camlock connection--and you may have standardized on something else, or maybe don't use a pump--is that I can connect hoses from the pump or the counterflow chiller to the racking valve via the camlocks, and fill the fermenter through the racking valve/racking arm.

But there are lots of ways to skin this cat.

****

As far as the dry hop issue--I've done a couple IPAs with a fair amount of hops, but they settle below the racking arm. I typically use one of these:

View attachment 654062

to open up the QD and I flush the beer through it to clear the racking arm. It also has the added benefit of flushing the line of air, and I usually direct that beer into a small plastic pitcher which contents I then use to check final gravity.

Yea you can't really be stingy and use the conical as designed imho. My advise is make 1 extra gallon than your planning to package and don't feel bad dumping it. You will end up with a cleaner end product and you won't have a bunch of sediment in your serving keg. CheersI guess the clogs are a result of being stingy loosing beer and trying to dump minimal yeast/hops. I only dumped maybe 1/2 liter at most. What you see in the sight glass is 4oz of hops. After I finally finished racking it was evident I needed to remove more of the hop debris and crash longer than 18hours. I had the racking cane at 3 o’clock position.

Still learning how to package these hoppy beers. I mostly brew Darker stuff.

13 clogs later and finally done! I haven’t quite nailed my racking process for IPA’s just yet! I’m wondering if my 24hr cold crash isn’t long enough.

24 hours Probably is on the short side. We crash our hazys for several days at work and dump the cone day 2 and before transfer. At home and on our pilot system I don't bother with dumps from the bottom but I do dump the racking port. I dont use the racking arm. I crash to 40 (what my chiller allows) let it sit a day or two then dump the racking port till clear, it doesn't take much.

I highly recommend using the beer bouncer or the knock of version ($15) in line between your port and the ball lock I have run 40 or so batches of fruited and heavily hopped beer through it and it works excellent. I simply hook my assembly up to my liquid side and purge with the co2 in the keg before hooking up.

When I read the email, I thought of you in this thread and the backlash you received from others.Note from Spike in my mailbox today, RE using PRV for spunding purposes:

Dear Brewmasters,

Thank you for your past purchase of a Spike gas manifold, we certainly appreciate your business!

We’ve recently noticed some customers commenting and using the gas manifold as a spunding valve during pressure fermenting. A spunding valve is used to release pressure at a pre-designated pressure level, set by the brewer. The Spike gas manifold, however, was not engineered to be used in the same fashion as a spunding valve. Instead, it was engineered to be a safety pressure release during forced carbonation and pressure transfers.

Using the Spike gas manifold to pressure ferment during primary fermentation can lead to unsafe conditions. When we refer to pressure fermentation we mean adding wort to your conical, pitching yeast, and then sealing off the fermenter with the Spike gas manifold instead of a pressure blow-off (e.g., an airlock, a blow-off tube, etc.). During primary fermentation, the krausen can slowly rise filling the lid head space. If the Spike gas manifold is used instead of a pressure blow-off, the krausen can fill the gas manifold and clog the safety pressure release valve. With the safety pressure release valve clogged and the fermentation reaction creating additional pressure with nowhere to go, eventually a failure can occur that can result in a substantial mess, and potentially an injury.

For these reasons, we do not recommend that you use the Spike gas manifold to ferment under pressure (i.e. during primary fermentation). We at Spike are continuing to investigate reliable and safe options for pressure fermentation. When we identify such an option, we will let you know.

If you have any questions, please reach out to our service team at [email protected]

Thanks,

Team Spike

Well, shoot. That was one of the reasons I bought the Spike, so I could essentially do spunding.

I'm going to have to think about this. I don't let the PRV act as a spunding valve, I wait until there's about 7 or so points of gravity remaining and then seal up the fermenter.

One thing I may look into is using my 1.5" sight glass under the PRV so I could see if the krausen is approaching the top. I mostly do 5-gallon brews in my CF10 so I think this is a non-issue in those cases, but with a vigorous fermentation and a too-full fermenter, I can see how the krausen would invade the pressure manifold.

I suppose, too, that I could just have a blowoff barb or cane on there and when I get to the 7 points or so of gravity remaining, simply quickly swap the blowoff barb for the pressure manifold. It would admit almost no air to do that, and with the fermentation still ongoing, that oxygen should be used up.

Thoughts on all this?

Note from Spike in my mailbox today, RE using PRV for spunding purposes:

Dear Brewmasters,

Thank you for your past purchase of a Spike gas manifold, we certainly appreciate your business!

We’ve recently noticed some customers commenting and using the gas manifold as a spunding valve during pressure fermenting. A spunding valve is used to release pressure at a pre-designated pressure level, set by the brewer. The Spike gas manifold, however, was not engineered to be used in the same fashion as a spunding valve. Instead, it was engineered to be a safety pressure release during forced carbonation and pressure transfers.

Using the Spike gas manifold to pressure ferment during primary fermentation can lead to unsafe conditions. When we refer to pressure fermentation we mean adding wort to your conical, pitching yeast, and then sealing off the fermenter with the Spike gas manifold instead of a pressure blow-off (e.g., an airlock, a blow-off tube, etc.). During primary fermentation, the krausen can slowly rise filling the lid head space. If the Spike gas manifold is used instead of a pressure blow-off, the krausen can fill the gas manifold and clog the safety pressure release valve. With the safety pressure release valve clogged and the fermentation reaction creating additional pressure with nowhere to go, eventually a failure can occur that can result in a substantial mess, and potentially an injury.

For these reasons, we do not recommend that you use the Spike gas manifold to ferment under pressure (i.e. during primary fermentation). We at Spike are continuing to investigate reliable and safe options for pressure fermentation. When we identify such an option, we will let you know.

If you have any questions, please reach out to our service team at [email protected]

Thanks,

Team Spike

Well, shoot. That was one of the reasons I bought the Spike, so I could essentially do spunding.

I'm going to have to think about this. I don't let the PRV act as a spunding valve, I wait until there's about 7 or so points of gravity remaining and then seal up the fermenter.

One thing I may look into is using my 1.5" sight glass under the PRV so I could see if the krausen is approaching the top. I mostly do 5-gallon brews in my CF10 so I think this is a non-issue in those cases, but with a vigorous fermentation and a too-full fermenter, I can see how the krausen would invade the pressure manifold.

I suppose, too, that I could just have a blowoff barb or cane on there and when I get to the 7 points or so of gravity remaining, simply quickly swap the blowoff barb for the pressure manifold. It would admit almost no air to do that, and with the fermentation still ongoing, that oxygen should be used up.

Thoughts on all this?

I do the same. CheersI, like Sbe2 start with the blowoff barb, then add the manifold when the primary fermentation starts to subside and the krausen drops. I was concerned with krausen contaminating the pressure gage, PRV, or gas port so never started fermentation with the manifold. I add dry hops when I install the manifold and purge with CO2 to reduce the exposure to oxygen.

If the krausen gets into your spunding valve and prv valve you can over pressurize the vessel. Theres no real way around it and it's the same for all conicals regardless of who made them. I guess if you bought one planning to seal it all the way thru and for whatever reason didn't know that's a possibility it's a bummer. CheersWhat's wrong with spunding off the gas manifold?

I highly recommend using the beer bouncer or the knock of version ($15) in line between your port and the ball lock I have run 40 or so batches of fruited and heavily hopped beer through it and it works excellent. I simply hook my assembly up to my liquid side and purge with the co2 in the keg before hooking up.

When I read the email, I thought of you in this thread and the backlash you received from others.

I start with the blowoff barb then switch to the manifold when I DH with a few points left. I add the manifold first, connect it to gas and pump 2-3 psi of CO2 while I dry hop. I then purge and continue on my way until I am ready to rack.

I have never fermented under pressure so I can’t offer any insights, but I would think that Krausen would not be able to rise as much due to the head pressure created above the beer. Also, you could add fermcap to reduce the krausen.

I don't recall any statement to that effect from Spike but anyway they're just saying that the gas manifold is unsuitable for spunding or pressure fermentation, not the fermenter itself.Honestly I think this post from Spike is total BS bait and switch. These tanks were sold to ferment under pressure now clarification that’s not what we meant?

Hey all. Thought i would help add some insight. Just fwiw, anecdotal, etc. etc.

I have a cf5 with a 5.5% abv.

Have the neoprene jacket.

Cold crashing today.

Started at 9:30am, got to 36 at 1:10pm (4 hours).

Ambient temps close to 63 or so.

Glycol appc 33%, distilled h20 appx 66%.

Penguin 1/3 hp set to 28, with a 1 degree differinital.. (Standard differential setting).

Changed coil cool "in" at 39.1 (as per instruction manual).

Will let this stay at 36 for a bit... may try to push lower temp in a bit. Maybe say 32?

So... pretty super easy to get to 36 with ambient temps. If it was summet, my ac would be at may 78 or so.. give or take... so it may pick up more ambient heat. Ymmv.

I dont know exactly what the total area is for headspace but usually it's about 2.5 gallons of headspace , then the lid is domed which helps give it extra space. Have anyone using the spike fermenters seen any krausen markings get up the the lid?

Note from Spike in my mailbox today, RE using PRV for spunding purposes:

Dear Brewmasters,

Thank you for your past purchase of a Spike gas manifold, we certainly appreciate your business!

We’ve recently noticed some customers commenting and using the gas manifold as a spunding valve during pressure fermenting. A spunding valve is used to release pressure at a pre-designated pressure level, set by the brewer. The Spike gas manifold, however, was not engineered to be used in the same fashion as a spunding valve. Instead, it was engineered to be a safety pressure release during forced carbonation and pressure transfers.

Using the Spike gas manifold to pressure ferment during primary fermentation can lead to unsafe conditions. When we refer to pressure fermentation we mean adding wort to your conical, pitching yeast, and then sealing off the fermenter with the Spike gas manifold instead of a pressure blow-off (e.g., an airlock, a blow-off tube, etc.). During primary fermentation, the krausen can slowly rise filling the lid head space. If the Spike gas manifold is used instead of a pressure blow-off, the krausen can fill the gas manifold and clog the safety pressure release valve. With the safety pressure release valve clogged and the fermentation reaction creating additional pressure with nowhere to go, eventually a failure can occur that can result in a substantial mess, and potentially an injury.

For these reasons, we do not recommend that you use the Spike gas manifold to ferment under pressure (i.e. during primary fermentation). We at Spike are continuing to investigate reliable and safe options for pressure fermentation. When we identify such an option, we will let you know.

If you have any questions, please reach out to our service team at [email protected]

Thanks,

Team Spike

Well, shoot. That was one of the reasons I bought the Spike, so I could essentially do spunding.

I'm going to have to think about this. I don't let the PRV act as a spunding valve, I wait until there's about 7 or so points of gravity remaining and then seal up the fermenter.

One thing I may look into is using my 1.5" sight glass under the PRV so I could see if the krausen is approaching the top. I mostly do 5-gallon brews in my CF10 so I think this is a non-issue in those cases, but with a vigorous fermentation and a too-full fermenter, I can see how the krausen would invade the pressure manifold.

I suppose, too, that I could just have a blowoff barb or cane on there and when I get to the 7 points or so of gravity remaining, simply quickly swap the blowoff barb for the pressure manifold. It would admit almost no air to do that, and with the fermentation still ongoing, that oxygen should be used up.

Thoughts on all this?

Spike website is dump yeast, cold crash, then force carbonate). I pulled that sample and had a big uh oh reaction but am sure it is going to be fine.

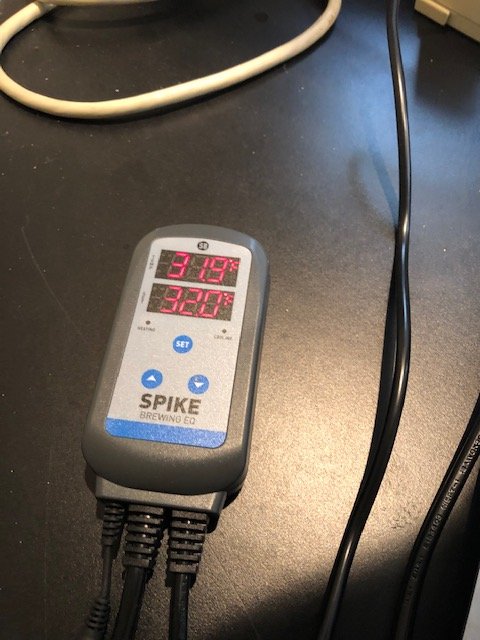

Were you able to get to 32F? I was able to get to 31.9F....

CF10 with a 7.2% ABV

Neoprene jacket

Ambient temp 69F

Fermentation temp 72F

Glycol 25% / RO 75%

Icemaster 100 -5.5c, with a 1 degree differential

Used coil "in" for less than 40F

View attachment 654231

Ok, also- on the Spike PRV email...

I read it as "dont use our pressure manifold to spund with. Use it IN ADDITION to a Spunding Valve".

Maybe i missed that?

Also- say i get a pro-grade 1.5" tri clamp Spunding valve and put it on where the pressure manifold goes. Doesnt that also run the risk of a clog?

I think this is why the pros must have a tee (or a seperate prv) for spunding?

Hi All,

I've been considering a CF or Flex+. This thread has been amazingly informative and helpful (but I'm still suffering from paralysis by analysis!). The ideas and methods here are genius!

But wanted to let you know that a bunch of stuff (including all CFs, but NOT the Flex) is in the Bargain Cave on the Spike website. Looks to be about 6% off. Not sure if this is their Black Friday deal(s) or not.

Is the beer carbed when you are running it through the bouncer?

I know the spike prv topic buried this, but I also was interested in your answer about using this on carbed beer. I never considered using it as I figured it will be a foamy mess trying to keg carbed beer through it.

Thanks.

No the CF is not on black friday sale. They always have various 'scratch n dent' in the bargain cave.

The spike flex and flex+ is going on sale.

You can go to high gravity brew and get a discoint on gify cards (i think 10%?) And then use them to get the discount flex or flex+.

However... i would stringly consider a cf model. More money but imo a much better deal.

Also consider how you will handle temp control. A flex might fight easier in a dorm fridge. Big savings. A cf will.almost certainly need an upright fridge/freezer OR a temp control package. That is more money.

Just to throw MORE info at you! Lol

With LA3 I have had it blow off into my starsan using the hose barb TC. I fill to 6 gallons when doing a NEIPA. So it can happen. I have never used the gas manifold for the entire fermentation.I dont know exactly what the total area is for headspace but usually it's about 2.5 gallons of headspace , then the lid is domed which helps give it extra space. Have anyone using the spike fermenters seen any krausen markings get up the the lid?

It appears that you still have alot of solids looking at your sight glass. If you don't get all that out prior to racking your always going to have clogging. On the last 12 gallon batch I did I had close to 2 litres of solids before getting to clear beer. Cheers