OEHokie

Well-Known Member

ScubaSteve's build was definitely an inspiration: https://www.homebrewtalk.com/f11/single-vessel-all-electric-ns-nc-brewery-158608/ Mine is basically going to be the bastardized mini-version of his that won't look as good.

My brew process is going to be basically the same. I've ordered a 36 quart stainless steel stockpot w/steamer basket. I'm going to line the steamer basket with SS mesh and use this as my first all-grain setup.

At the bottom of the pot I'm going to have two 1500W Extra low density heating elements running off of two separate 120V/20A breakers in my kitchen (I live in an apartment). Also at the bottom will be the SS dip tube and temperature probe.

I've ordered the BCS-460 to control my heating elements and pump. I picked it over the brewtroller because of the better integration with the internet.

Since I want to brew very small... ~1.5 gallon batches... there's an issue with the deadspace at the bottom. The pot diameter is 13.5" which means that every inch takes 2.5 quarts. I'm going to put something in the bottom (don't know what yet, open to suggestions) that will displace enough water, so more of it overlaps the basket.

What else... the control box. Not sure what I'm going to do with this yet. I did like the toolbox version done here: https://www.homebrewtalk.com/f51/simple-brewing-est-2009-build-147021/ So, I may give that a shot. The march pump won't be in the box. One of the 120V connections is going to power one of the heating elements, while the other is going to power the second heating element, march pump and bcs-460. When I do the micro-batches I might not need both elements. I'm going to have covered toggle switches for both heating elements that can cut the power (overriding the BCS). The outlets in my kitchen aren't GFCI, so I'll have that inside the box too. I will also have 3+ SSRs (one for each heating element and one for the march pump, and for the solenoid valves if I get those).

Question: Is that how most people (in the automated setups) control their march-pump (100% on or off)... or is there a better solution to provide variable power, using the BCS?

Question: When recirculating, how do I get all the fluid back into the kettle? The march pump won't be able to push it out once it gets past the pump, correct?

I'm going to have a CFC to cool down the wort (I really liked ScubaSteve's all copper one, so I might look into making one of those too).

It's not going to have a permanent stand... though I do have a kitchen cart that I will be using most of the time.

Equipment list:

Next, I'm going to reserve some spots on here for pictures later.

I'm a little weak on electrical knowledge, so any pointers are welcome.

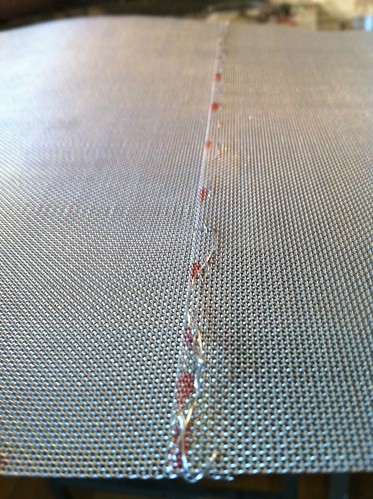

My brew process is going to be basically the same. I've ordered a 36 quart stainless steel stockpot w/steamer basket. I'm going to line the steamer basket with SS mesh and use this as my first all-grain setup.

At the bottom of the pot I'm going to have two 1500W Extra low density heating elements running off of two separate 120V/20A breakers in my kitchen (I live in an apartment). Also at the bottom will be the SS dip tube and temperature probe.

I've ordered the BCS-460 to control my heating elements and pump. I picked it over the brewtroller because of the better integration with the internet.

Since I want to brew very small... ~1.5 gallon batches... there's an issue with the deadspace at the bottom. The pot diameter is 13.5" which means that every inch takes 2.5 quarts. I'm going to put something in the bottom (don't know what yet, open to suggestions) that will displace enough water, so more of it overlaps the basket.

What else... the control box. Not sure what I'm going to do with this yet. I did like the toolbox version done here: https://www.homebrewtalk.com/f51/simple-brewing-est-2009-build-147021/ So, I may give that a shot. The march pump won't be in the box. One of the 120V connections is going to power one of the heating elements, while the other is going to power the second heating element, march pump and bcs-460. When I do the micro-batches I might not need both elements. I'm going to have covered toggle switches for both heating elements that can cut the power (overriding the BCS). The outlets in my kitchen aren't GFCI, so I'll have that inside the box too. I will also have 3+ SSRs (one for each heating element and one for the march pump, and for the solenoid valves if I get those).

Question: Is that how most people (in the automated setups) control their march-pump (100% on or off)... or is there a better solution to provide variable power, using the BCS?

Question: When recirculating, how do I get all the fluid back into the kettle? The march pump won't be able to push it out once it gets past the pump, correct?

I'm going to have a CFC to cool down the wort (I really liked ScubaSteve's all copper one, so I might look into making one of those too).

It's not going to have a permanent stand... though I do have a kitchen cart that I will be using most of the time.

Equipment list:

- Six 2 gallon jugs for mini-fermenters (in possession)

- 36 Quart Stockpot (ordered, ~$100 (amazon))

- BCS-460 w/temperature probe (4") and SS fittings (ordered, $~225)

- March Pump (ordered ~$110 (ebay))

- 2x 1500W Extra Low Density Heating Elements ($50, plumbing supply. Thanks Harkin)

- 10x 120V 25A SSRs ($30, ebay... have extra if anyone is interested)

- Valves (waiting)

- SS Mesh (ordered, mcmaster)

- chillzilla (ordered, $110, eBay!)

Next, I'm going to reserve some spots on here for pictures later.

I'm a little weak on electrical knowledge, so any pointers are welcome.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)