Cutting out the ice/water dispenser was not too difficult, I just used a small cut off wheel and trimmed the plastic covering on the inside so that the door would be flush in that area. Initially I was going to take out the entire plastic door panel and replace it with dryerase board or plastic but I decided to keep the factory shelves othe door so that I had extra space for mugs, bottles or brewing supplies. I can easily get 3 cornies ithe freezer side without changing the factory shelving but I might weld or build something out of wood to get a fourth in there.

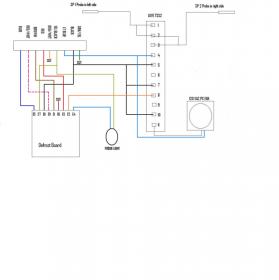

The PC fan is installed directly in the wall and the output side is almost the size of the entire fan so I can exchange a large volume of air and get the right side temps down fairly low. If you look at the design of the right side and how air is exchanged you may not have a good flow if you have the original two exchange holes and another for the pc fan, that's why I installed my fan directly in place of the damper exchange. I also have the fridge wired so that the evaporator fan kicks in with the pc fan, this should create a good flow of warmer air from the right side to come up through the bottom of the right side and be chilled as it moves up and back out the top.

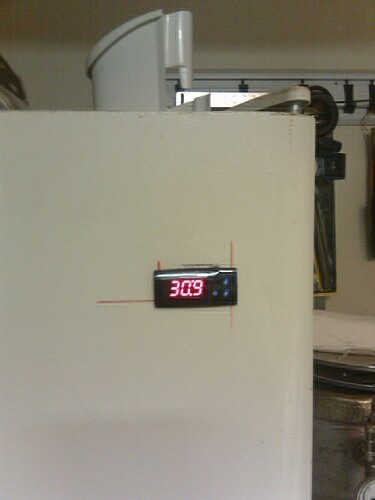

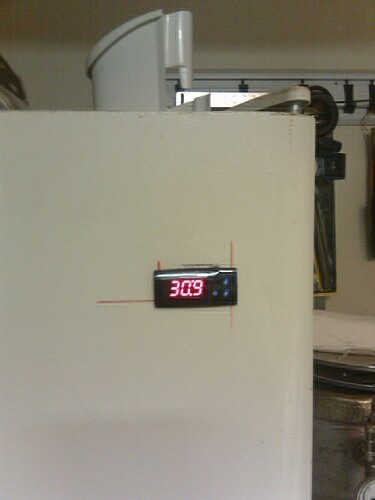

Before installing the fan I couldnt get the right below about 52 F and without a warming source I couldnt get it but a few degrees warmer than the set temp. Right now I have a lager fermenting in the right side so I haven't played with the temps much more but initially I had the left at 38 F and the right at 65 F with no problem. Currenlty I have the left at 38 and the right at 48 with a lager fermenting. Oh and by the way I would guess that my garage is routinely 120 F.

I had planned on installing a louvered dryer vent flush with the fan to prevent air from exchanging on it's own but it seems to be working as is so im not really that concerned with doing this quite yet.

I hope that answered all your questions. I am really confident in how this is working and if anyone needs help, feel free to ask.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)