r8rphan

Well-Known Member

Where are you guys getting these fancy Blue LED Volt/Amp DROs?

Where are you guys getting these fancy Blue LED Volt/Amp DROs?

![20160226_170349[1].jpg 20160226_170349[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301852-20160226-170349-1-.jpg)

![20160430_124626[1].jpg 20160430_124626[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301853-20160430-124626-1-.jpg)

![20160504_133842[1].jpg 20160504_133842[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301854-20160504-133842-1-.jpg)

![20160504_133906[1].jpg 20160504_133906[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301855-20160504-133906-1-.jpg)

![20160504_133914[1].jpg 20160504_133914[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301856-20160504-133914-1-.jpg)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

The panel hasn't changed, only the wall its mounted to in the brew room. Air brushed lightning bolts have been added, and Arguably, this has improved the beer production by 8.5 %.

Wall is awesome. But I love how the focal point of the brewery is the pool table. Is that a Brunswick Gold Crown? What year?

Its a 10' snooker table, not a pool table. Big difference. Its actually a Gandy big G, built in Georgia in the '70s. The company went out of business years ago. Similar to the Gold Crown in design, but more heavy duty.

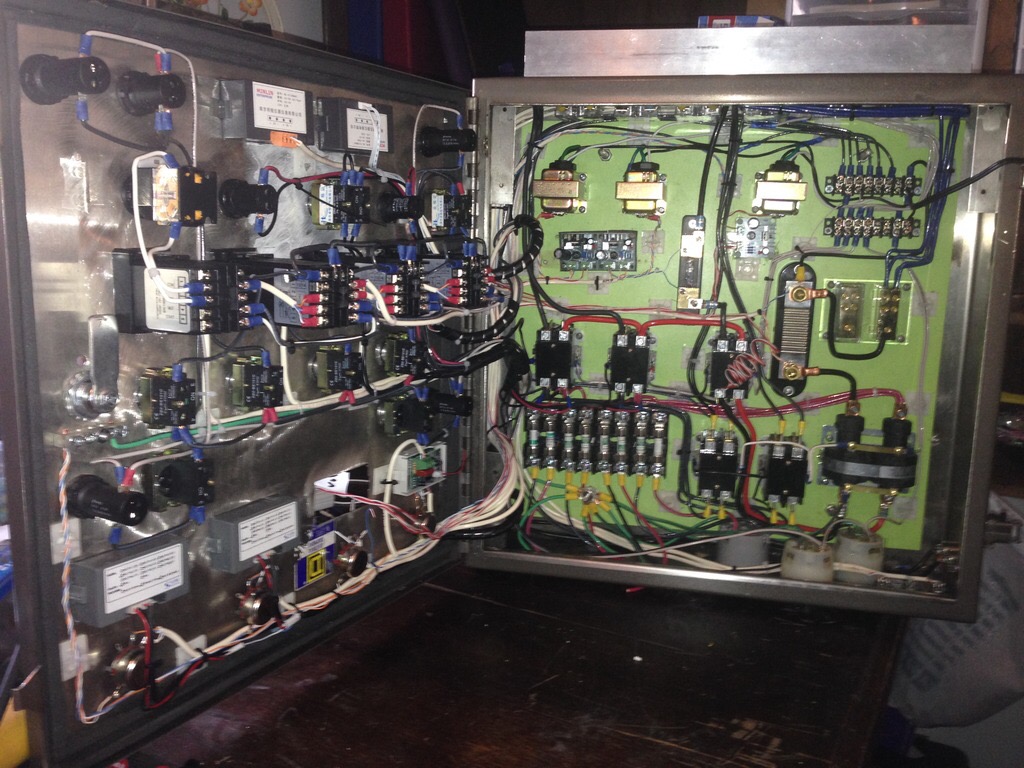

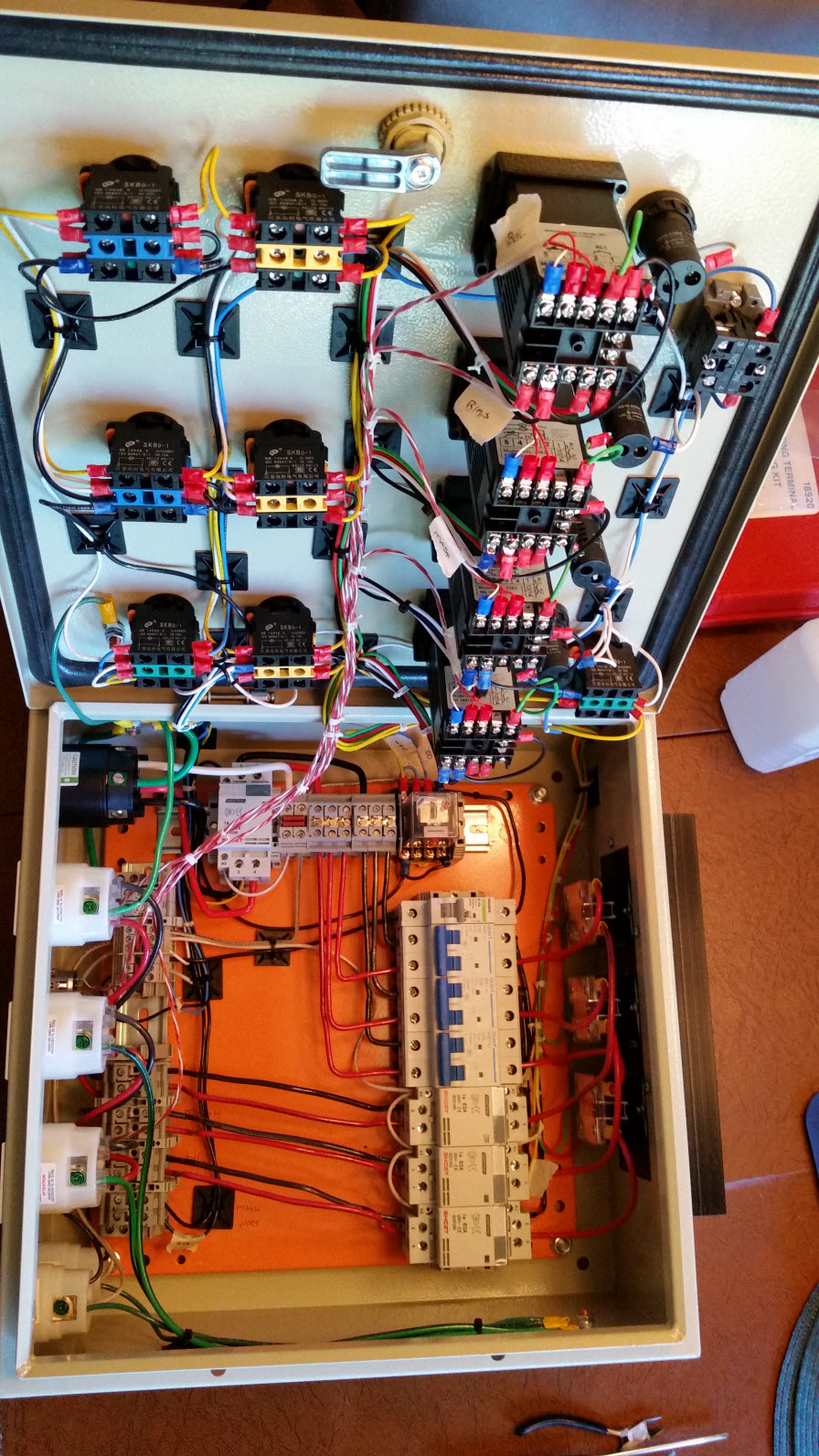

My updated panel. 3phase, 400v/16A (I live in Sweden, so the electric system differs from U.S)

3 SSR with quite small heatsinks, but 2 fans makes sure that they stay cool.

Dual outlet, one for HLT and one for the boiler. The on/on switch is used to choose if the PID or the "boil controller" triggers the SSRs.

Indivual Volt/Amp meters (one per phase)

You're one of the few people that turned the enclosure hinge horizontal. I was wondering why more people don't do this. I'm about to ouch holes in my build. I currently will only be running two PIDs, but if I wanted to add another it seems it would be easier since I can leave more space between them.

Just makes it slightly harder since you have to hold it open anytime you're in there.

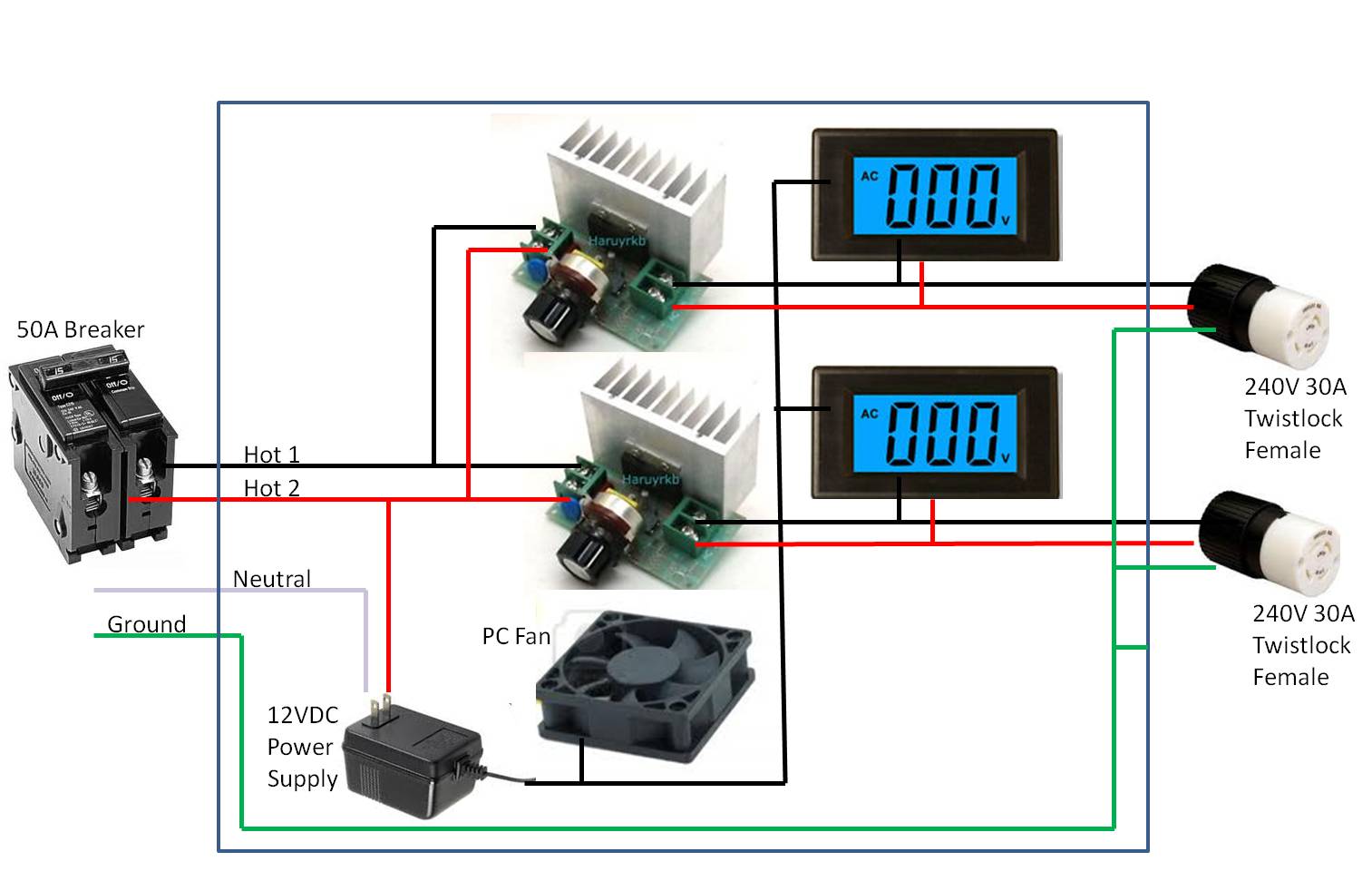

I call it Megatron. My double duty 50amp electric chair/beer brewer.

I'm building a dual purpose controller for an "electric chair" too. [emoji78] What are all the pots on the bottom for? They look like analog voltage regulator controls, but that doesn't make sense since you've got the PIDs. I'm lost, but also impressed. Love your build.

What about if the hinge was on the bottom?

Just make sure your wiring lengths are good to your front panel so when It swings down it doesn't rip any wires loose.

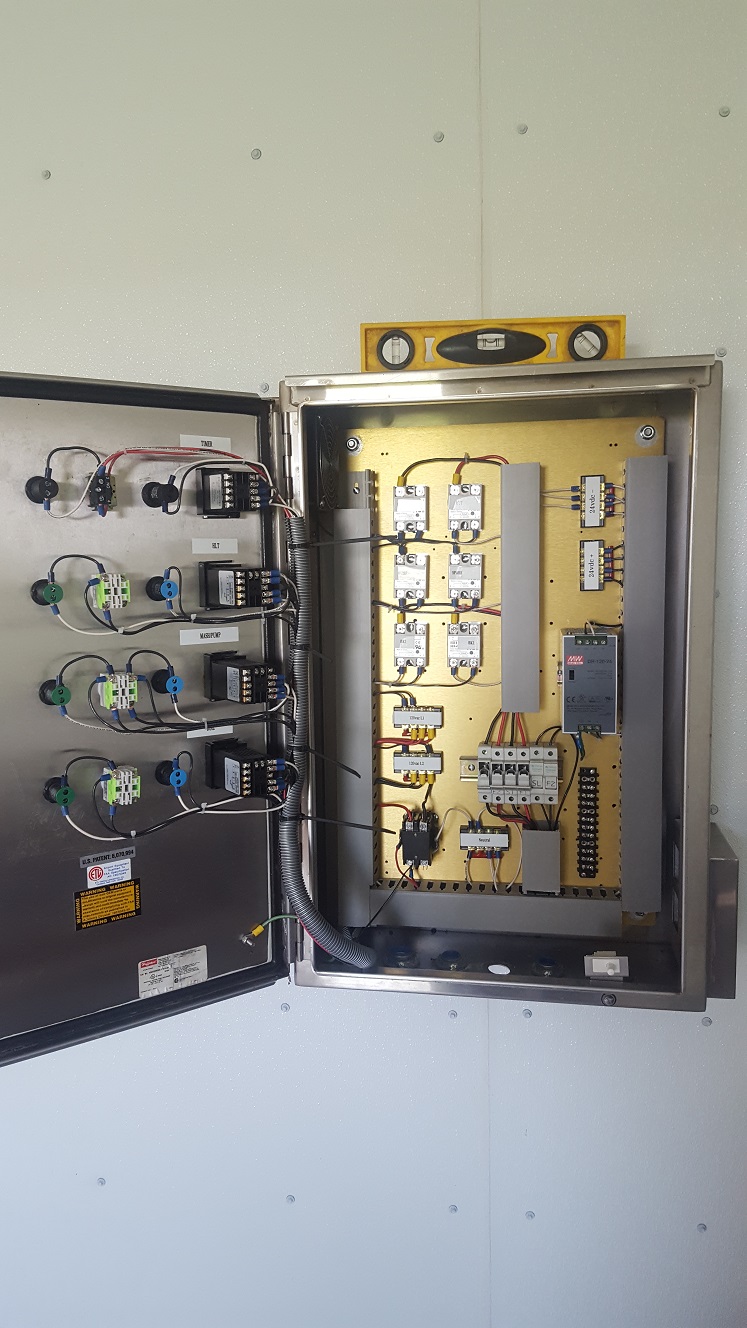

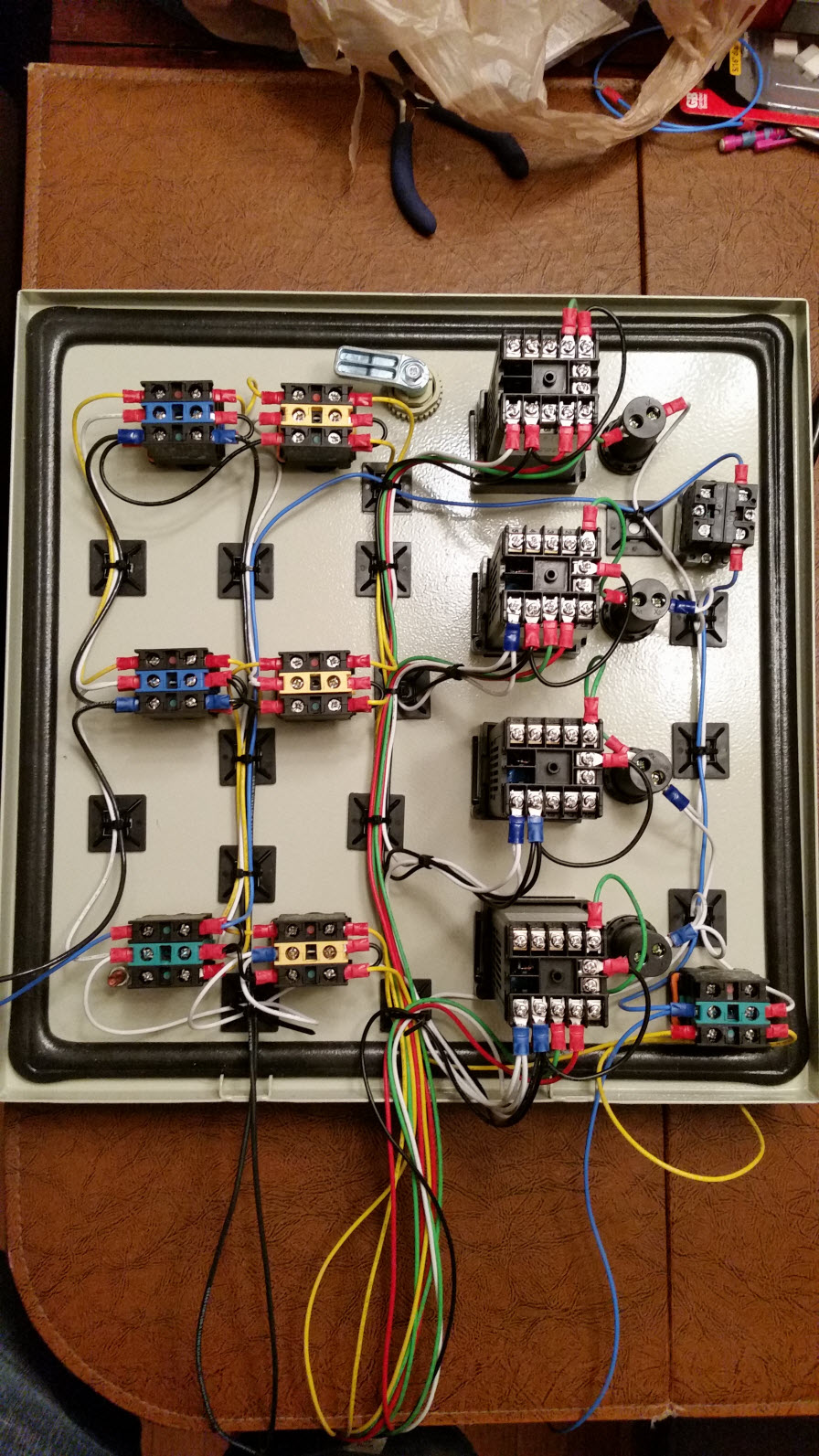

I am about 95% finished with my panel. Waiting on wire for the temp sensors. I built a brewery in my pump house. I will do a full write up on it after I get it up and running. Hoping to have the first brew in it next weekend.

I am about 95% finished with my panel. Waiting on wire for the temp sensors. I built a brewery in my pump house. I will do a full write up on it after I get it up and running. Hoping to have the first brew in it next .

That sticker looks pretty sweet.

I am about 95% finished with my panel. Waiting on wire for the temp sensors. I built a brewery in my pump house. I will do a full write up on it after I get it up and running. Hoping to have the first brew in it next weekend.

Are you planning on heatsinks for the SSR. I mounted this giant heatsink and it was barely warm after one hour of 2 elements running.