wilserbrewer

BIAB Expert Tailor

Are those 2 heatsticks ?

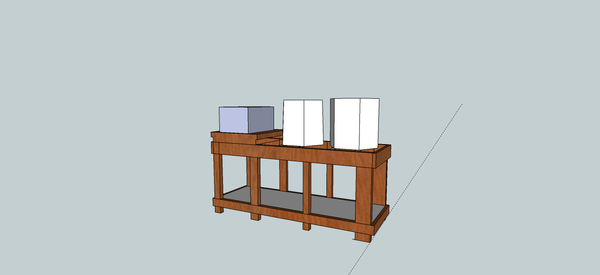

Yep...2 heat sticks at 2000w each. I have also removed the third tier, and have simply chosen to transfer the sparge water w/ the one gallon pitcher, I actually find it easier and faster than gravity draining the HLT.

Here is my present configuration...as you can see, I can't pass up a good deal on a brewpot...hah.

11 gal stainless bayou classic from costco...$23 with ss burner

15 gal alum w/ lid...$43 shipped

20 gal alum w/ lid...$25 c'list

20 gal heavy stainless...$50 c'list

edit...hah...that's where all the ping pong balls are.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)