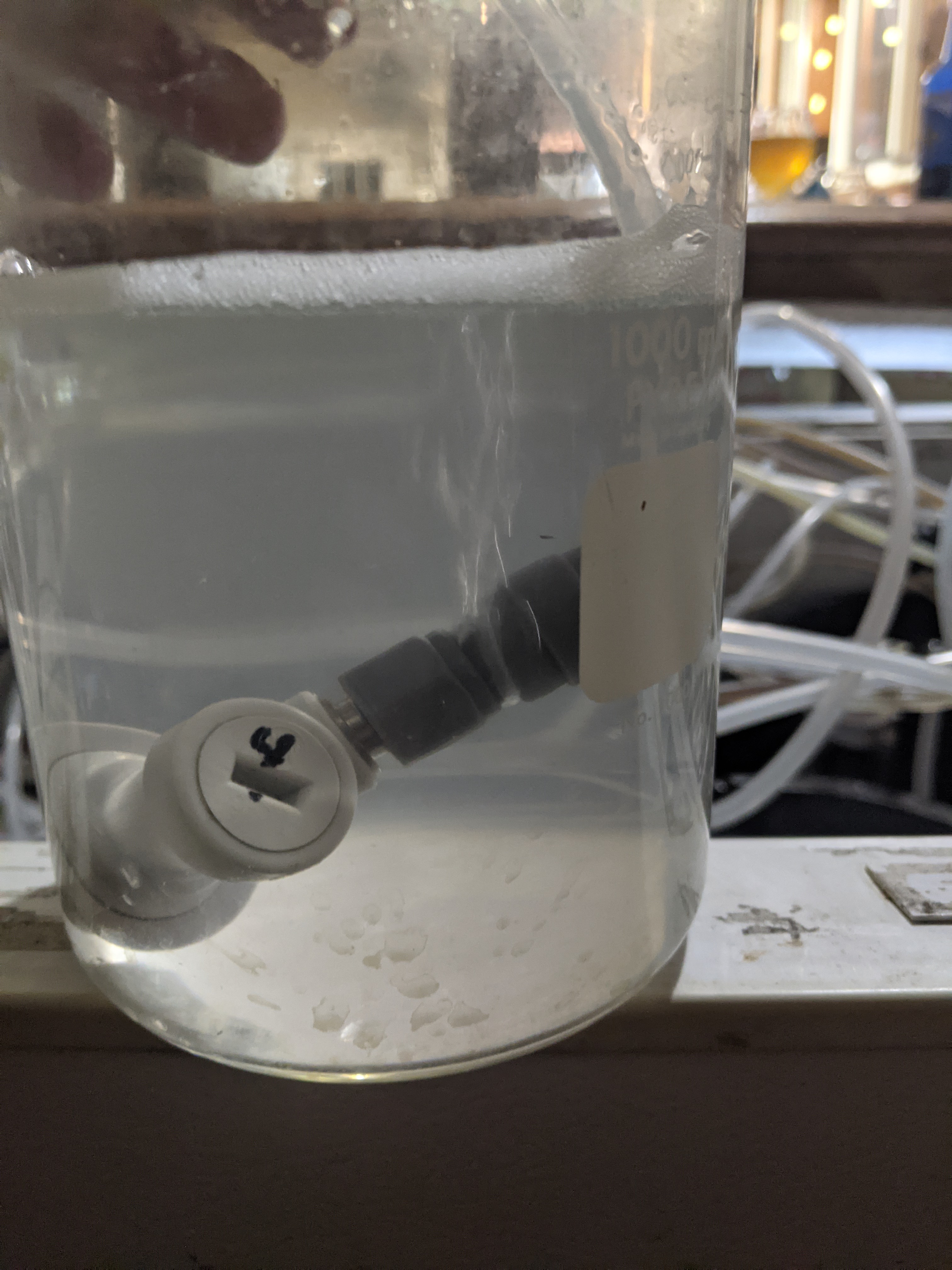

I bought 39ft of Eva barrier 4mmID tubing and it won't fit over the barbs. So I was thinking about returning it and exchanging for the 6mm but then I started looking at the duo tight fittings which will work with 5/16th OD lines. So I'm wondering, should I try to return the lines or should I just keep the 4mm and order the duotight fittings. Hoping to spread this 39 ft between 4 kegs if possible. Hoping 10 ft for each keg would be enough. Currently running about 13psi

What do you guys think?

What do you guys think?