...or should I just replace the gauges on the one I already have?

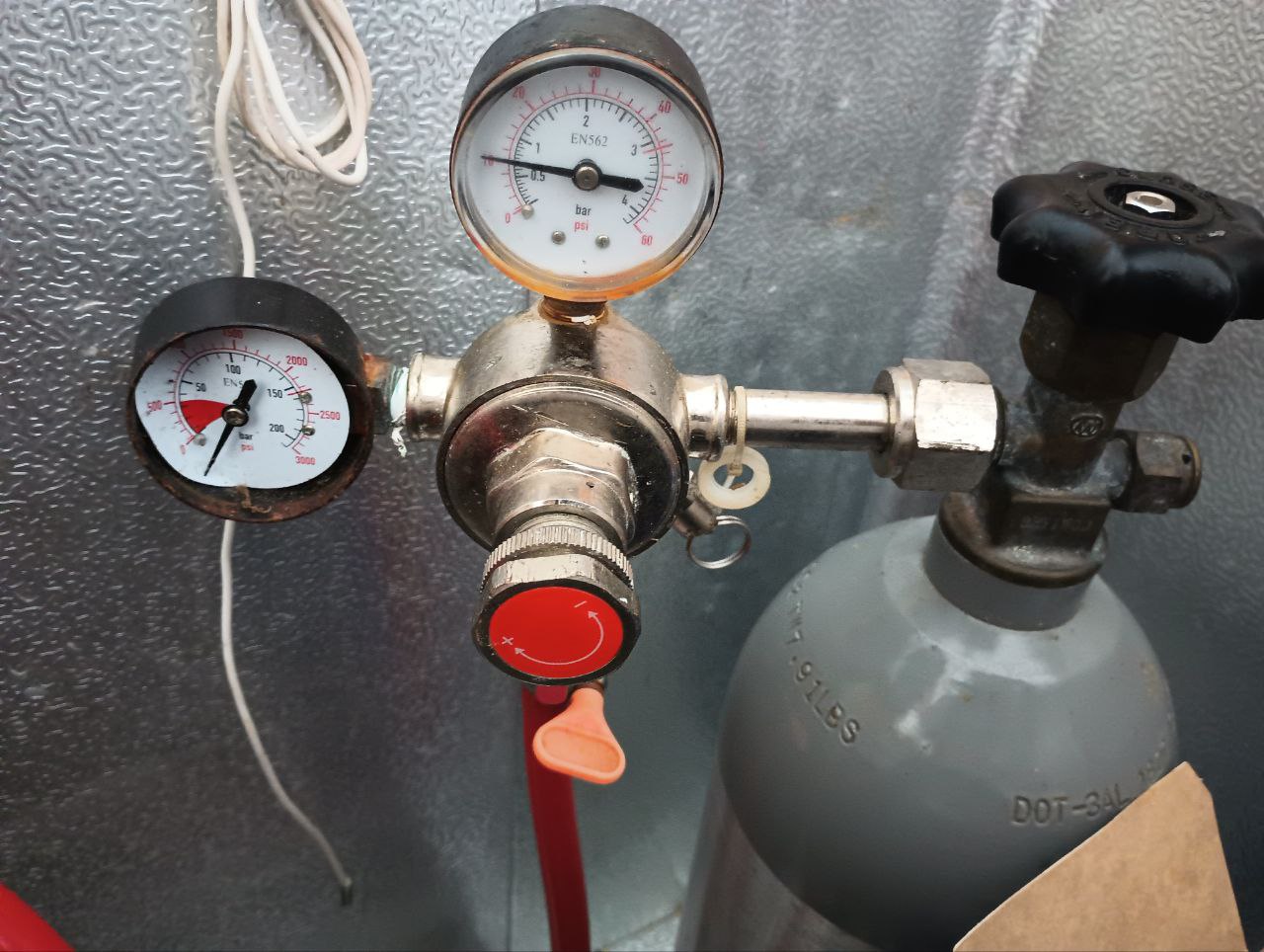

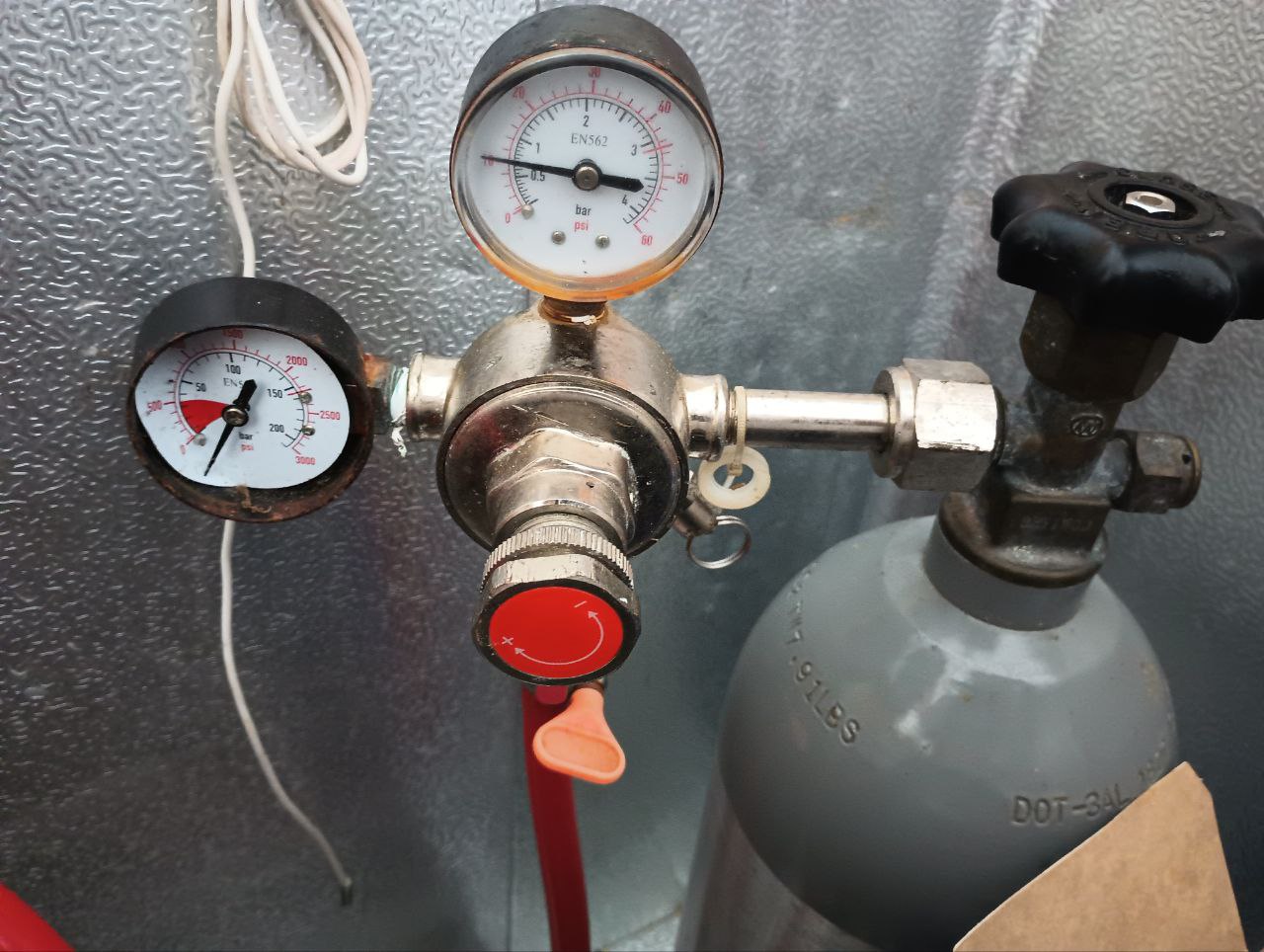

Assuming that broken high pressure gauge is the only problem, you can just replace the gauge. Or you could replace it with a plug. The high pressure gauge in a CO2 regulator is of limited value.

On a side note, how does one check for leaks?, spray bottle and starsan?

Do you suspect that you have a leak? You can use starsan solution or soapy water and look for bubbles. But first, I'd pressurize the system to, say, 30 PSI, shut off the gas at the cylinder, let it sit for a while, then check the (low pressure) gauge, to see if it has moved. If it has, then there is a leak. Next, repeat the test, but also close the regulator's own shutoff valve (assuming it has one) as well as the main cylinder after pressurizing. This time, if the gauge hasn't moved after the wait, that means the leak is downstream from the regulator (or at the regulator to hose connection). Otherwise, it's the regulator itself (or the regulator's connection to the CO2 cylinder).

I've always seemed to have way to much flow and have been needing to barely crack the handle for the beer to flow at an acceptable rate.

The faucet should be pulled fully open. If not, you'll get a lot of foam. If the beer is flowing too fast when the faucet is wide open, the system is unbalanced, and you need to balance it. Balancing the system should be done in this order...

- Determine the average temperature inside the fridge.

- Decide how many volumes of CO2 you want

- Using a keg carbonation chart, find the PSI needed to maintain the CO2 level you chose, given the temperature

- Given the PSI from the previous step, determine the length of beer line you need to balance the system, so that the beer exits the faucet fast enough for a reasonably fast pour, without excessive foaming. There are calculators that can help with this last step.