I'm trying to wrap my head around switches and am getting more confused than anything. I finally understand the difference between NO and NC, and somewhat understand the differences between SPST/SPDT/DPST/DPDT. But what I don't understand is the reason for having 1 Contact Block vs 2 Blocks.

To simplify, how are these 2 Selector switches different and why and when would you want a second block.

2 Way Selector 1 NO contact

http://www.ebrewsupply.com/2-way-1-no-contact-switch/

2 Way Selector 2 NO contacts

http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=241

Pretty much I'm looking for a simple ON/OFF selector switch to control power to the actual control panel and 2 more for my pumps.

And secondly, how do selector switches vary from a simple rocker switch? I see the selector switches have Contact Blocks and a rocker does not, do they function the same?

I will also need 3 way switches for the automation of my HLT burner with AUTO/OFF/ON options.

What is the main difference between these 2 switches

3 WAY Selector with 2 NO Contacts

http://www.ebrewsupply.com/3-way-2-no-contact-switch/

3 WAY SPDT Rocker switch

https://www.radioshack.com/products/spdt-6amp-switch

To simplify, how are these 2 Selector switches different and why and when would you want a second block.

2 Way Selector 1 NO contact

http://www.ebrewsupply.com/2-way-1-no-contact-switch/

2 Way Selector 2 NO contacts

http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=241

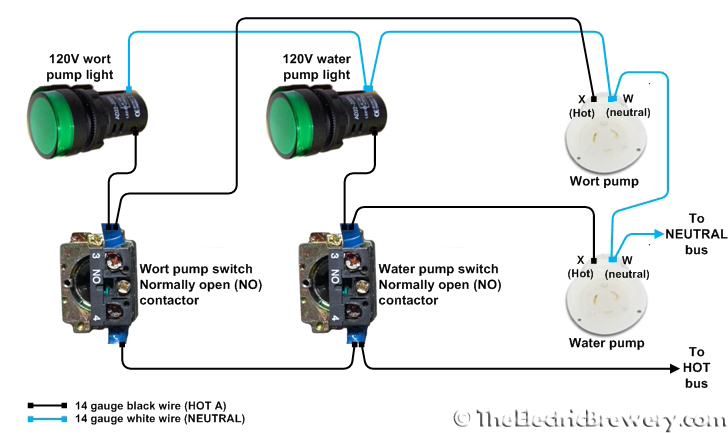

Pretty much I'm looking for a simple ON/OFF selector switch to control power to the actual control panel and 2 more for my pumps.

And secondly, how do selector switches vary from a simple rocker switch? I see the selector switches have Contact Blocks and a rocker does not, do they function the same?

I will also need 3 way switches for the automation of my HLT burner with AUTO/OFF/ON options.

What is the main difference between these 2 switches

3 WAY Selector with 2 NO Contacts

http://www.ebrewsupply.com/3-way-2-no-contact-switch/

3 WAY SPDT Rocker switch

https://www.radioshack.com/products/spdt-6amp-switch

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)