I have the same general brew set up. The RIMS tube from Brewhardware.com is absolutely awesome. I have interlocked my system set up so that my RIMS element can't fire without the pump being tuned on. Handy for all those times I've turned off the pump and momentarily forgotten the RIMS! I also use SCR voltage regulators for an even more gentle heating. Much simpler to use than PID's.

I don't know if you use your RIMS and pump to aid in heating your strike water or if it is also used to help bring your wort to boil, but in my system the RIMS and Pump stay connected throughout each step of the brew day. The CFC is added inline the last 15 minutes of the boil. Think of the "RIMS/Pump/CFC system" as having an input and an output which are moved between the different kettle ports for the different steps of your brew day. You own it so might as well use it to the fullest.

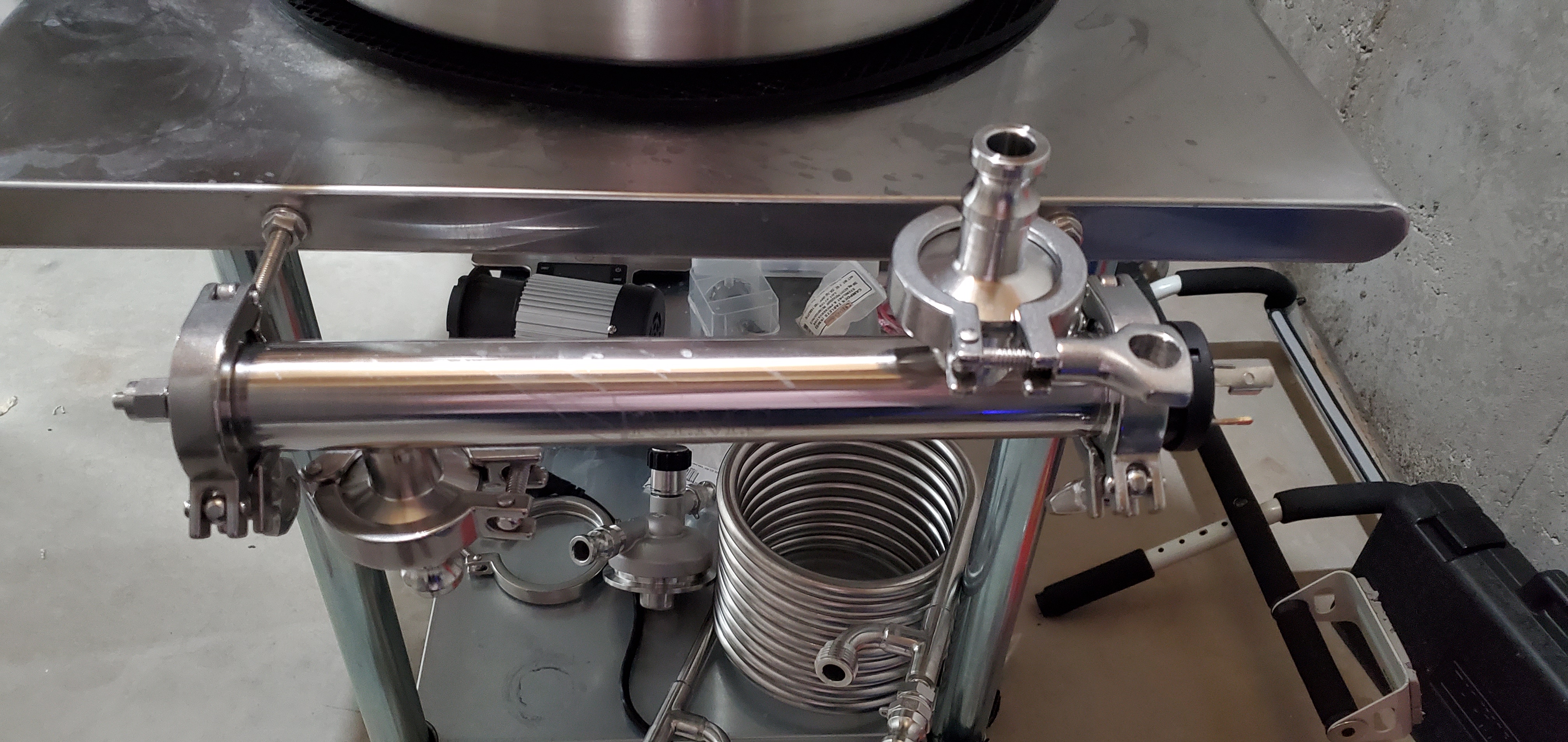

Another benefit of using the RIMS/Pump continuously (not the first 75 minutes of the boil of course) is the temperature probes can be mounted on the inlet and outlet of the RIMS tube which negates the need for probes on the kettles! Picture attached for clarity, silicone tubes no shown. Also note the flow meter which opens a whole slew of additional control and checks.

View attachment 711272

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)