I'm looking at RO being my next big "consistency" step as my city water varies wildly season to season. And short of buying a (rather pricey) test kit so I can see what's coming out of the tap TODAY, I'm at best, guessing at what I'm starting with.

I'm in Virginia Beach, VA. I brew in my unheated garage, so I have to worry about freezeup. For my biggest brew days, I need about 20-25 gallons (10 gallons finished, 14 into Fermentor.

The storage tanks get pretty expensive in the size range I'd need to let the RO run and have water when I need it relative to the cost of the system.

Anyone have it set up where maybe the night before, you have it start flowing into the HLT and MLT (jumpered together)

I was thinking this

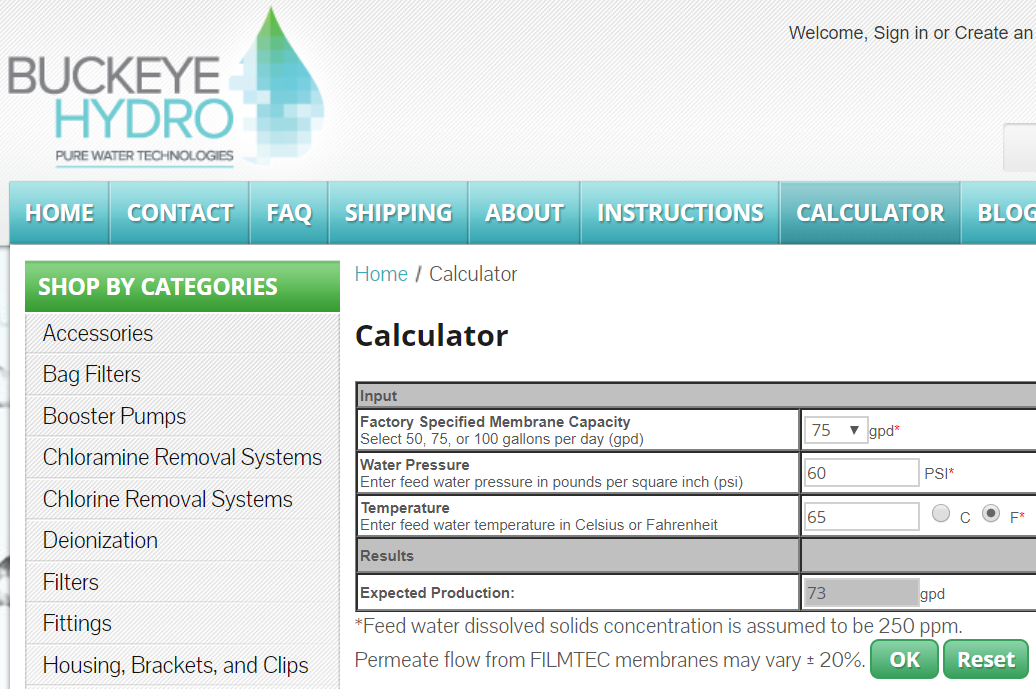

http://www.buckeyehydro.com/auto-shut-off-valve-kit/ installed to shut off an inch or so below the to of my HLT, (MLT is taller) and have it start collecting water the day before.

Three main concerns:

1- Can that valve handle being exposed to the temps in a HLT (175ish to get the MLT to 170F for mash out, it's a HERMS system)

2-Since there's no disinfectant in the water, how long can it sit before things grow? MLT and HLT would have lids on but not airtight. Biggest concern is there's always a little residue in the MLT that escaped cleaning. I'd hate to come out in the morning and BAM funky water.

3-HLT is Aluminum. Any corrosion issues with RO and older aluminum pot? It's eventually going to get upgraded to SS, but that's a "when it breaks or I have $400 burning a hole in my pocket" upgrade.

To mitigate freezeup and membrane getting da funk from not being used for weeks, I was thinking of getting a smaller undersink tank and a RO Faucet in the kitchen and just move it to the garage for brew days, with appropriate valving installed for being able to turn 3 valves off, and popping off the John Guest style fittings and walking out the garage with it, and putting it in it's home there, hook up inlet, outlet to the tank valve, and the brine drain lines, purge a quart, and then leave it running.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)