I've been looking into upgrading my RO system as the under sink unit really isn't practical when it comes to the volumes required for brewing, and the unit I have springs a new leak every time I replace the ceiling tile below it so the whole operation is getting moved to the basement so now is the time to do it. I have very hard, occassionally smelly well water. About a year ago added a whole house filtration unit that consists of a a 5 micron filter, a KDF85 filter, and a carbon filter. The output of this is fed to the water softener. Water is fine from a taste and odor perspective after this treatment. My under sink unit has a sediment filter and two carbon filters before the membrane. In my mind I can eliminate these as the water has already been sufficiently filtered and is naturally chlorine free and plumb the softened water straight the the membrane. Before I go ahead a trash a perfectly good membrane I'm hoping someone with a little more expertise on the subject will chime in a reassure me the plan is sound.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RO Membrane Question

- Thread starter MI_Troll

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I was going to say that the whole house carbon filter wasn't capable of removing all the chlorinated compounds since they are typically run at too high a flow rate. However, your well water probably is not chlorinated. So that concern is moot.

So in your case, it may be quite feasible to feed the membrane directly from the softener without prefilters. However, I would still keep a 1 micron particulate filter in place to protect the membrane from the stray particle. I think you should be able to go years before the particulate filter would need to be replaced since there are no penalties for having a somewhat clogged filter. Its flow capability is still going to be much higher than what the membrane unit will allow.

So in your case, it may be quite feasible to feed the membrane directly from the softener without prefilters. However, I would still keep a 1 micron particulate filter in place to protect the membrane from the stray particle. I think you should be able to go years before the particulate filter would need to be replaced since there are no penalties for having a somewhat clogged filter. Its flow capability is still going to be much higher than what the membrane unit will allow.

What's the concern with leaving them in place? I run through a Vortex, big pressure tank (lots of opportunity for particulates to settle) and softener before the water reaches my RO system which contains wound and carbon filters. These have shown no increase in pressure across them in 5 years of operation which shouldn't be a surprise considering all the 'filtration' before they are reached. I guess I could take them out and not replace them but it never occurred to me to do that. Extra insurance against mustiness?

GotPushrods

Well-Known Member

The main reason I thought to remove them was maintenance costs. I suppose if they aren't really doing anything they should last a really long time so the cost to maintain approaches nil. Thanks for the feedback.

I agree with the previous posters; it's added insurance and they'll last a long time. No reason to get rid of them.

I would recommend a simple set of tubing cutters. (Like these) It will probably run you 10-20 bucks, and are worth their weight in gold. Getting a clean cut on 1/4" tube will give you a great seal with John Guest fittings. It was hard for me to stomach the idea of John Guest at first, but I've never had a drip since getting a clean cut....the unit I have springs a new leak every time I replace the ceiling tile below it

Two points here.I've been looking into upgrading my RO system as the under sink unit really isn't practical when it comes to the volumes required for brewing

1. You can always install a float valve (like this one) on a large NSF plastic water barrel or trash bin. You can let your reservoir fill as slowly as you need.

2. If you're set on upgrading, I'd recommend the Dow Filmtec 75 gpd membrane. Don't forget to pair it with the appropriate flow restrictor for the waste water. 550 ml/min is perfect. If you know your silica is low, you can get away with restricting it a bit more and increasing your recovery slightly.

I don't remember where I saw them, but you can get pre-tested 99% (?) rejection guaranteed membranes for around 30-40 bucks. These are the best residential membranes I've used. I regularly get 99% rejection in the summer and 98.5% in the winter at 65 psi input and 25% recovery. This is from ~500 TDS water. With warm input water and good pressure, you can easily get >100 gpd from this membrane.

Last edited by a moderator:

It was hard for me to stomach the idea of John Guest at first, but I've never had a drip since getting a clean cut.

Interesting comment. I too found them a little disquieting until I found them in my RO system at 150 psig. I guess the higher the pressure the more firmly the tube is pressed into the teeth and the tighter the seal. I've never had a drip from one either and now have them all over the brewery/lab.

BuckeyeFS

Member

Use a 5 micron, or better yet a 1 micron sediment filter. IF your carbon tank is working correctly, you won't need an additional carbon prefilter.

Sanitize your system every other filter change or about once a year.

Russ

Sanitize your system every other filter change or about once a year.

Russ

BuckeyeFS

Member

Even quick connect fittings eventually leak - especially if the tubing is routes so there is lateral stress. The orings in the fittings need to be replaced periodically (think years).

If you know your silica is low, you can get away with restricting it a bit more and increasing your recovery slightly.

I've been running recovery at about 33% because of what I consider to be high silica (28 mg/L) because it is at the upper edge of the range typically found in ground water in the US and the dealer from whom I bought the system mumbled something about being concerned about high silica. I've had the same set of membranes for at least 5 yrs now and no problems yet. Is this consistent with your concept/experience RE 'low' silica?

GotPushrods

Well-Known Member

ajdelange said:I've been running recovery at about 33% because of what I consider to be high silica (28 mg/L) because it is at the upper edge of the range typically found in ground water in the US and the dealer from whom I bought the system mumbled something about being concerned about high silica. I've had the same set of membranes for at least 5 yrs now and no problems yet. Is this consistent with your concept/experience RE 'low' silica?

You know, I don't have any particular number, and I don't try to bump my recovery. I was told this by a family member (and a completely unrelated in-law) who both work for water utilities that this is the case. I should press further since I have never given the actual threshold a second thought. The 28 mg/L is the first I've heard someone quote a hard number. I'd be curious to find some hard facts about it. I might be tempted to play with recovery rates, although living on a bed of sand doesn't bode well.

BuckeyeFS

Member

Although silica can foul a membrane, it's not where I'd focus. A more common concern is hardness. Just as hardness forms scale on your plumbing fixures, it will scale the inside of a membrane. This is why we put softeners in front of many commercial RO units. Especially with well water, iron, manganese, and hydrogen sulfide are also common issues. We just worked with a microbrewery who has high manganese in his city water that had been fouling his membranes.

Russ

Russ

BuckeyeFS

Member

You're not likely going to find a "max silica number" as the solubility varies with pH and temperature. If you've been using the same membranes for 5 years, it doesn't look like silica is an issue to be too concerned with, at least at your current recovery.

Russ

Russ

Temperature, yes, pH, no, at least not to any appreciable extent in typical water. The first pK of silicic acid is about 9.8 so as long as water pH is below, say, 7.8, which mine is, it can be considered fully protonated.

The number I threw out was not given as a maximum but rather as the upper end of the typical range. It is recognized that some supplies would contain more than 30 mg/L.

If you do limiting salt analysis calcium carbonate almost always wins and does indeed limit recovery. This is why the under sink units typically have recoveries lower than 20%. As a consequence of that the majority of RO units are, or should be, fed with softened water and mine is. Thus silicate becomes more important as there isn't much you can do about it. My water softener does take out a little and as I don't see how that could happen chemically I assume it is just gumming up the resin beads and has potential to gum up the RO membranes.

In any case I don't need higher recovery. Thirty three percent is OK.

The number I threw out was not given as a maximum but rather as the upper end of the typical range. It is recognized that some supplies would contain more than 30 mg/L.

If you do limiting salt analysis calcium carbonate almost always wins and does indeed limit recovery. This is why the under sink units typically have recoveries lower than 20%. As a consequence of that the majority of RO units are, or should be, fed with softened water and mine is. Thus silicate becomes more important as there isn't much you can do about it. My water softener does take out a little and as I don't see how that could happen chemically I assume it is just gumming up the resin beads and has potential to gum up the RO membranes.

In any case I don't need higher recovery. Thirty three percent is OK.

No, its probably not gumming up the softener beads. Silicate has to be at a higher concentration to scale. That concentration does occur in the boundary layer along the membrane face, however the degree of concentration is directly influenced by the starting concentration.

As Russ mentions, silicate is not typically the primary driver for the degree of bulk flow in most water supplies. But there are places where the water supply has high silicate and it does end up as the defining ion. The big problem with silicate is that the precipitate is virtually impossible to remove chemically and that means once you have scaled silicate on the membrane, its trash. That is not the case for calcium scale which can be removed with strong acid treatment.

As Russ mentions, silicate is not typically the primary driver for the degree of bulk flow in most water supplies. But there are places where the water supply has high silicate and it does end up as the defining ion. The big problem with silicate is that the precipitate is virtually impossible to remove chemically and that means once you have scaled silicate on the membrane, its trash. That is not the case for calcium scale which can be removed with strong acid treatment.

No, its probably not gumming up the softener beads. Silicate has to be at a higher concentration to scale.

I agree that it shouldn't be depositing but then that silica has to be going somewhere. Could be assay error I guess as the input/output numbers are not widely different. Probably also worth noting that quartz (pKs = 3.7) is less soluble than amorphous silica (pKs = 2.7).

No, as I noted in my previous post, it is usually a calcium or magnesium salt but a softener takes care of those. Assuming my softener gets each of Ca and Mg down to 2 ppm as CaCO3 and using a polarization factor of 1.15 (for no better reason than that I've seen that number in example calculations) my recovery limits are all above 90% with respect to the common salts with the exception of silica for which it is 44%. So silica is my limiting 'salt'.As Russ mentions, silicate is not typically the primary driver for the degree of bulk flow in most water supplies.

Chez moi is one of them. I could tolerate a polarization factor of up to 1.35 before I limit at 33% recovery and so feel comfortable operating the system at that level rather than 50% which I can easily achieve but I don't pay for water so I don't really care what my recovery is.But there are places where the water supply has high silicate and it does end up as the defining ion.

Perhaps more interesting in terms of this discussion is the observation that if my softened water contained 15 mg/L silica it would still be the limiting salt for me but max allowable recovery would go up to 60%. Based on this I'll throw out the thought that as many, probably the majority of RO installation require a softener that silica may indeed be the limiting salt for the majority of users. This thought merges with gotpushrod's statement that his contacts had told him he could push recovery beyond 25% if his silicate were low.

The big problem with silicate is that the precipitate is virtually impossible to remove chemically and that means once you have scaled silicate on the membrane, its trash. That is not the case for calcium scale which can be removed with strong acid treatment.

As I don't have a problem with either after 5 years I'm assuming even though natural waters typically exhibit 1 - 30 mg/L silica content and I'm at the upper end of that range that 33% recovery is adequately low to prevent deposition. I was worried about this but it seems it's not a problem at least for me. That's why I was interested in what silica levels other people may have to deal with and how they operate their systems.

- Joined

- Dec 17, 2013

- Messages

- 806

- Reaction score

- 345

...my recovery limits are all above 90% with respect to the common salts with the exception of silica for which it is 44%. So silica is my limiting 'salt'.

Do you mean "rejection" rather than recovery? Two entirely different things.

Russ

Do you mean "rejection" rather than recovery? Two entirely different things.

Russ

...my recovery limits are all above 90% with respect to the common salts with the exception of silica for which it is 44%. So silica is my limiting 'salt'.

Do you mean "rejection" rather than recovery? Two entirely different things.

No, I meant "recovery limits" i.e. the maximum level of recovery that is possible before the salt under consideration becomes saturated at the membrane. The more of any ion in the water the lower the recovery must be (the more dilute the concentrate) in order to prevent deposition. The 'limiting salt' is the one that requires the lowest recovery, in the case under discussion here silica, and it is that 'salt' that limits how high I can set the recovery in my system. Were it not for the silica I could run at much higher recovery than I do (not that I would).

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Buckeye, didn't realize you were the one and the same Buckeye I just ordered a booster pump from!

Got a question or two for you, if you don't mind.

I have a 75 GPD RO system that I'm in the process of moving/upgrading. The system is currently equipped with an aquatec ERP-1000 permeate pump and a 4 gallon tank. I'm installing an aquatec 8800 booster pump and a 10+ gallon tank, primarily to provide water for brewing but also providing drinking water via a spigot at the kitchen sink and water/ice for a refrigerator.

First question, can I keep the permeate pump in place? From the research I've done, it shouldn't be an issue and should still help with water usage.

Second question, the system currently has an 800ml inline restrictor with an integrated flush valve. I had debated adding in an auto-flush restrictor, and I'm wondering if I should use a lower flow restrictor.

Got a question or two for you, if you don't mind.

I have a 75 GPD RO system that I'm in the process of moving/upgrading. The system is currently equipped with an aquatec ERP-1000 permeate pump and a 4 gallon tank. I'm installing an aquatec 8800 booster pump and a 10+ gallon tank, primarily to provide water for brewing but also providing drinking water via a spigot at the kitchen sink and water/ice for a refrigerator.

First question, can I keep the permeate pump in place? From the research I've done, it shouldn't be an issue and should still help with water usage.

Second question, the system currently has an 800ml inline restrictor with an integrated flush valve. I had debated adding in an auto-flush restrictor, and I'm wondering if I should use a lower flow restrictor.

- Joined

- Dec 17, 2013

- Messages

- 806

- Reaction score

- 345

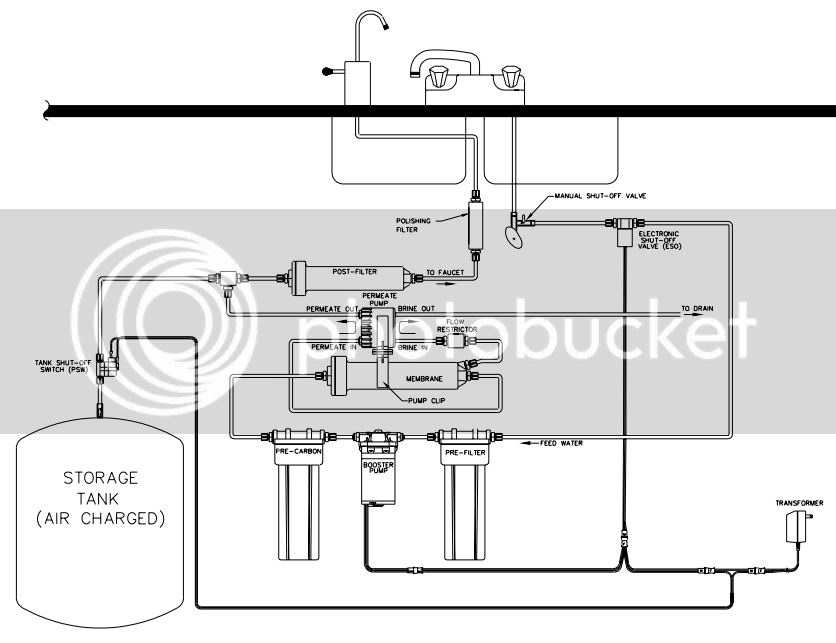

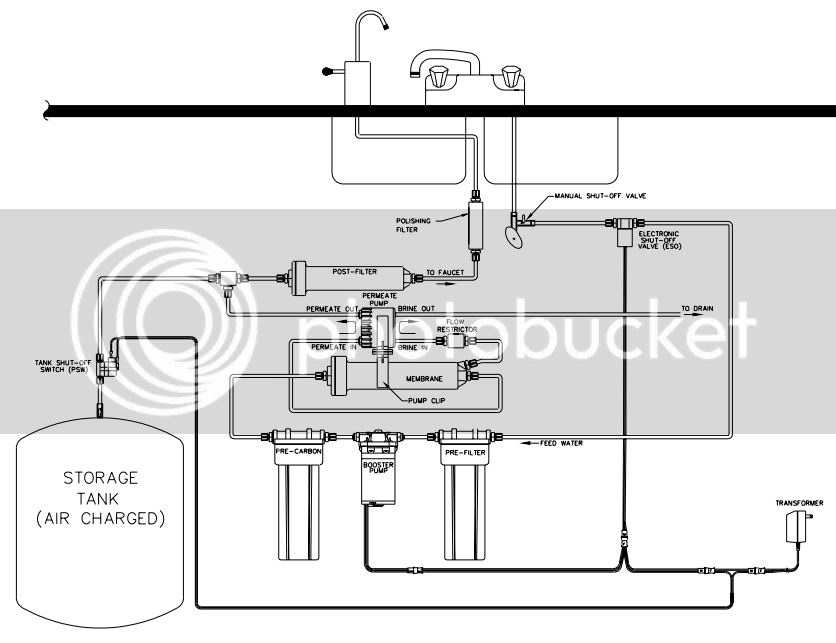

No problem with using a permeate pump with a booster pump - you'll get the benefits of both. Here's one way to hook it up (I'd put a small strainer and then the pump after the carbon block, rather than how it's shown here:

A couple of comments about your flow restrictor:

Do you have the kind with the little black handle that open/closes the flush? If so, over the years we've seen problems with that family of restrictors and you might want to invest a few $ in a different one.

An 800 flow restrictor is probably not giving you what you want. Assuming you have 60 psi and 77F water, the 800 is intended for a 100 gpd membrane.

There are autoflush valves with, or without, an integrated flow restrictor. we recommend you put a wye in the waste water line, and one one leg install an appropriate capillary style flow restrictor. On the other leg install an auto flush valve without a integrated flow restrictor. You can bring both legs back together with another wye fitting. Some vendors sell this type of configuration pre-assembled.

Russ

A couple of comments about your flow restrictor:

Do you have the kind with the little black handle that open/closes the flush? If so, over the years we've seen problems with that family of restrictors and you might want to invest a few $ in a different one.

An 800 flow restrictor is probably not giving you what you want. Assuming you have 60 psi and 77F water, the 800 is intended for a 100 gpd membrane.

There are autoflush valves with, or without, an integrated flow restrictor. we recommend you put a wye in the waste water line, and one one leg install an appropriate capillary style flow restrictor. On the other leg install an auto flush valve without a integrated flow restrictor. You can bring both legs back together with another wye fitting. Some vendors sell this type of configuration pre-assembled.

Russ

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Ok, thanks for the tips. Just ordered a shut off solenoid from you. Wish I had read this post first, would have ordered the restrictor setup as well!

Booster pump is set up to deliver 80 psi, water is out of a well so it's a bit cold these days. Temp is about 53-55 degrees right at the pump entrance.

The flush valve is the one with the black handle. What kind of problems have there been?

Edit: Decided to call directly. Thanks for the help and the advice.

Buckeye Hydro is a great guy to do business with!

Booster pump is set up to deliver 80 psi, water is out of a well so it's a bit cold these days. Temp is about 53-55 degrees right at the pump entrance.

The flush valve is the one with the black handle. What kind of problems have there been?

Edit: Decided to call directly. Thanks for the help and the advice.

Buckeye Hydro is a great guy to do business with!

Similar threads

- Replies

- 32

- Views

- 4K