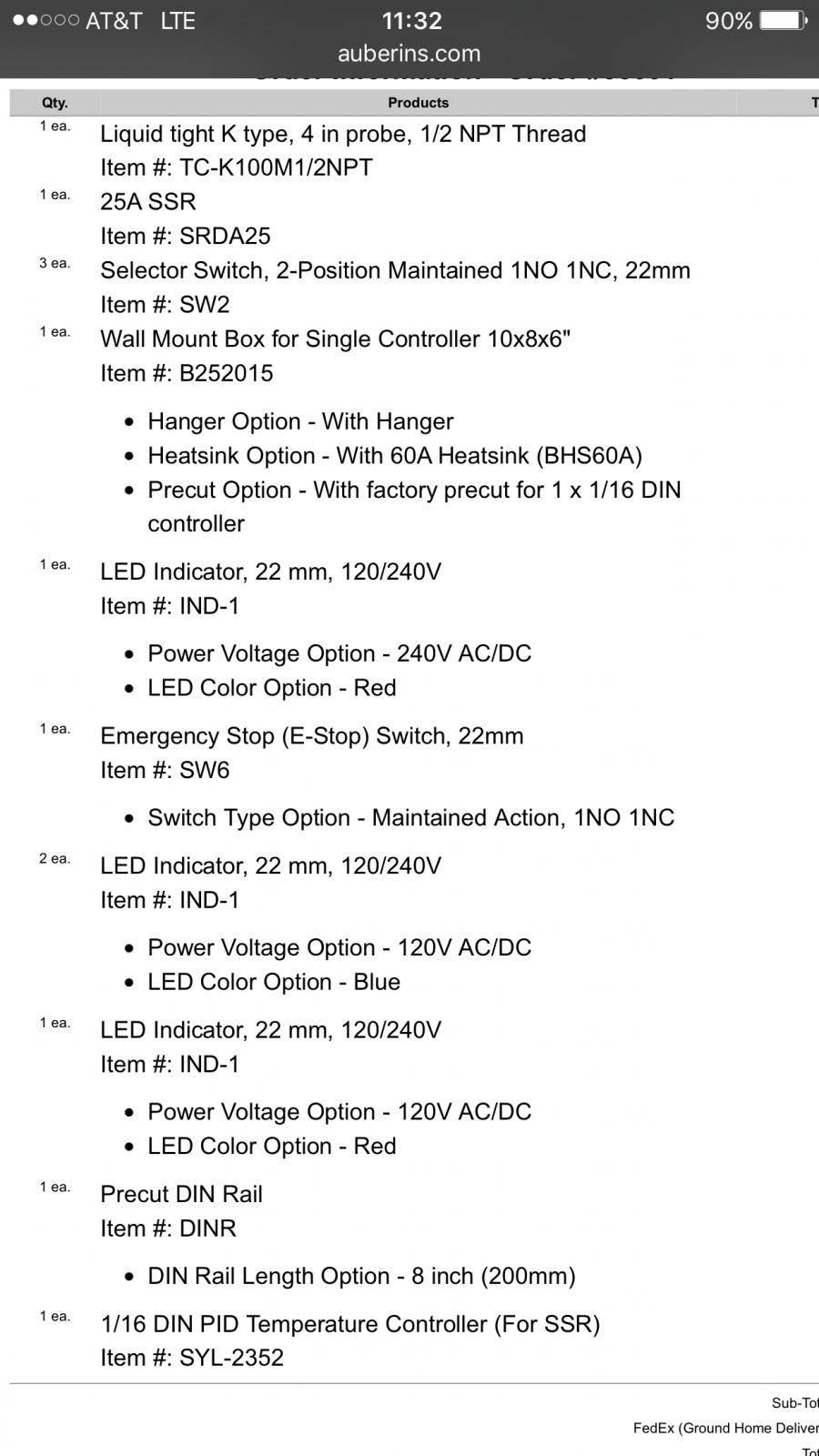

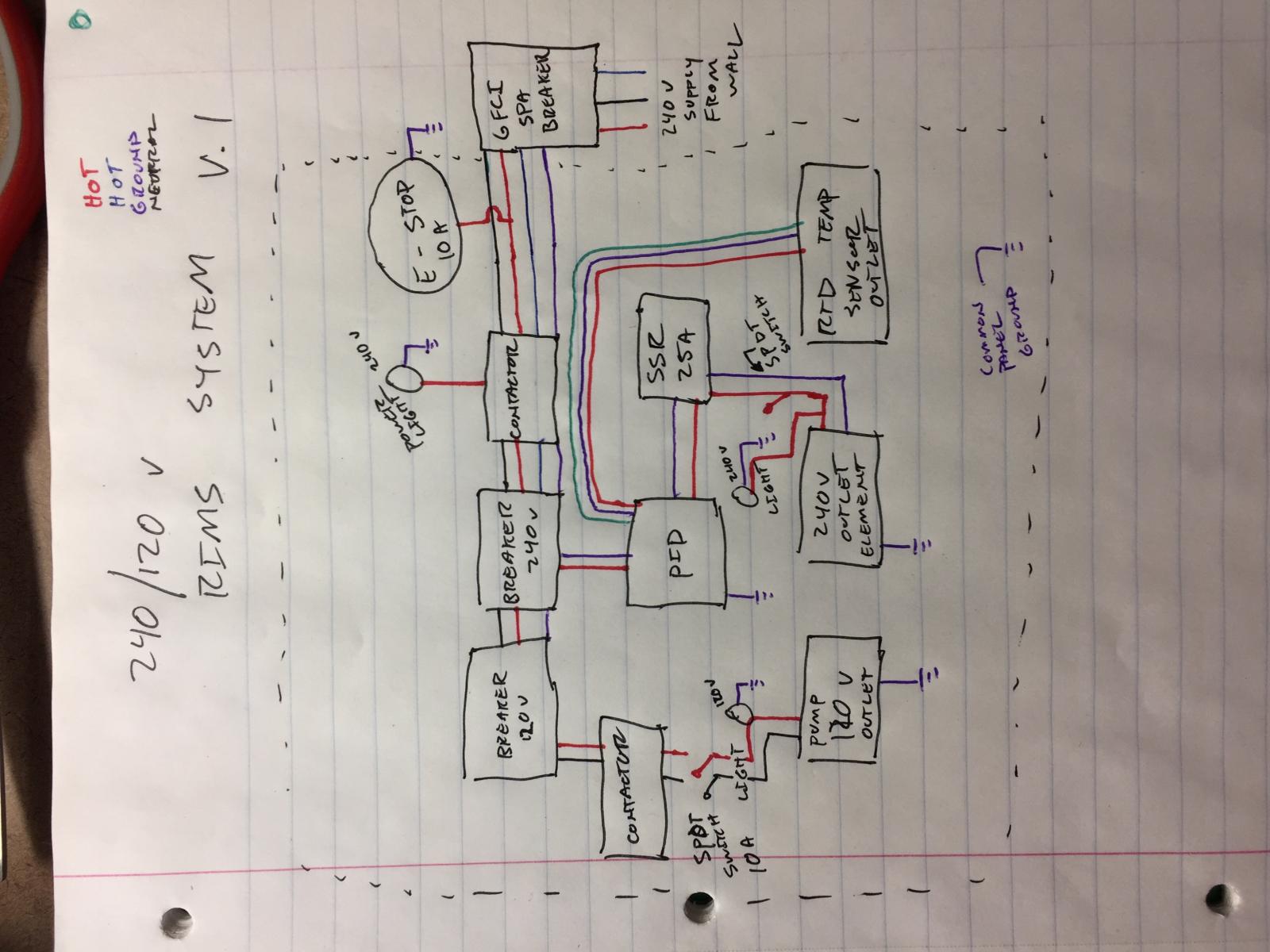

I have a few case grounds and I'm only familiar with cars/trucks for wiring. So this is a little new. But yeah I just wanted to lay something out on paper. How do I use 10A switches on a 30A circuit? I was thinking I needed bus bars but I started to get confused. Haha a lot more complicated then I first thought. However I start working on a more permanent diagram. Just never dealt with a neutral wire before.

With an AC circuit, the neutral serves as the return path for current from a load, much like a ground connection does in an automotive circuit.

In an AC circuit, the purpose of the ground connection is not as a return current path in the circuit. The ground serves a completely different purpose.

The purpose of the ground connection is so that all exposed metal surfaces of the brewery, i.e. panels, conduit, piping, kettles, framework and everything else metallic can be bonded back to the ground conductor coming from the breaker panel.

The reason for grounding everything is to protect persons who may come in contact with a energized metal surface if it accidentally makes contact with the hot conductors from the panel. In a single phase residential panel, ground should never conduct any current when everything is wired and working properly.

In properly bonded equipment, contact of an energized conductor to ground anywhere should immediately trip a breaker in the panel, or blow a fuse.

The way you use the 10 amp switch to control the 30 amp circuit is to use the switch to control a contactor that is rated for 30 or more amps.

The switch is used to energize the coil of the contactor, and the contactor carries the higher current load.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)