...

I have much respect for PJ and all the work he did providing schematics for folks on here... and have seen that you also are providing some great schematics yourself - good on you!!

Unfortunately, P-J isn't very (or at all) active on HBT anymore (his last post was about 11 months ago.) I'm trying to do what I can to fill in the large void left by P-J's absence, but certainly will not be able to fill his shoes.

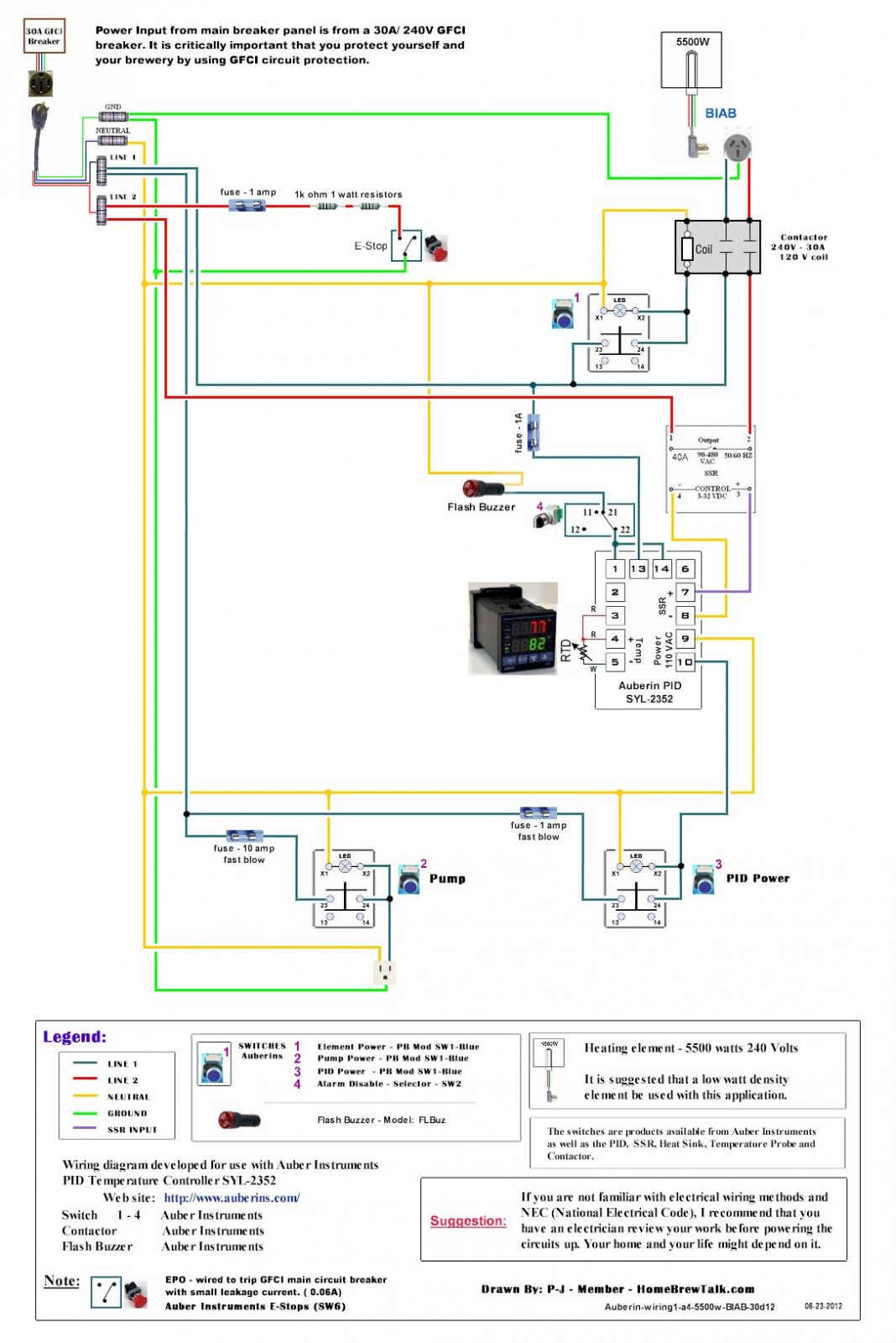

So maybe you can answer a question... Why did PJ choose to only switch one leg with the contactor through the PID/SSR? The element switch immediately supplies 120v to the element (approx 1375w) when it is closed leaving the other leg then controled by the PID/SSR to bring the 5500w element to its full potential. Logic - my probably faulty logic says switch the contactor coil via the PID/SSR and eliminate any power going to the element until the temp probe calls for it.

Yes 120V is supplied to the element when the contactor is closed and the SSR is off, but since the off SSR prevents any current from flowing, there is no power going to the element. If you measure the voltage between the two hot connections at the element when the SSR is off, you will read very close to 0V. If you measure the same points with the SSR on, you will measure about 240V. The element is just a resistor. When there is 0V difference between the ends of the resistor, there is no current flowing in the resistor, and no power is being dissipated by the resistor. When there is a voltage difference between the two ends of a resistor, then current is flowing thru the resistor, and power is being dissipated by the resistor. The power is given by I * I * R, where I = current and R = resistance (if I = 0, then power = 0.) Read the analogy between current and water flow, and pressure and voltage, that I

posted here. It may help you understand.

My thinking is that it was done this way to prevent such a drastic load being applied to the components each time the element kicks on and off to regulate temperature. And that the 1375w going to the element though sufficient to raise the temp of the kettle - even to a boil - would take so much time that it is not a huge factor weighed against the stress on the system by switching both legs simultaneously. Correct?

No, the SSR switches between 0 power and full power. There is never any partial power delivered to the element.

You don't want to actively control the element with a contactor, as it would be switching about 60 times a minute with a standard PID, and up to 1800 or 3600 times a minute if using a controller like the DSPR110. That much switching will wear out the contactor very quickly, and be very noisy.

NOTE... sort of unrelated question... Am I correct that the contactor is non-directional? Meaning I can put the input/output leads - both for the coil and the main switch - on either end/side? (I realize the coil requires a hot and a common, whereas the main switch is 2 hots in 2 hots out)

Correct, the contactor is non-directional, you can connect load or supply to either of the contacts. Remember, we are working with AC, so current flows back and forth in both directions, so the contacts have to be non-directional. A 120V coil requires 1 hot and 1 neutral, but it doesn't matter which is connected to a particular end of the coil. A 240V coil would require 2 hots to be connected.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)