It will work, its just not going to be very fast.

Look at it this way. Once the temp on the HLT water drops a bit the HLT heating element is going to kick in. At that point what you basically have is the HLT heating element heating the MLT contents via heating up the HLT water and running it through the CFHX. That is way, way slower and has way more heat losses and inefficiencies than if that element was operating directly on the MLT liquid as it would be in a RIMS. Probably 50% is lost between the heat lost from the HLT kettle, heat losses in the circulation loop, heat not conducted across the heat exchanger, etc. And if the HLT water temp falls at all, the HX rate really declines.

And the other thing is that you are heating way more thermal mass. Instead of the 5 Kw heating element having to heat the MLT, its now heating all the water in the HLT as well as the MLT.

One other issue with HERMs is temp overshoot. Lets say you want to do a step. So you heat up the HLT water like crazy and do the step. To be effective, the HLT water is going to need to be 30-40F hotter than the MLT water. Now the step is done. You'll probably want to continue recirculating, right ? If you do, your mash is going to continue picking up heat from the HLT water, at least until it comes down a bit. If the MLT and HLT have the same mass, the two temps will meet in the middle, over time. If the HLT water is 40F hotter than the MLT, the MLT mash will overshoot by 20F !

Lets do some calcs. You have a 5 Kw element. Lets say that overall you have 3KW of effective heating after all the losses. Lets say the HLT has 5 gallons (40 pounds) of water in it. Lets say the MLT has 6 gallons (50 pounds) of mash in it.

1 BTU = 1 lb F per hour

1 KWHr = 3412 BTU

3 KW = 10,236 BTU per hour.

We are heating 40 + 50 = 90 pounds of water.

10,236 BTU/90 pounds = 113 F per hour. I'd say this number over states the effectiveness, especially since it assumes that there is always a big enough delta T across the HX that it is effective.

I might be totally out to lunch. I highly suggest you test it with your plate chiller. Get some hose and plumb the MLT flow to go through the garden hose side of the plate chiller. Put 5 gallons of water in the MLT. Put 5 gallons of water in the HLT and heat it. Start circulating the MLT water and plot its temp over time. I'd love to see what you find.

My HERMS system used a direct fired HLT with a big immersion coil that I pumped the mash through and another pump circulating the HLT water. It worked, but it was slow. I was brewing lagers with 2 or 3 mash steps plus mash out and I spent a good part of my day waiting for the temp changes in my mash to occur. And my system had more heating power and less inefficiencies in that yours will. I was using an immersion coil instead of a CFHX. But at low delta Ts an immersion coil doesn't make as much of a difference compared to a CFHX as it does at high delta Ts, like it does when cooling wort.

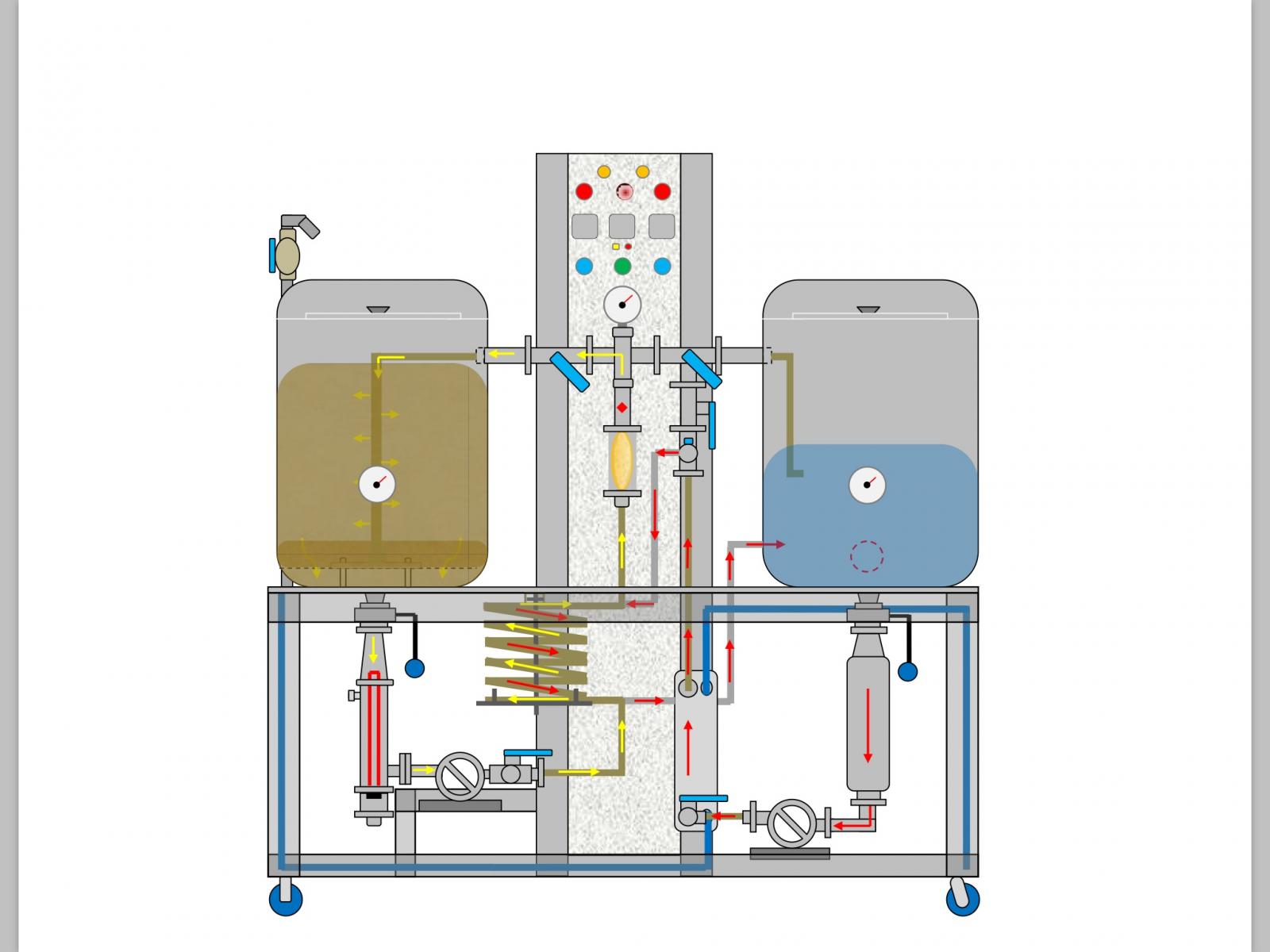

These posts have been a good exercise for me to remember and realize why I am working on my steam system. My steam system will be running at 30 PSI, providing heat at 275F to any processes that need it. Hot enough to be effective yet no chance of scorching, and its all electric. Hopefully it works in the real world.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)