scogan

Well-Known Member

- Joined

- Aug 7, 2022

- Messages

- 60

- Reaction score

- 33

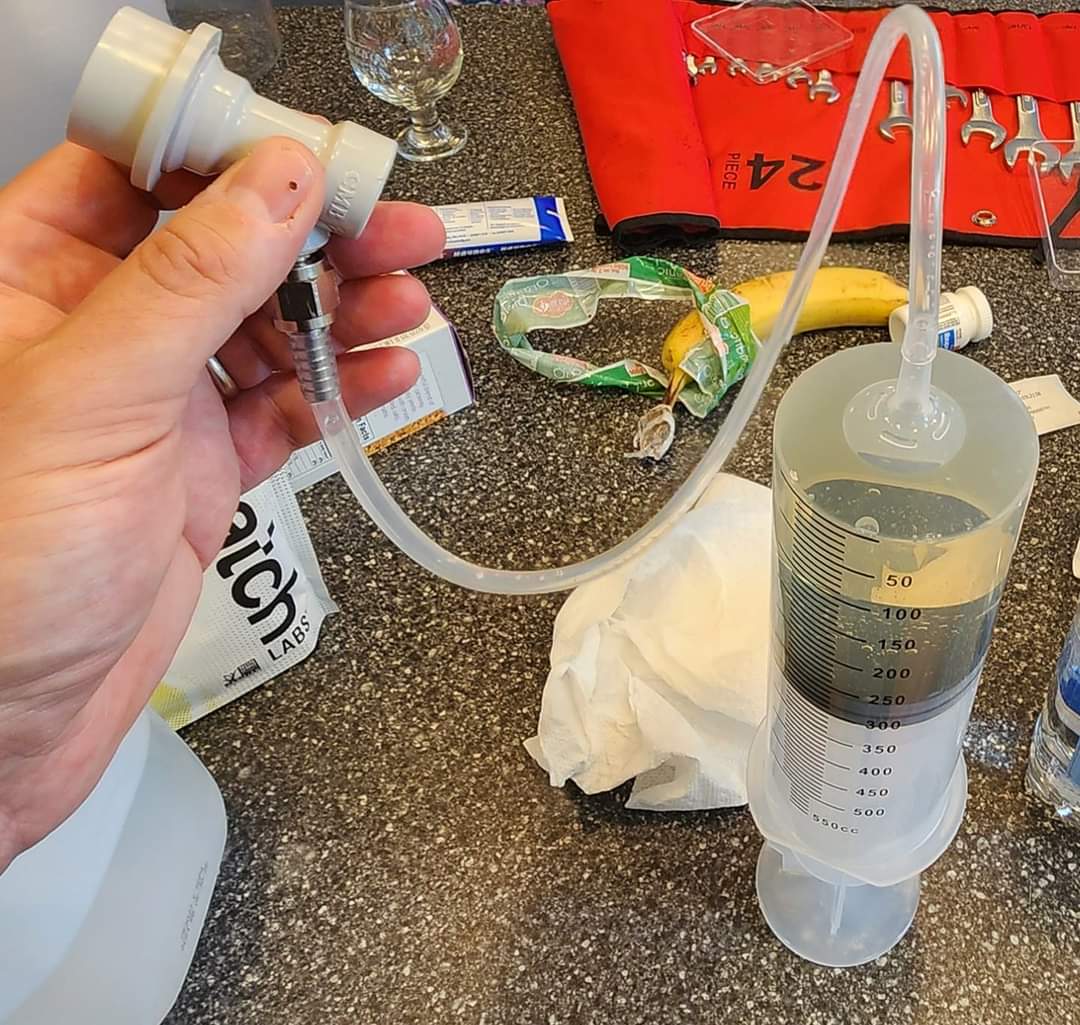

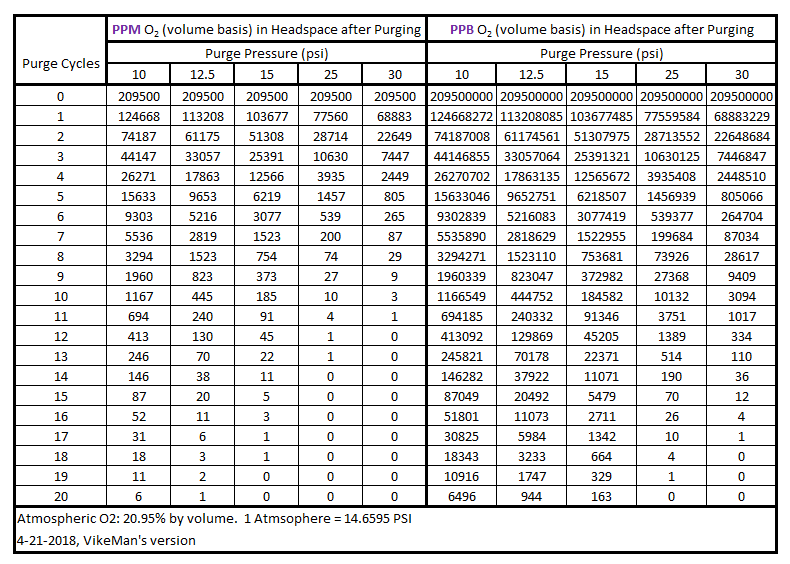

Before doing some extra dry hopping of some beer that was already conditioned I purged a keg recently by connecting it to my co2 bottle at 12psi and pulling the prv for a second or two twenty times.Hop aroma was tremendous , for about 3 days then pretty much disappeared.So ,the obvious culprit is oxidation,is there some adjustments to purging I should make ? Can`t do the displacing starsan routine because there are dry hops in the keg .Can`t remember what I did with jumper line, but I now fill them with beer first.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)