ElevenBrewCo

Well-Known Member

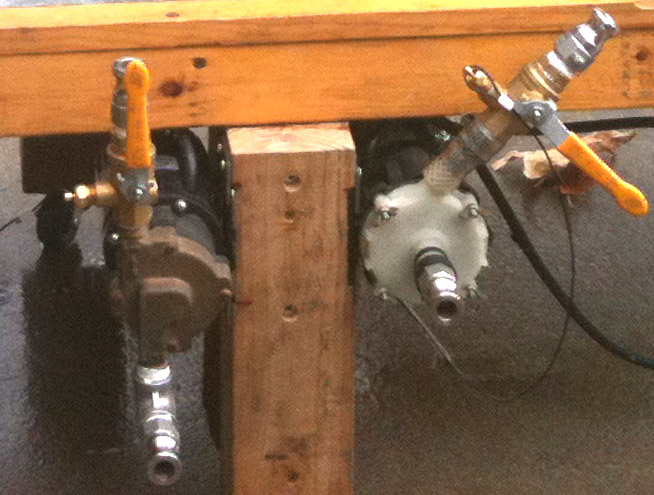

Wheres the best placement and orientation for my chugger pump. Currently i have it bolted laying down horizontal on the bottom of my stand with inlet on left and outlet on the right. I heard it deadhead a couple times today and wondering if it needs to be vertical so inlet is faceing down and outlet facing up?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)