You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Prototype Previews: Hopback and Heat Stick

- Thread starter Bobby_M

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tuesday

paul_111

Well-Known Member

Tuesday

As in Today? How long are they?

Still haven't arrived and I'm working on figuring out why. The length should be just over 13" but they tell me there are some variations from unit to unit

I've been testing my new system when I had time and I've left water in the hlt for over a week and no rusting on my SS Element.

Thanks Bobby.

PS. I did change the water when I brewed today! 😆

Thanks Bobby.

PS. I did change the water when I brewed today! 😆

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

Yes, I know. I'm equally disappointed.

I have to put it on the backburner because testing it out myself with any design changes requires that I pretty much brew a full batch of something hoppy, over and over. Once I get more employees in place to take some things off my plate, I'll be able to work on it more.

Just finished assembling my hot rod and am leak testing it now. Assembly is relatively easy and the product is really brilliant in its simplicity.

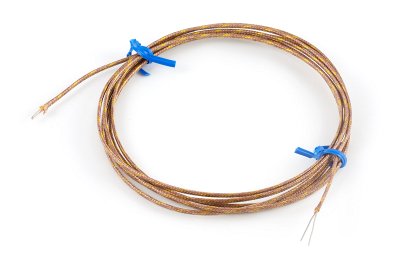

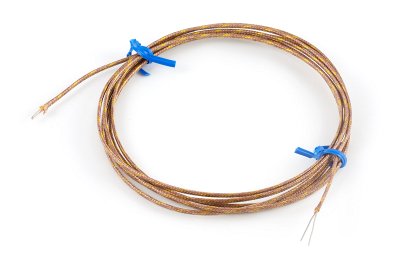

No home improvement stores around me had the recommended power cable available by the foot, so I had to buy a 25' spool. Also, the standard SJOOW cable was only rated for up to 100C. While that probably would have been okay, I didn't want to risk it and bought a slightly more pricey product rated up to 105C. The drawback is that now I have about 10-12' of cable that I'll probably never use.

If anyone is building one and would like to avoid having to go out and find cable, send me a message. If you pay for a shipping label, I'll send you the remainder of my 12-3 SJEOOW cable so long as you promise to put it to good use.

Edit: That was quick! Spare cable claimed.

No home improvement stores around me had the recommended power cable available by the foot, so I had to buy a 25' spool. Also, the standard SJOOW cable was only rated for up to 100C. While that probably would have been okay, I didn't want to risk it and bought a slightly more pricey product rated up to 105C. The drawback is that now I have about 10-12' of cable that I'll probably never use.

If anyone is building one and would like to avoid having to go out and find cable, send me a message. If you pay for a shipping label, I'll send you the remainder of my 12-3 SJEOOW cable so long as you promise to put it to good use.

Edit: That was quick! Spare cable claimed.

I think the 100C would be fine but I see your point. What I'm really trying to avoid is have people cut apart some extension cord with unknown temp rating and having a melt down.

brewnz

Well-Known Member

Hey Bobby, bought two hot rods from you and couldn't be happier! Do you have any plans on stocking 2000w or ideally 2500w 240v stainless elements? If so...Take my money!

rebelhill

Member

Bobby, any updates on the status of the ripple elements?

Very good chance they'll be here Friday.

I suppose this is a bit (a lot) off topic, but seems like there have been several new products introduced on this page. Would it be difficult to manufacture a 3/4in npt to 1/2 camlock fitting? The idea is that would make it easy to convert garden hose fittings to interface with our brewery hoses. Obviously you can do this with adapters now, but this could cut out that portion. I know it would make my life a bit easier. I have a few things in my brewery that would benefit from not having those extra couple of inches with added adapters, namely it would be truly awesome to have a camlock right on my utility sink. If I used adapters I would no longer be able to slide a carboy underneath it easily. Jet bottle washers would become so much more handy with a set of those on there. Rinsing brewing hoses would become a breaze. Hooking chilling water up, the list goes on.

Just a thought, I know you are always looking for new ideas to fit our needs!

Just a thought, I know you are always looking for new ideas to fit our needs!

orangehero

Well-Known Member

Garden hoses are not 3/4" NPT if I'm understanding your post correctly. You can get a female 3/4" GH x 1/2" Female NPT and attach a camlock fitting to that.

I suppose this is a bit (a lot) off topic, but seems like there have been several new products introduced on this page. Would it be difficult to manufacture a 3/4in npt to 1/2 camlock fitting? The idea is that would make it easy to convert garden hose fittings to interface with our brewery hoses. Obviously you can do this with adapters now, but this could cut out that portion. I know it would make my life a bit easier. I have a few things in my brewery that would benefit from not having those extra couple of inches with added adapters, namely it would be truly awesome to have a camlock right on my utility sink. If I used adapters I would no longer be able to slide a carboy underneath it easily. Jet bottle washers would become so much more handy with a set of those on there. Rinsing brewing hoses would become a breaze. Hooking chilling water up, the list goes on.

Just a thought, I know you are always looking for new ideas to fit our needs!

Stainless versions of these would be cool. http://www.tractorsupply.com/webapp...d=10151&pageSize=&filterTerm=&catalogId=10051

It's not that a garden hose thread to camlock fitting couldn't be machined in one piece, but rather whether many people would be willing to pay the premium cost over the combination of GHT to NPT and NPT to cam. It would require a pretty large piece of hex stock and the resulting machine time would be pretty costly. I'll still look into it though.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

A bushing might be a nice solution....internal threads would be 1/2" FPT allowing you to thread it over existing 1/2" MPT camlocks, and the outside threads would be GHT....you would still be able to keep the length down, and adapt to a garden hose in just one fitting.

I've actually adapted camlocks to my garden hose out of necessity, regular garden hose disconnects kept leaking everywhere making a mess and creating a dangerous situation with electricity nearby. No leaks whatsoever and they don't require a wrench....and for my limited homebrew use, they are almost as sanitary as triclovers, at a fraction of the cost. :rockin:

I've actually adapted camlocks to my garden hose out of necessity, regular garden hose disconnects kept leaking everywhere making a mess and creating a dangerous situation with electricity nearby. No leaks whatsoever and they don't require a wrench....and for my limited homebrew use, they are almost as sanitary as triclovers, at a fraction of the cost. :rockin:

Can anyone tell me the wall thickness of the hotrod?

Do you mean the down tube? I believe they are .035"

If you need to bend it, you'll need a mandrel tube bender.

If you need to bend it, you'll need a mandrel tube bender.

Do you mean the down tube? I believe they are .035"

If you need to bend it, you'll need a mandrel tube bender.

Yes the down tube is what I was after. Thank you.

I'm having a hard time finding someone with a 5/8 od bender around here. One place I have checked with asked me the wall thickness.

Derp

Well-Known Member

Any estimate of when the HotRod will be back in stock?

Cheers!

Cheers!

Should be about 2 weeks. I doubled up the quantity for this run so hopefully it will never be out of stock again.

I have been trying to read though this thread but there is just so much to it, 3 days later I have still not yet found enough time.

Bobby can you answer this, are you still thinking about putting in a thermowell or anything like that on the Hot Rod Heat Stick? I would like to buy one when they get back in stock but if that option is still on the way I might need to wait for that.

Also I am thinking about getting on of these:

http://www.amazon.com/dp/B0037NXKY0/?tag=skimlinks_replacement-20

That way I am not limited to a GFCI specific outlet. Any input?

Bobby can you answer this, are you still thinking about putting in a thermowell or anything like that on the Hot Rod Heat Stick? I would like to buy one when they get back in stock but if that option is still on the way I might need to wait for that.

Also I am thinking about getting on of these:

http://www.amazon.com/dp/B0037NXKY0/?tag=skimlinks_replacement-20

That way I am not limited to a GFCI specific outlet. Any input?

Last edited by a moderator:

I've determined that there is no need for an extra part for a thermowell. You can pull a standard thermocouple/RTD probe into the downtube and lodge it against the metal of the tube to conduct heat. Ideally, it would be a bare junction, well one that is insulated from shorting with a dab of epoxy or heat shrink. Some of the cheaper probes that are made from a drilled out M6 bolt for example, can be taken apart and the inside junction removed.

The bare type is sometimes called a "bead" thermocouple.

Even with a narrow stainless jacket left in place on some probes, the heat is conveyed within +/- 3F or so which may or may not be accurate enough.

One thing I have not had a chance to play around with is potentially a decent solution is to use the M6 bolt that is part of the PT-100 probe as the bolt to attach the ground wire. The reason it may work is that I have an M6 nut welded inside the enclosure for the ground. I just don't know if it will catch enough threads to be secure.

The link to that GFCI seems fine.

The bare type is sometimes called a "bead" thermocouple.

Even with a narrow stainless jacket left in place on some probes, the heat is conveyed within +/- 3F or so which may or may not be accurate enough.

One thing I have not had a chance to play around with is potentially a decent solution is to use the M6 bolt that is part of the PT-100 probe as the bolt to attach the ground wire. The reason it may work is that I have an M6 nut welded inside the enclosure for the ground. I just don't know if it will catch enough threads to be secure.

The link to that GFCI seems fine.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)