Snuffy

He ain't scared.

- Joined

- Nov 5, 2019

- Messages

- 1,937

- Reaction score

- 3,099

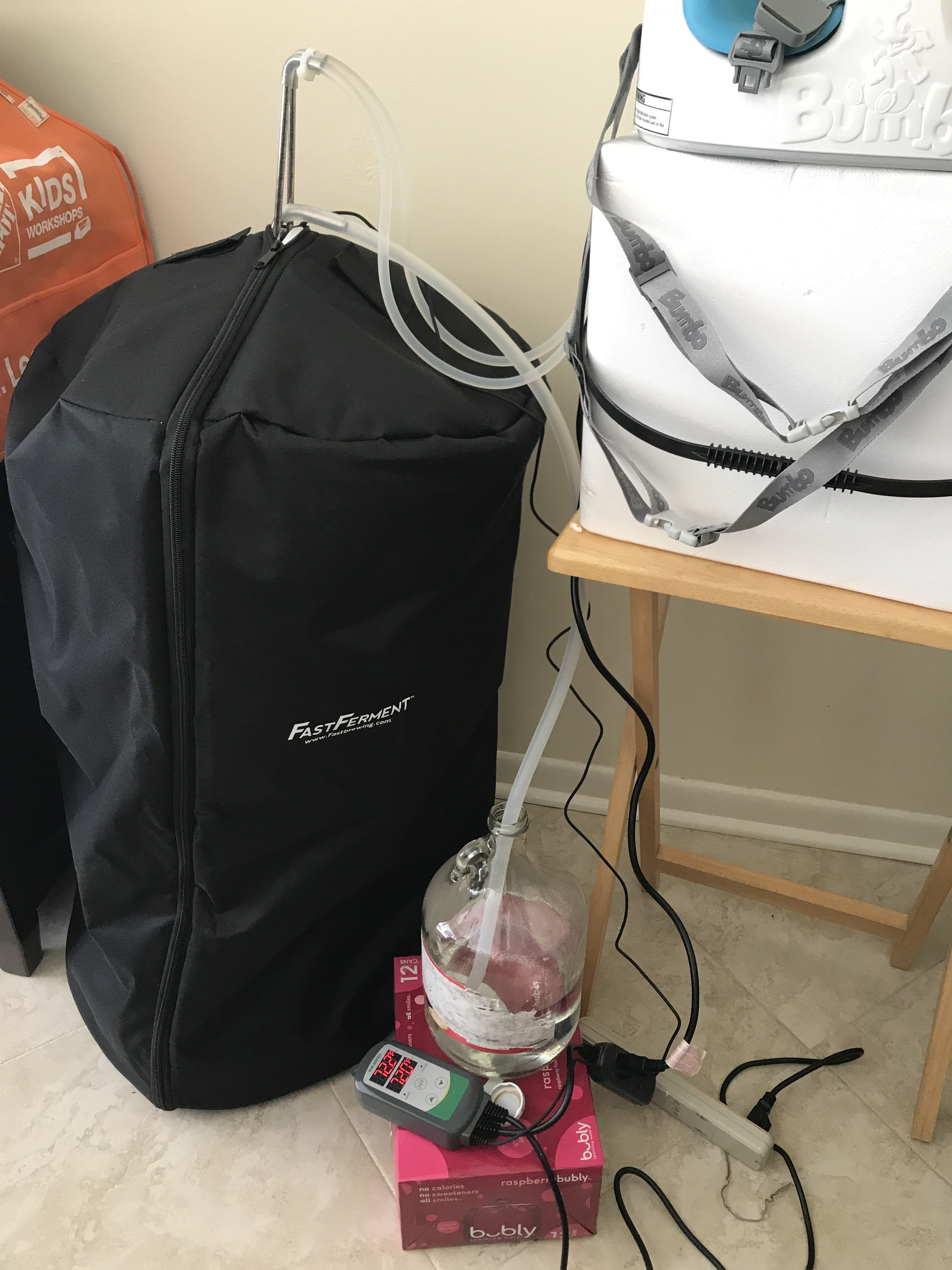

I bought one of the 3 gal FF units to do half-batches. It works fine once you understand how to work around it's issues. It's a PitA to get it water-tight to start with but I have learned using about 5 layers of plumbing tape on the threads where the valve attaches to the bulb and it won't drip. Also, I had issues where the valve body would not detach from the jar unit without causing a leak. I had it screwed down so tight it didn't want to unscrew again w/o loosening other connections that needed to stay tight. I had to siphon out of it because it wouldn't come apart once. After that I started using keg lube on all the o-rings and they come apart without leaking now. Keg lube also helps the leaky screw top o-ring seal like it should. It makes good beer when you get it tweaked, but its kind of a bitch getting there. You gotta leak test the crap out of it without screwing the bits together too tight. I think I paid about 45 bucks for it. Doesn't strike me as a long term piece of equipment. I'd have paid twice that if it was built better.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)