Why does my Best Bitter pour like that? I've poured 3 glasses in a row now so the line should be cold already

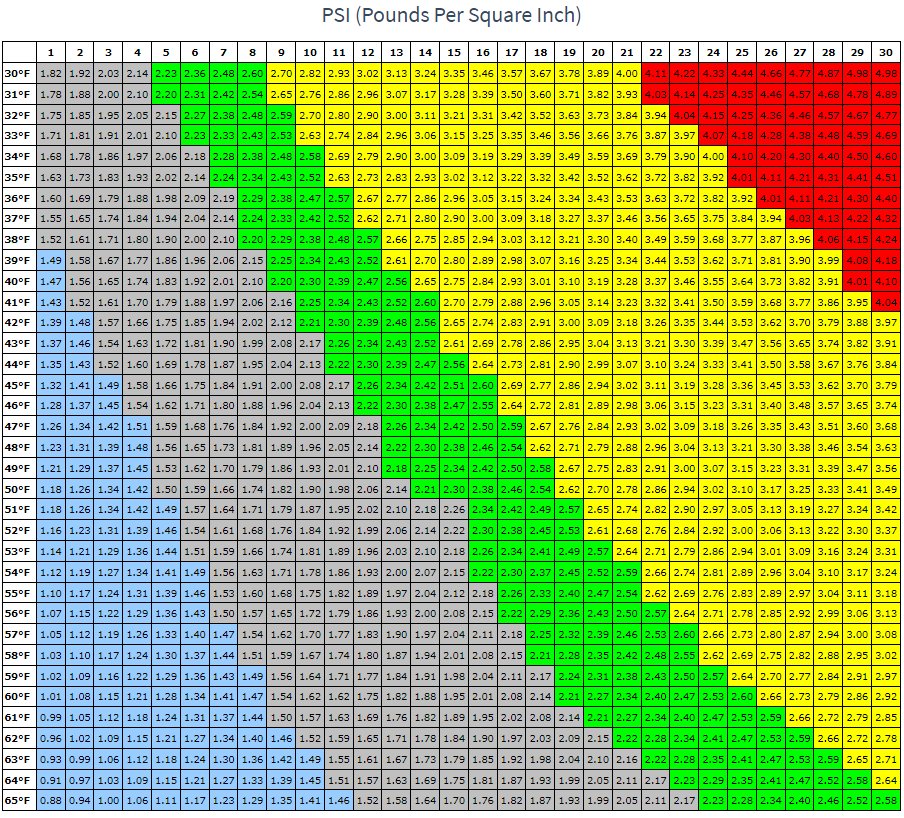

I'm using a KegLand picnic tap on a 19L keg and the serving pressure is around 10-11psi.

There's around 15-16L in the keg now.

I originally set the pressure to 20psi, then cooled it to 2°c for two days and then now the beer has been in a 8c° fridge for a few days under 9psi.

This is my first time kegging. Only used bottles so far with good success but to much labour in bottling.

So what do you guy's think I'm doing wrong?

And those of you that have kegged a bitter with success what was your method?

Cheers!

I'm using a KegLand picnic tap on a 19L keg and the serving pressure is around 10-11psi.

There's around 15-16L in the keg now.

I originally set the pressure to 20psi, then cooled it to 2°c for two days and then now the beer has been in a 8c° fridge for a few days under 9psi.

This is my first time kegging. Only used bottles so far with good success but to much labour in bottling.

So what do you guy's think I'm doing wrong?

And those of you that have kegged a bitter with success what was your method?

Cheers!

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)