Hi guys I am having trouble getting any beer or pressure out of my faucet.

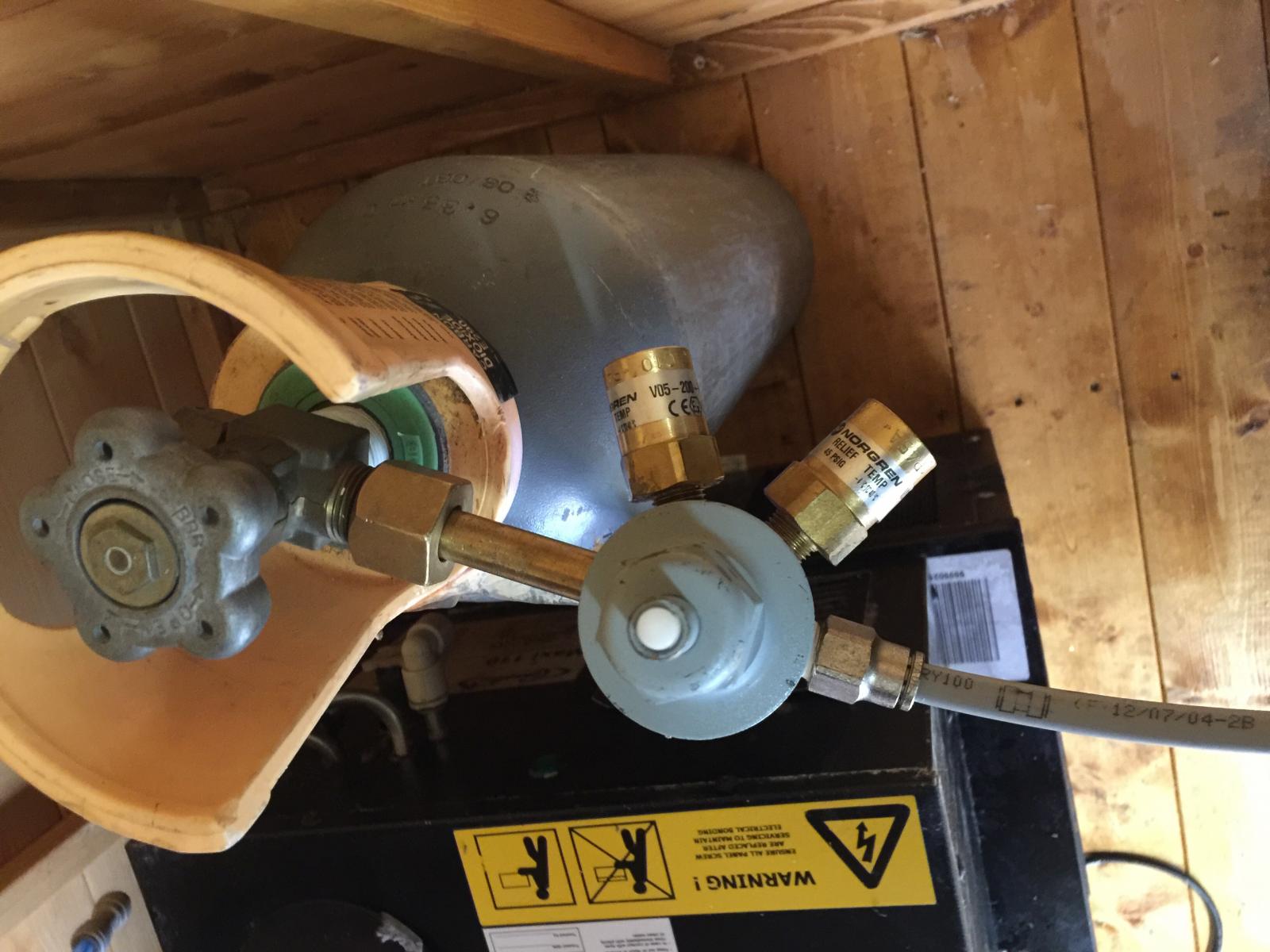

The set up I have is a 11 gallon keg (Stella Artois) on top of that is obviously a keg coupler to a bottle of co2 and a new regulator.

Then from the keg coupler again the other line goes to the faucet.

There is literally nothing or any pressure coming from the tap.

The coupler is locked in place and clamped down properly and also a lot of pressure from co2.

Am I doing something stupid here?

Any help would be great!!

The set up I have is a 11 gallon keg (Stella Artois) on top of that is obviously a keg coupler to a bottle of co2 and a new regulator.

Then from the keg coupler again the other line goes to the faucet.

There is literally nothing or any pressure coming from the tap.

The coupler is locked in place and clamped down properly and also a lot of pressure from co2.

Am I doing something stupid here?

Any help would be great!!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)