GoodaleBrewing

Active Member

So I have been prepping to make an electric setup that I can use in my basement to get out of the cold of my garage in the winter. I plan on going with a 3 keg build with 2 pumps either way and am weighing my options on control box. I had planned on building a kal clone style 3 PID setup but every time I come into the electric brew section I see post about Raspberry PI builds (Strange Brew). Can anybody give a good pros and cons list between the two setups.

What I think is correct already.

Pros of PIDs

Actual switches you can touch

Cons

More difficult to expand (case space)

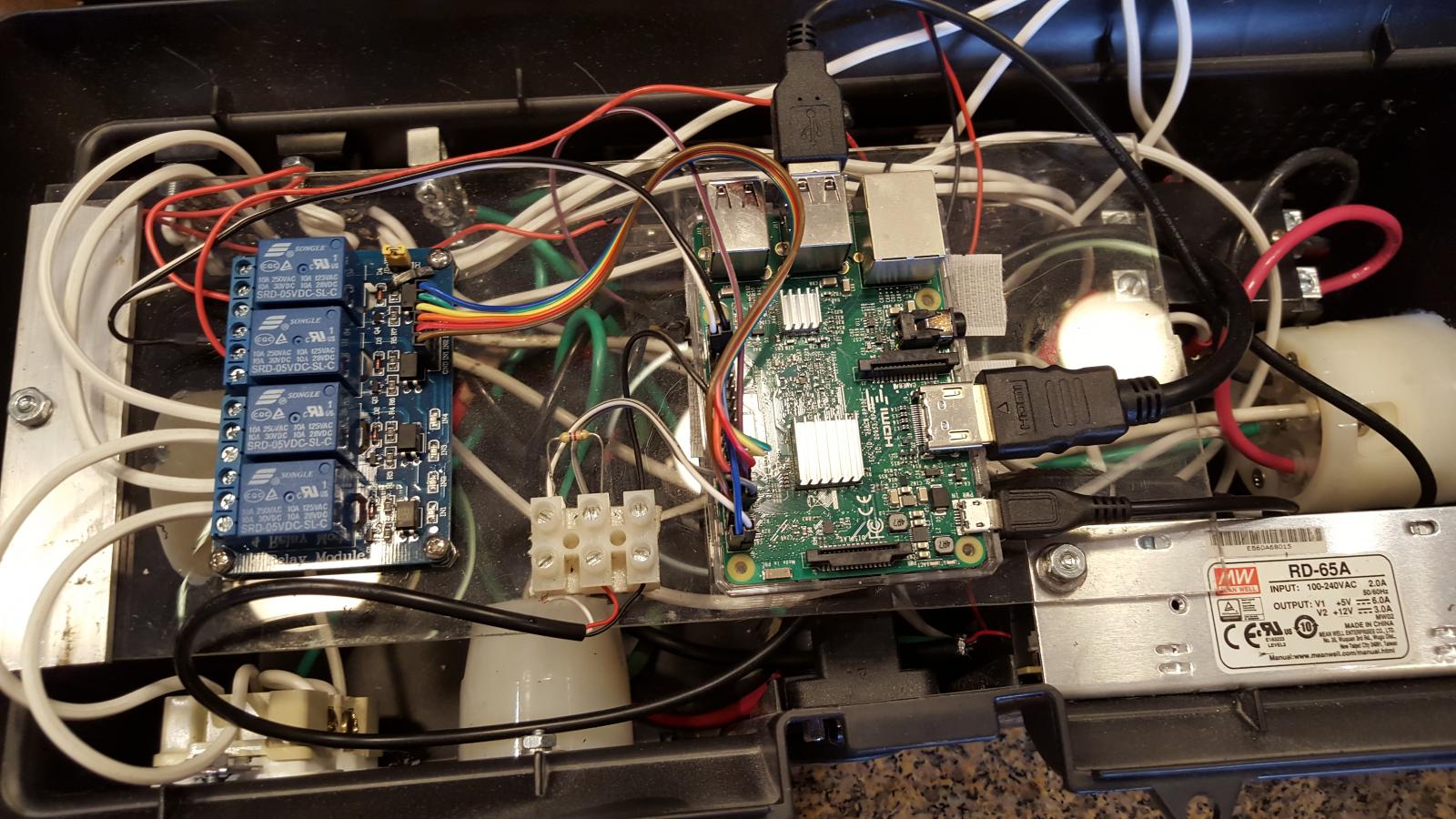

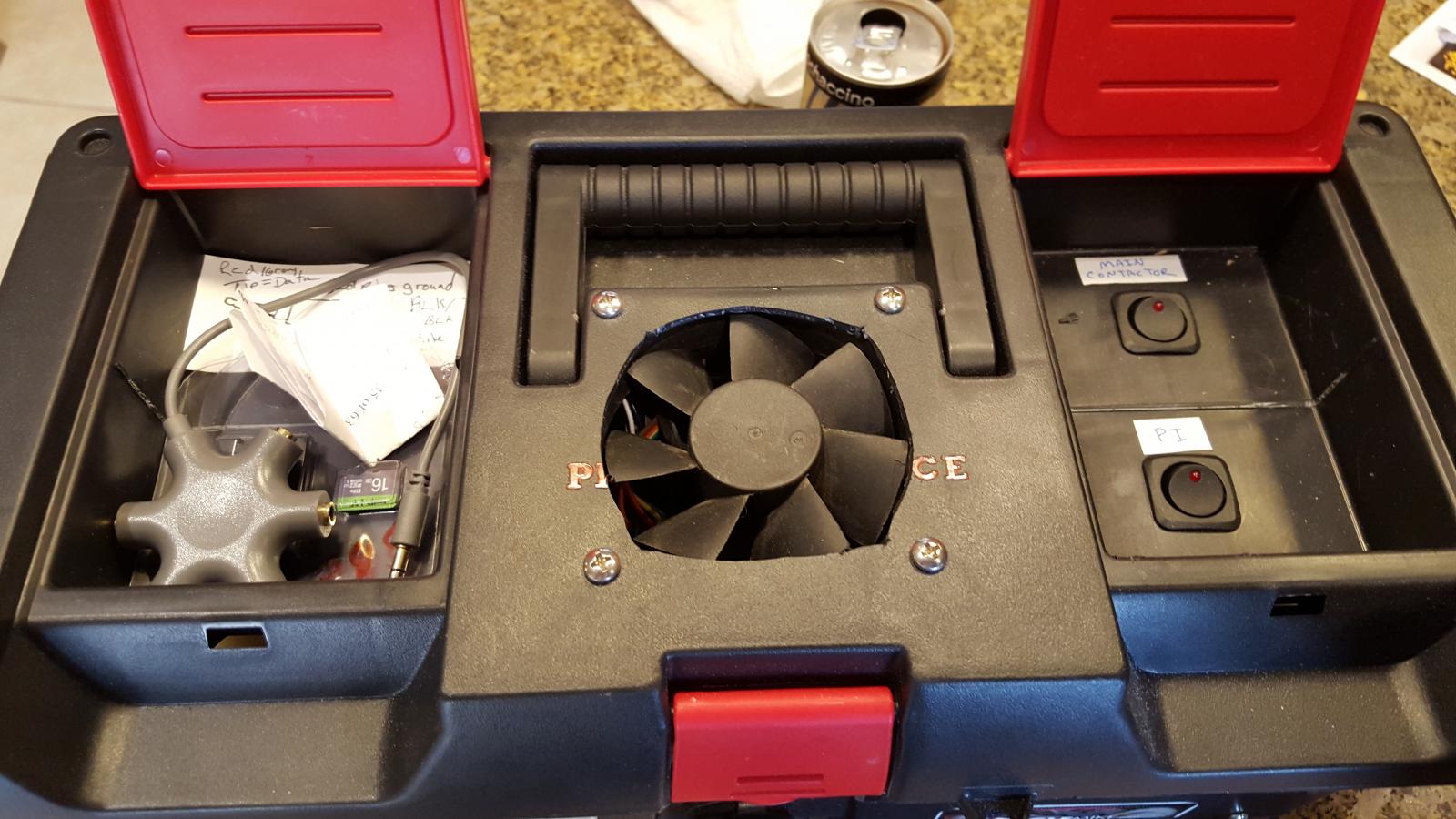

Pros of Rasberry Pi

Cheaper?(depending on touch screen)

Easier expansion and layout changes (if you have room inside the case)

Cons

Without screen relies on internet connection (will probably use a screen anyway)

Errors with Raspberry Pi??

What I think is correct already.

Pros of PIDs

Actual switches you can touch

Cons

More difficult to expand (case space)

Pros of Rasberry Pi

Cheaper?(depending on touch screen)

Easier expansion and layout changes (if you have room inside the case)

Cons

Without screen relies on internet connection (will probably use a screen anyway)

Errors with Raspberry Pi??

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)