I have to believe these exist, but so far no luck on Google...

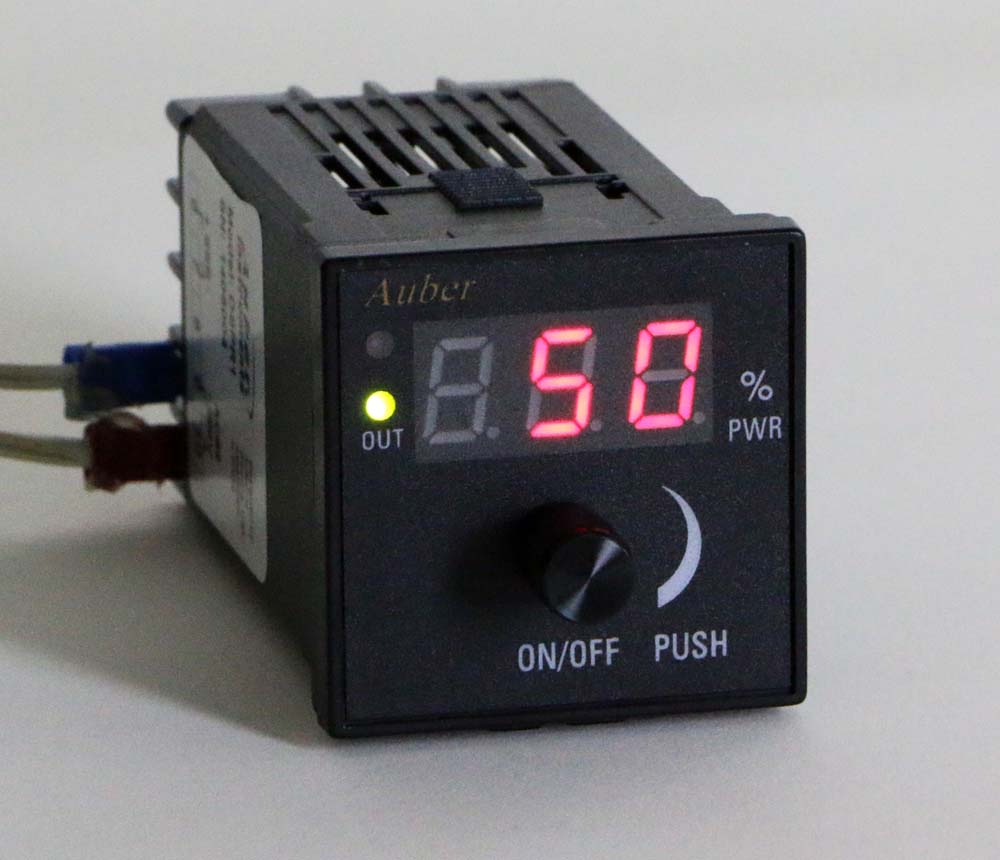

Anyone know of or use a PID with a stove-like dial for manual mode during boils?

Right now I'm using just a basic potentiometer with an SSVR. It works like a champ for boils with the turn dial, but I'm always overshooting my strike water and sparge temps.

I realize I could break this up into two separate controls, but unless it's cost prohibitive, having one PID to control my HLT and BK seems ideal to me.

Anyone know of or use a PID with a stove-like dial for manual mode during boils?

Right now I'm using just a basic potentiometer with an SSVR. It works like a champ for boils with the turn dial, but I'm always overshooting my strike water and sparge temps.

I realize I could break this up into two separate controls, but unless it's cost prohibitive, having one PID to control my HLT and BK seems ideal to me.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)