- Joined

- Mar 23, 2018

- Messages

- 290

- Reaction score

- 178

No update again last week....

Regular updates...no good deed goes unpunished.No update again last week....

I guess I should apologize for trying to take a company that is sitting on $2500 of my money at their word. That word is, specifically:Regular updates...no good deed goes unpunished.

Be on the lookout for weekly email updates every Friday, so you can follow along with our progress. Lastly, thanks for hanging in there with us... the product is getting better every day and we are only more excited to get it out to you!

Apologies for missing our regularly scheduled Friday update, we were awaiting a key part delivery

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I met with both the PicoBrew and Grainfather staff at GABF... and ended up ordering a Grainfather /w the micro pipework. It will be here next week.

I like the fact that there is a little time. If the Brewie shows to be reliable (which facebook group shows some issues so far) that I can just cancel my z2 and move onto that instead!

Pico's issues are the guys developing the product don't seem to be communicating with the marketing idiots and the marketing idiots seem to also be the customer service staff which is not a good combination/strategy.

I know that everyone including PicoBrew recommends to put a spoon or keg lid rings between the large filter mesh and the plastic step filter lid. This is what I did (using the same fix implemented for the Braumeister malt tube top screen: Used McMaster-Carr high-temperature food grade silicone U-channel gasket over and around the edges of the filter mesh. The U-channel gasket seals the screen so no grains can escape. I did not do the small bottom screen because the weight of the grain keeps it in place. Feedback is appreciated.View attachment 586046

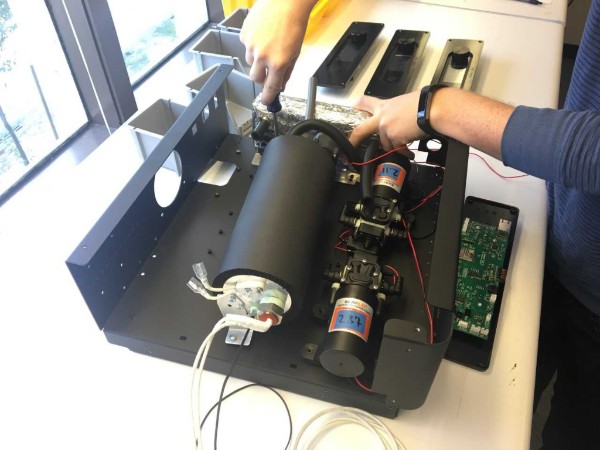

All Zymatic machines were hand-built. Most of the Z will be hand built. Parts of it can be assembled by parts manufacturers' - we will be assembling them at our facility in Renton, WA. Cheers!First unit is apparently going out tomorrow, but it's hand-built and being hand-delivered, so certainly not full-production mode.

That's nice - the new Z screens a somewhat similar - but the shape is different as the StepFilter is very different. I'll try and post some pictures for you peeps!So I got the u-channel seals from McMasterCarr and put them on all the screens to prevent grains and husks from clogging up the in-line filter and just keep the wort a lot more clear. What I have learned is that sometimes, the seals work too good.

Since the screens are so fine, air pressure tends to build up between the two screens and surface tension literally causes the wort to just roll off the top screen and into the overflow. I also observed that air pressure below the bottom screen prevented wort from seeping through and into the bottom of the step filter.

View attachment 591371

After some experimentation and fiddling around, I was able to solve the problem for the lower step filter screen and the adjunct compartment screen and really should have seen that from the beginning as there are pressure slots built into the screens. If you add these seals, you need to cut the holes out for the slots to allow the trapped air a chance to escape and equalize the pressures between the grains and the step filter.

View attachment 591373

View attachment 591374

Still working on a solution for the upper screen, but for now, I just removed one of the screen seals so that trapped air had an exit path. That still allows me to avoid using the keg o-rings to hold the upper screen in place and with three seals on the screen still prevented floating grain husks from going into the overflow.

There are quite a few micro-breweries developing on the Zymatic....Herbfarm is a great example. You think they know that their recipes are open to anyone at Picobrew? None of us signed an NDA or anything....what's in their DB is technically theirs.

Yeah. ZX-Ventures (inbev). They own em. Along with northern brewer and midwest. This isnt new or anything. The tinfoil nutters such as myself assume this is to disrupt the homebrew market. A term they use a lot. Or otherwise to ensure you have to go through their paywall somehow.

Yeah seems more like a prototype that is going out for testing.

Curious to see what the testing actually shows once things get moving. Wanting to get into a less hands on brew system and the very few reviews I have seen of Brewie+ have been surprisingly positive (granted they aren't shipping their pre-ordered units only new orders which seems shady). Hoping that the Z produces as I have a Z2 on pre-order but not afraid to cancel if they don't really produce the desired results.

You have some bad information

QoB, last week I asked a question about the best way to protect a Z2 in a garage brew station, which sometimes gets below freezing. Do you have any insights on that?

Another falsehood. Zx Ventures is a minority debt holder.

Cheers!

Obviously all the LogSession data could just be built up in memory (or written to a disk) during brewing that upon completion could be uploaded to the "home base" with no loss of data to PicoBrew and just a lack of visibility for us brewers.

If I were to build this machine or work on the firmware this is exactly what I'd do...

Doubt it. But being a belligerent bully or cursing and swearing at customer service reps will.^ BTW asking questions like that will get you banned by Pico.

Doubt it. But being a belligerent bully or cursing and swearing at customer service reps will.

Mike got banned for way less than that.