Yesterday was an attempt at a two brew day. Started at 10:30am when I flipped switch on first and done cleaning up after second by 11pm. So....it can be done, but it makes for a LOOOONG day.

First brew was a heady topper inspired IPA. Lesson here is that the Zymatic does NOT like huge hop whirlpools. The brew had one hop bag in the keg at 190F for 10 and another hop bag in the keg at 160 for 20 minutes. I also swirled the keg a few times each addition. I used the 'circulate' option under Help to transfer to carboy (has worked great in past) but machine clogged up 3-4 times (I lost count). Had to pull out the inline filter and scrub it clean, then resanitize, restart circulate...repeat a number of times. (DEFINITELY not the most sanitary approach, but hope I did it well enough.)

Really not sure how to avoid this in future. I believe it was starting to clog even during the chilling recirc as it got really bubbly in the return line before it clogged up completely.

(How to tell if it is clogged? The output is VERY bubbly and foamy and no real liquid. Also sound will change when no more wort is being pulled into the machine. I think it got a bit lower in pitch.)

Second brew was a @Yooper designed clone of Stone's Ruination. This one was pretty uneventful and it only had one whirlpool bag in the keg. I believe I had to pull filter and clean once during the transfer. The interesting thing was brewing a MO base malt and then a 2row base malt back to back was the wild difference in aromas. (I definitely like the mash aroma of MO. The 2row was very astringent and sharp compared to that.)

Clean up inbetween brews took right about 45 minutes to turn around and have second one going. That's not bad.

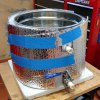

Also, the putting the keg into a brew bucket of 2gal ground temp water has been working wonders for chilling. Three changes of water get the wort down into sub-100F range and then I put it into fermentor to reach pitching temps. I pitch the next day and seems to be working great so far.

Another lesson I am trying to fine tune....efficency. My recipes in Brewer's Friend have to be set between 60% and 62% eff to get the same estimated OG that PicoBrew gives me. It kinda bothers me to be leaving that much sugar in the grains... :-(

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)