Hi all,

This is my first time posting here so please forgive me if this is in the wrong place, or if there are better threads that answer these issues.

I am a somewhat experienced brewer. I have brewed at least 30+ batches with no problems, in a wide variety of ale styles (stouts, porters, pales, belgians, scotch ales, etc). At this point I have a good idea of what the beer I'm making is supposed to taste like, and how certain yeast strains impart flavor.

About a year and a half ago, I got an infection in a Belgian ale, I think from the sugar addition I put into the primary, roughly 4 days into fermentation. I had always put sugar syrups in at this time to not overload the yeast at the start, and had not had any problems up until this point. My sugarmaking process entails heating up cane sugar to roughly 280 degrees with DAP, which then goes into a mason jar I had sterilized with boiling water previously. For this batch I had neglected to sanitize the spoon I scooped the sugar out of the jar, and I think this is where the infection came from. Before I put the sugar in, I took a gravity reading and tasted the beer, thinking it was an interesting take on the recipe (the brew store was out of a bulk of the grains I normally used and I had to make a bunch of substitutions). A week after the sugar addition during racking to the secondary, it tasted horrible, incredibly soured tart flavor that overpowered literally every other flavor.

Since then, I have thrown out my siphon, tubing, bottling wand and bottling spigot, as well as bought new plastic fermenters. I've had issues with infections ever since. Out of the last 10 batches I've made in the last year, only 3 haven't had issues. Some have the overpowering tart/sour taste that completely drowns out everything else, others have a strong vinegar taste, with the taste of proper beer noticeable, but just barely. I'm at my wits end and probably going to give this up as a hobby if I cant figure out something.

When cleaning my equipment at the end of the last batch I bottled, I noticed some blackish smudge on one of the washers on my bottling spigot. I believe my last two batches got infected during the bottling stage, and I strongly suspect this is the culprit. I plan to throw out my bottling bucket, bottling wand, spigot, siphon and tube and buy additional ones. I'm not sure if I should also throw out my plastic fermentation buckets.

At this point I have probably read every infection thread on the internet multiple times and cannot figure out solutions on why these problems keep reoccurring after discarding my equipment previously. My process, brewing, fermentation and storage locations have not changed since I was able to produce good beer.

Virtually all the threads on the internet say something along the lines of infections are caused by poor sanitation. Before I rack and bottle, everything that touches the beer gets soaked in PBW, rinsed, then soaked in Starsan. For the bottles themselves, they all get submerged in Starsan, drained, then filled with the beer.

At this point I have several questions:

- how airbourne are infectious bacteria? Ie, if I have an infected washer on a bottling spigot, would it be able to infect a bucket that is stored 10 feet away? Likewise, would an infected bucket infect another bucket that is a few feet away? Could an infection transfer onto the shelf that I'm storing things on?

- while I suspect infections are taking place during the bottling stage in these last few cases due to the beer tasting fine during the bottling process and taking on vinegary hues 3-4 weeks after bottling, I'm not 100% of this. What are the chances the beer has been infected in the primary and somehow laying dormant and not quite manifesting itself until weeks into the fermantation/aging process? In the case of that Belgian mentioned above that I know was infected in the primary, I could taste it right away. But some people say that infections don't always manifest themselves that quickly

- could the environment itself be infecting my equipment? I store all my brewing stuff in my attic on the same plastic shelving unit

- I boil and cool uncovered, both outside. I've heard some people suggest fruit flies are a source of infection, but I have never seen them, and I try to do most of my brewing in the winter, as I like to seasonally brew as to avoid using things like swamp coolers. Should I be covering during the cooldown process?

- Likewise, my bottling bucket is uncovered while bottling. Should a lid go on top after everything gets transferred in the bottling bucket?

- When I make my priming solution, I boil roughly 100 g of sugar in storebought spring water in a covered pot for roughly 15 minutes. While I clean the pot beforehand, I've never sanitized it, as I always assumed that having something at a boil for 15 minutes would kill any bacteria in the sugar, and that the temperature would be enough to sterilize the pot and lid. Is this an incorrect assumption? Should I be sanitizing the pot as well before I boil the sugar?

- Likewise, I'm assuming that putting sugar syrup additions a few days into the primary is now a Bad Idea, and it should be put in the boil to avoid possible infections at this stage. Other people seem to not have problems, but I assume the less infection points the better?

Any input would be appreciated. It sucks to have to punishment drink 50 sour beers when they should be delicious porters.

This is my first time posting here so please forgive me if this is in the wrong place, or if there are better threads that answer these issues.

I am a somewhat experienced brewer. I have brewed at least 30+ batches with no problems, in a wide variety of ale styles (stouts, porters, pales, belgians, scotch ales, etc). At this point I have a good idea of what the beer I'm making is supposed to taste like, and how certain yeast strains impart flavor.

About a year and a half ago, I got an infection in a Belgian ale, I think from the sugar addition I put into the primary, roughly 4 days into fermentation. I had always put sugar syrups in at this time to not overload the yeast at the start, and had not had any problems up until this point. My sugarmaking process entails heating up cane sugar to roughly 280 degrees with DAP, which then goes into a mason jar I had sterilized with boiling water previously. For this batch I had neglected to sanitize the spoon I scooped the sugar out of the jar, and I think this is where the infection came from. Before I put the sugar in, I took a gravity reading and tasted the beer, thinking it was an interesting take on the recipe (the brew store was out of a bulk of the grains I normally used and I had to make a bunch of substitutions). A week after the sugar addition during racking to the secondary, it tasted horrible, incredibly soured tart flavor that overpowered literally every other flavor.

Since then, I have thrown out my siphon, tubing, bottling wand and bottling spigot, as well as bought new plastic fermenters. I've had issues with infections ever since. Out of the last 10 batches I've made in the last year, only 3 haven't had issues. Some have the overpowering tart/sour taste that completely drowns out everything else, others have a strong vinegar taste, with the taste of proper beer noticeable, but just barely. I'm at my wits end and probably going to give this up as a hobby if I cant figure out something.

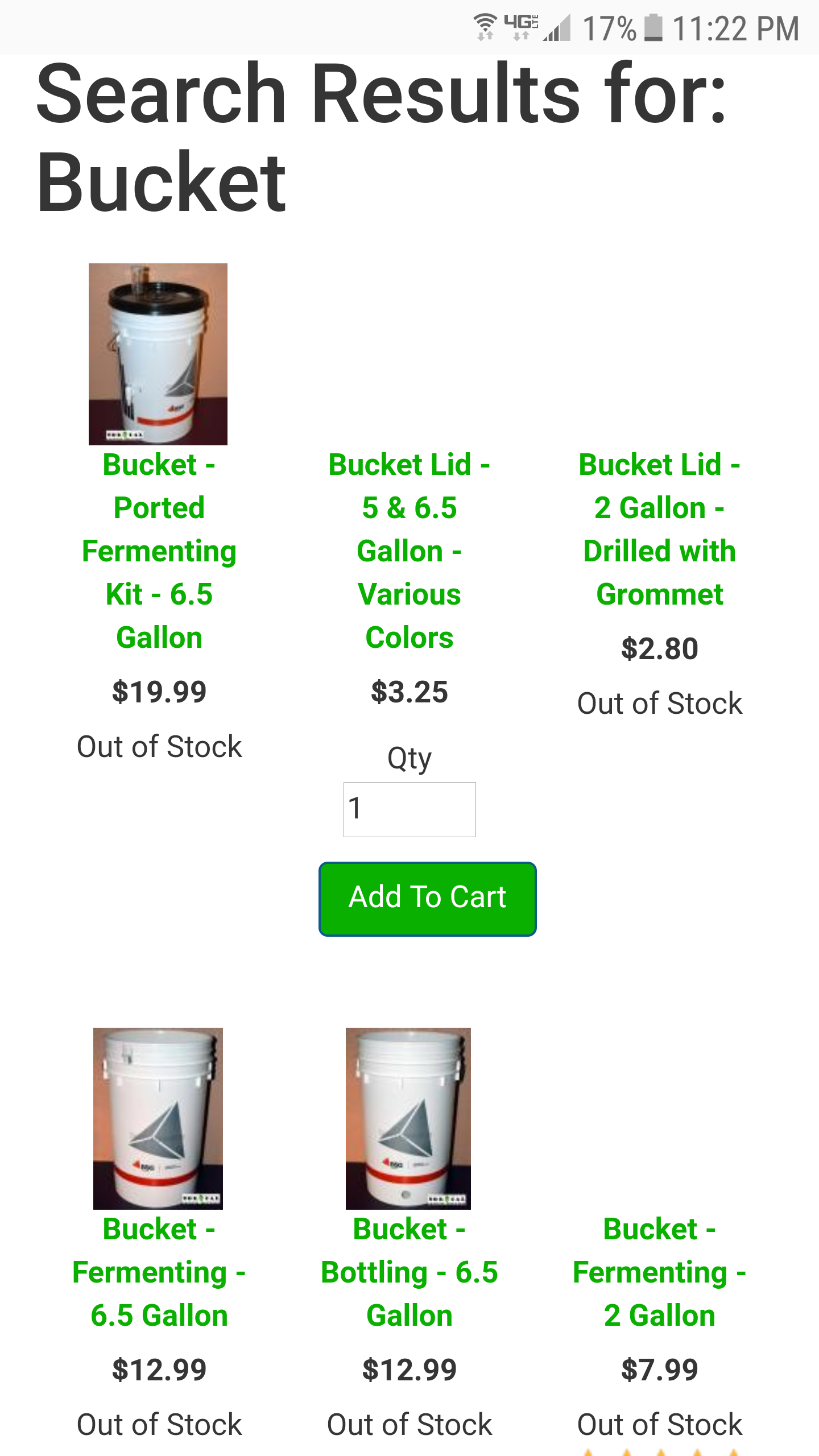

When cleaning my equipment at the end of the last batch I bottled, I noticed some blackish smudge on one of the washers on my bottling spigot. I believe my last two batches got infected during the bottling stage, and I strongly suspect this is the culprit. I plan to throw out my bottling bucket, bottling wand, spigot, siphon and tube and buy additional ones. I'm not sure if I should also throw out my plastic fermentation buckets.

At this point I have probably read every infection thread on the internet multiple times and cannot figure out solutions on why these problems keep reoccurring after discarding my equipment previously. My process, brewing, fermentation and storage locations have not changed since I was able to produce good beer.

Virtually all the threads on the internet say something along the lines of infections are caused by poor sanitation. Before I rack and bottle, everything that touches the beer gets soaked in PBW, rinsed, then soaked in Starsan. For the bottles themselves, they all get submerged in Starsan, drained, then filled with the beer.

At this point I have several questions:

- how airbourne are infectious bacteria? Ie, if I have an infected washer on a bottling spigot, would it be able to infect a bucket that is stored 10 feet away? Likewise, would an infected bucket infect another bucket that is a few feet away? Could an infection transfer onto the shelf that I'm storing things on?

- while I suspect infections are taking place during the bottling stage in these last few cases due to the beer tasting fine during the bottling process and taking on vinegary hues 3-4 weeks after bottling, I'm not 100% of this. What are the chances the beer has been infected in the primary and somehow laying dormant and not quite manifesting itself until weeks into the fermantation/aging process? In the case of that Belgian mentioned above that I know was infected in the primary, I could taste it right away. But some people say that infections don't always manifest themselves that quickly

- could the environment itself be infecting my equipment? I store all my brewing stuff in my attic on the same plastic shelving unit

- I boil and cool uncovered, both outside. I've heard some people suggest fruit flies are a source of infection, but I have never seen them, and I try to do most of my brewing in the winter, as I like to seasonally brew as to avoid using things like swamp coolers. Should I be covering during the cooldown process?

- Likewise, my bottling bucket is uncovered while bottling. Should a lid go on top after everything gets transferred in the bottling bucket?

- When I make my priming solution, I boil roughly 100 g of sugar in storebought spring water in a covered pot for roughly 15 minutes. While I clean the pot beforehand, I've never sanitized it, as I always assumed that having something at a boil for 15 minutes would kill any bacteria in the sugar, and that the temperature would be enough to sterilize the pot and lid. Is this an incorrect assumption? Should I be sanitizing the pot as well before I boil the sugar?

- Likewise, I'm assuming that putting sugar syrup additions a few days into the primary is now a Bad Idea, and it should be put in the boil to avoid possible infections at this stage. Other people seem to not have problems, but I assume the less infection points the better?

Any input would be appreciated. It sucks to have to punishment drink 50 sour beers when they should be delicious porters.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)