I agree with others that this is a whole process issue and not a simple tubing issue. I would go back and look at everything in the process. I would consider pressure fermentation in a sealed fermenter, purging the Star San filled kegs with fermentation CO2, then pressure transfers and storage in a refrigerator with just an occasional hookup of CO2 to maintain carbonation. This is about the best anyone could do for longer storage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oxidation question

- Thread starter walker111

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,965

- Reaction score

- 6,216

I brew double batches and keg . When I put a keg in keezer all is good and great beer flows. It seems the second keg that sits on a second co2 system in spare bedroom is becoming oxidized. It has happened a few times and always the second keg. These kegs can sit for some time , even a few months, but under pressure in a keg. I am miffed on this one. O2 getting in somewhere I assume.

Unless you have gone to considerable lengths to exclude it, the oxygen is already in your kegs. The difference is temperature. Staling, like most chemical reactions happens faster at higher temps. To estimate the difference, you can apply a rule of thumb (Arrhenius Law) that states that reactions happen 2-3 times faster for each 10C increase in temperature. Assuming 3x for each increase of 10C, a 10C increase would reduce your shelf life by 67%. A 20C increase would decrease your shelf life by 89% (i.e. the beer would stay "fresh" only 11% as long).

I’d let the second keg naturally carbonate with a 4-4.3 ounce charge of priming corn sugar. That will consume any stray O2 in the keg.

That would certainly take care of some of the oxygen. But as many IPA bottlers have discovered in a quite dramatic way, not all of it, unless measures are taken to minimize the starting O2. Fortunately (for keggers), that's easier to do in a keg than a bottle.

Large commercial breweries target dissolved O2 limits in low parts per billion at packaging, even for bottle conditioned beers. A couple of pro anecdotal tidbits:

John Mallet (Bells) said that the yeast will use about a third of the headspace O2. (Bells also CO2 purges and caps on foam, so one would have to assume John is talking about a much smaller amount of starting O2 than a homebrewer would typically get in the headspace.)

Garrett Oliver (Brooklyn) said "Yeast can remove small amounts of dissolved oxygen from beer, but very little from the bottle headspace air, which means these benefits will only attain to breweries using sophisticated brewing methods and very good packaging equipment."

That method, leaves the keg 1/3 filled with Starsan, and 2/3 filled with air, 21% of that being Oxygen. That translates to 14% (a volume of 3 quarts) is that keg is pure oxygen (!).

One of the better methods of 100% pre-purging that keg, is to fill it all to the way to the brim,* set the lid, and purge all the Starsan (or water) out, you'll get a keg that's 100% filled with CO2.

The essence is, the lid remains on the keg until the next cleaning. You'd fill the keg through the liquid out post with a QD attached to your transfer hose.

* Filling to the brim includes a few small details to also remove the small amount of air left under the lid and gas dome.

Then, a closed transfer from fermenter into the 100% pre-purged keg will prevent your beer being exposed to any, or as little as possible air (O2 being the bandit to avoid).

If you have a leak tight fermenter, there is no need to liquid purge the kegs. Just feed all the fermentation CO2 thru the (initially air filled) keg to be purged, with an airlock or spunding valve on the gas post of the keg. This will get the residual O2 in the keg below 5 ppb (parts per billion.)I agree with others that this is a whole process issue and not a simple tubing issue. I would go back and look at everything in the process. I would consider pressure fermentation in a sealed fermenter, purging the Star San filled kegs with fermentation CO2, then pressure transfers and storage in a refrigerator with just an occasional hookup of CO2 to maintain carbonation. This is about the best anyone could do for longer storage.

Brew on

walker111

Well-Known Member

Wow! I did not check in for a day and lots of response.

Double batch does mean 10 g for me and I am going to stick to that as like many of you sometimes finding the time to brew is a concern. I had a stockpile in my system and hence why there was so much beer around.......... usually not a big problem!!!!

I see that I have too much o2 in the empty keg getting the transferred beer. I clean good and when I purge out the starsan I only keep 1/2 to 1/3 in there as I thought I would be wasting so much co2.

This is same method for the first keg in the double batch but seems the second one sitting around develops the issue.

I also don't have enough space to keep the kegs colder other than the 4 tap keezer I built.

I hear people say to purge /burp the keg 15 times after it is kegged to rid 02. I probably only do 5 or so.

I can fix easy with the input given here. I have a few empty kegs right now and will re clean a few and fill with starsan and and try a natural purge coming of a fermenting beer to purge the starsan out of the available keg and use that keg when I package the beer ....

Could also try priming a keg with dextrose and let it condition like some have pointed out.

Thanks to you all I have some options and also know there is no need to keep the gas for so long on those kegs sitting.

Much appreciated.

Double batch does mean 10 g for me and I am going to stick to that as like many of you sometimes finding the time to brew is a concern. I had a stockpile in my system and hence why there was so much beer around.......... usually not a big problem!!!!

I see that I have too much o2 in the empty keg getting the transferred beer. I clean good and when I purge out the starsan I only keep 1/2 to 1/3 in there as I thought I would be wasting so much co2.

This is same method for the first keg in the double batch but seems the second one sitting around develops the issue.

I also don't have enough space to keep the kegs colder other than the 4 tap keezer I built.

I hear people say to purge /burp the keg 15 times after it is kegged to rid 02. I probably only do 5 or so.

I can fix easy with the input given here. I have a few empty kegs right now and will re clean a few and fill with starsan and and try a natural purge coming of a fermenting beer to purge the starsan out of the available keg and use that keg when I package the beer ....

Could also try priming a keg with dextrose and let it condition like some have pointed out.

Thanks to you all I have some options and also know there is no need to keep the gas for so long on those kegs sitting.

Much appreciated.

Last edited:

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

If you have a leak tight fermenter, there is no need to liquid purge the kegs. Just feed all the fermentation CO2 thru the (initially air filled) keg to be purged, with an airlock or spunding valve on the gas post of the keg. This will get the residual O2 in the keg below 5 ppb (parts per billion.)

We need a 'double like' button on this forum for posts such as this where one just isn't nearly good enough.

Glad this thread is helping. I just wanted to clarify a few things:I hear people say to purge /burp the keg 15 times after it is kegged to rid 02. I probably only do 5 or so.

I can fix easy with the input given here. I have a few empty kegs right now and will re clean a few and fill with starsan and and try a natural purge coming of a fermenting beer to purge the starsan out of the available keg and use that keg when I package the beer ....

1) I would leave the burp approach in the dust. There are better ways!

2) When you fill with Starsan or other sanitizer you need to push it out under pressure. (bottled CO2) Using fermentation gas will not work and is a different approach. See #3

3) Daisy chaining empty kegs to your fermenation gas output uses empty kegs. Many people use two kegs, one hooked up to the fermentation blowoff and the 2nd hooked up to the 1st keg. The airlock goes on the last keg and the 1st keg is the one used for adding your beer to. But there are many permutations. In the end, it is pure CO2 that is free if your fermentation chamber allows for it.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

If you are "burping" the keg a few times after filling it, the O2 in the keg headspace is minimal. Like a fraction of a percent. I would store the keg cold.

free air is only 21% oxygen. Before you pressurize the keg it's at 14.7 PSI sea level (0) gauge PSI). When you blast the keg with CO2 to say maybe 60 PSI and then bleed the PRV, you have just expelled 80% of that air and only 21% of that air it's O2. Leaving about 4% O2. Burp it again and another 80% of the oxygen is expelled down to under 1% in the head space. Only takes a few times to get to 0.0?% oxygen left.

A little priming sugar will clean up any oxygen that remains. After a few days for the yeast to do it's thing, cold crash and store cold. I think that might fix your oxidation issues.

free air is only 21% oxygen. Before you pressurize the keg it's at 14.7 PSI sea level (0) gauge PSI). When you blast the keg with CO2 to say maybe 60 PSI and then bleed the PRV, you have just expelled 80% of that air and only 21% of that air it's O2. Leaving about 4% O2. Burp it again and another 80% of the oxygen is expelled down to under 1% in the head space. Only takes a few times to get to 0.0?% oxygen left.

A little priming sugar will clean up any oxygen that remains. After a few days for the yeast to do it's thing, cold crash and store cold. I think that might fix your oxidation issues.

Last edited:

Panderson1

Well-Known Member

- Joined

- Dec 23, 2020

- Messages

- 371

- Reaction score

- 156

Purge (burp) more. I always felt 3-5 times is not enough. I burp it 15-20 times lol. It's worth the $ (gas) to me.

1) Yes, the burping is only needed if you open the keg to the atmosphere after a good purge - to add dry hops for example, or a non-closed transfer to the keg.Glad this thread is helping. I just wanted to clarify a few things:

1) I would leave the burp approach in the dust. There are better ways!

2) When you fill with Starsan or other sanitizer you need to push it out under pressure. (bottled CO2) Using fermentation gas will not work and is a different approach. See #3

3) Daisy chaining empty kegs to your fermenation gas output uses empty kegs. Many people use two kegs, one hooked up to the fermentation blowoff and the 2nd hooked up to the 1st keg. The airlock goes on the last keg and the 1st keg is the one used for adding your beer to. But there are many permutations. In the end, it is pure CO2 that is free if your fermentation chamber allows for it.

2) It only takes ~2 psi to push sanitizer out of a keg (but add another 0.5 psi for each additional foot the outlet is above the keg.) So, if your fermenter can be even slightly pressurized, you can use fermentation CO2 to push sanitizer out. BUT, if you hook the keg to the fermenter at the beginning of the fermentation, there is no need to have it filled with liquid.

Brew on

Last edited:

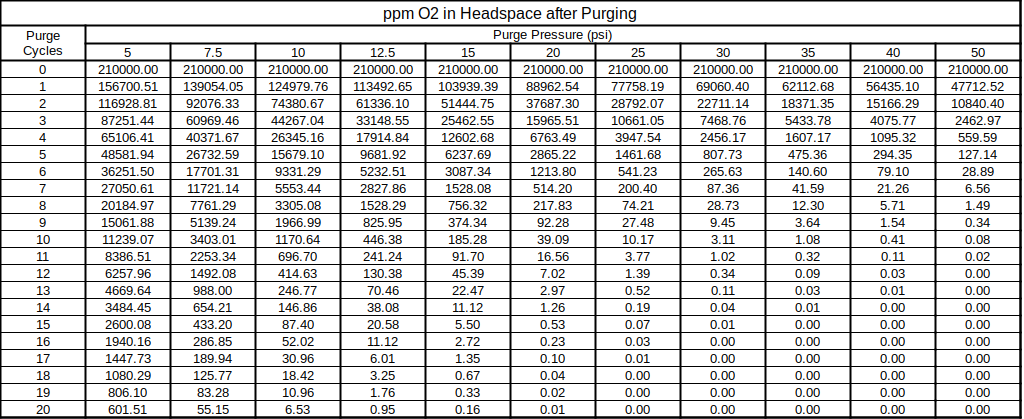

Yes, the O2 concentration drops a lot with each purge cycle. The problem is that the O2 target is about 100 ppb (0.1 ppm), and it takes a lot of purges to get there (higher pressure requires fewer purges.) Also, the O2 never gets to 0 theoretically, and practically you can't go lower than the O2 content of the CO2 you are using to purge. I published the following chart and table about residual O2 content vs. purge cycles a long time ago, and it's been reposted many times on HBT.If you are "burping" the keg a few times after filling it, the O2 in the keg headspace is minimal. Like a fraction of a percent. I would store the keg cold.

free air is only 21% oxygen. Before you pressurize the keg it's at 14.7 PSI sea level () gauge PSI). When you blast the keg with CO2 to say maybe 60 PSI and then bleed the PRV, you have just expelled 80% of that air and 80% of it's O2. Leaving about 4% O2. Burp it again and another 80% of the oxygen is expelled down to under 1% in the head space. Only takes a few times to get to 0.0?% oxygen left.

A little priming sugar will clean up any oxygen that remains. After a few days for the yeast to do it's thing, cold crash and store cold. I think that might fix your oxidation issues.

Brew on

yep...CO2 is 2 parts oxygen anyway...

just toss a little priming sugar into the keg, purge a few times, let the yeast tackle any errant O2 and call it good.

I seriously doubt oxygen can ever be eliminated...only minimized...

just toss a little priming sugar into the keg, purge a few times, let the yeast tackle any errant O2 and call it good.

I seriously doubt oxygen can ever be eliminated...only minimized...

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,965

- Reaction score

- 6,216

yep...CO2 is 2 parts oxygen anyway...

The "O2 content of the CO2" @doug293cz referred to is not the "O2" part of the CO2 molecules. He's talking about the free oxygen molecules (O2) that exist as a contaminant (along with other gas contaminants, BTW) in CO2 supplies. It would take a lot of energy to split O2 off from CO2, thus making it available to oxidate the beer. This doesn't happen. If it were easy, we could solve global warming just like that.

Yes, correct. It is tough to write posts so well that all scenarios are covered.1) Yes, the burping is only needed if you open the keg to the atmosphere after a good purge - to add dry hops for example, or a non-closed transfer to the keg.

2) It only takes ~2 psi to push sanitizer out of a keg (but add another 0.5 psi for each additional foot the outlet is above the keg.) So, if your fermenter can be even slightly pressurized, you can use fermentation CO2 to push sanitizer out. BUT, if you hook the keg to the fermenter at the beginning of the fermentation, there is no need to have it filled with liquid.

Brew on

1) What I meant was burping is not the best way to approach getting O2 out of kegs and is kind of "old" homebrew thinking imho.

2) What I meant to stress was that "normal" fermentation gas output is not enough to push sanitizer out of a keg. So one can not just hook your blowoff to a keg and push the sanitizer out. Which to your point, you would not need liquid in there in the first place if you hooked your blowoff tube to the keg!

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,965

- Reaction score

- 6,216

2) What I meant to stress was that "normal" fermentation gas output is not enough to push sanitizer out of a keg. So one can not just hook your blowoff to a keg and push the sanitizer out. Which to your point, you would not need liquid in there in the first place if you hooked your blowoff tube to the keg!

Normal fermentation gas output can push the sanitizer out of a keg, assuming the fermenter isn't leaky. But as noted, you don't need the sanitizer (except to sanitize).

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

granted, I have not tied a shot of it...

Go ahead.. I dare ya!

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,965

- Reaction score

- 6,216

Go ahead.. I dare ya!

I betcha it's "tart."

I have never used my fermenter to push sanitizer out of a keg but I do use a CO2 tank. Seems like it would be tough to get the last bits out but others are doing it. Something I would like to look into with my setup.Normal fermentation gas output can push the sanitizer out of a keg, assuming the fermenter isn't leaky. But as noted, you don't need the sanitizer (except to sanitize).

Last edited:

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

I betcha it's "tart."

Yea for sure phosphoric is going to be tart but I'll bet the dodecylbenzenesulfonic acid ester component is delicious.

I am amazed at that word. Had to have been discovered by a German at least...

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

I am amazed at that word. Had to have been discovered by a German at least...

Yes, for degreasing the engine in his Benz.

If your keg is filled as much as possible with StarSans, then it's not really that much gas.Purge (burp) more. I always felt 3-5 times is not enough. I burp it 15-20 times lol. It's worth the $ (gas) to me.

If your keg is really as full as possible with liquid, you can't burp it.If your keg is filled as much as possible with StarSans, then it's not really that much gas.

Brew on

Similar threads

- Replies

- 18

- Views

- 1K

- Replies

- 66

- Views

- 3K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)