Ok so ive read a few posts on this and I thought i understood how top do this.. i have a frigidare 5000btu unit listed here:

https://www.amazon.com/dp/B00W2KG92Y/ref=cm_sw_r_cp_awdb_t1_O80lDbFBZKGTS

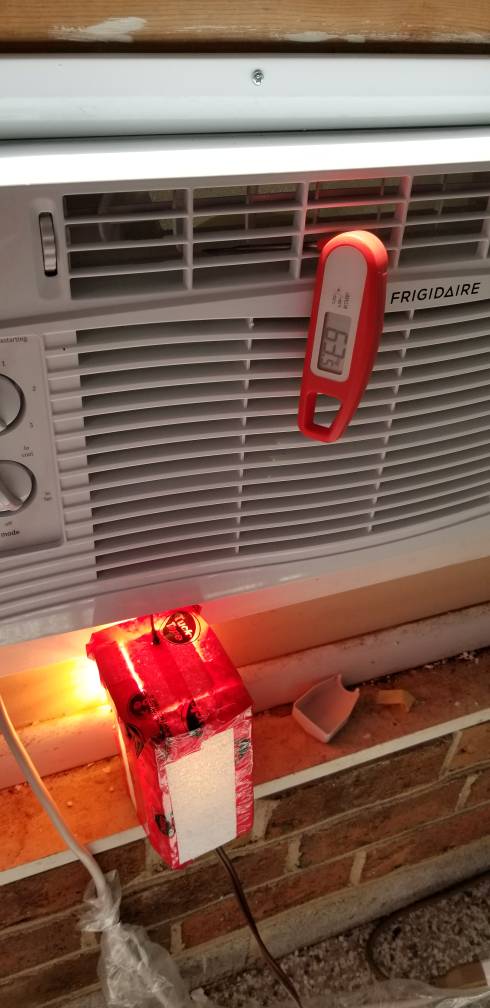

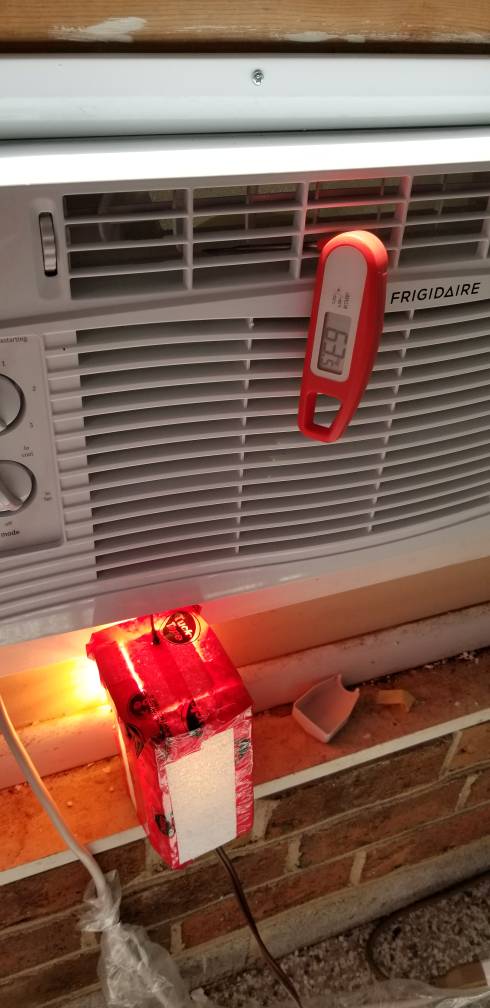

I took off the cover and moved the copper temperature sensor out. I bought a night light (replaced the tiny bulb with a larger one that was hot the minute i plugged it in) put an incandescent bulb in, created a "hot box" for the sensor And the light, and cranked it up. I can't seem to get the temp below 62/63. What am i doing wrong?

https://www.amazon.com/dp/B00W2KG92Y/ref=cm_sw_r_cp_awdb_t1_O80lDbFBZKGTS

I took off the cover and moved the copper temperature sensor out. I bought a night light (replaced the tiny bulb with a larger one that was hot the minute i plugged it in) put an incandescent bulb in, created a "hot box" for the sensor And the light, and cranked it up. I can't seem to get the temp below 62/63. What am i doing wrong?