ReuFroman

Well-Known Member

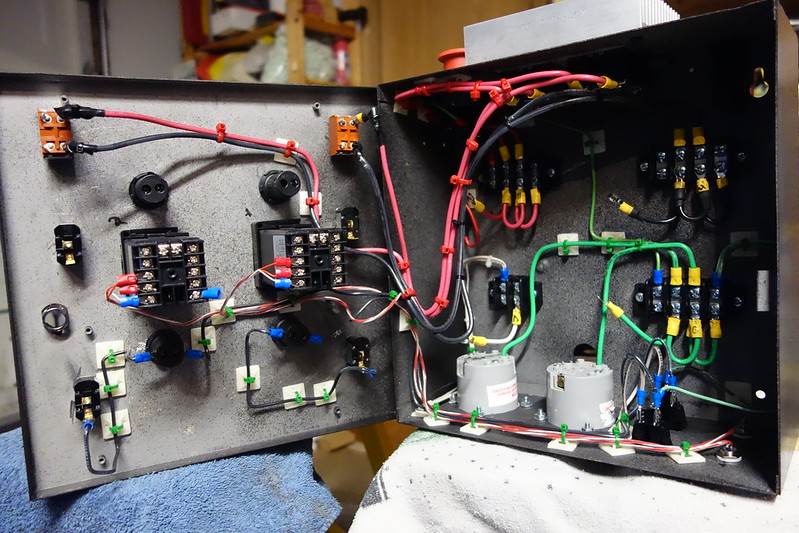

kal said:You probably mean my post a few posts above: https://www.homebrewtalk.com/f170/open-your-panel-show-me-whats-inside-438542/index3.html#post5611443 Why? Because it looks cleaner and may make part replacement simpler. Worth it? That's up to you. Kal

Of course when I'm on the iPad having to rely on crappy slow 3G internet. Sorry I couldn't see images so well.

I think it looks so clean plus you can make some cool colors for the mounting plate. Looks like I'm going to the store for some color choices and grommets.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)