DangersBrew

Well-Known Member

- Joined

- Jun 4, 2020

- Messages

- 52

- Reaction score

- 8

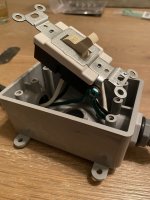

I installed a Leviton 15/20 amp on/off switch into a plastic gang box hard wired into my hot rod cable. It’s a 1650 watt element and I wanted to safely turn the element off and on without unplugging from an outlet. My question is does the ground wires need to be connected into the on/off switch green ground nut or is it fine to not ground the wires to the electric switch since it’s in a plastic box. Can I just wire the ground wires together with a wire nut instead. As a precaution I ended up wiring the 2 green ground wires together with one wire nut and having an extra a long pigtail sticking out of the green twist then attached to the ground screw on the ground switch. I didn’t know if this was necessary or just having the ground wires that are wire twisted together with a twist wire connector is suffice. I attached a pic of the finished product.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)