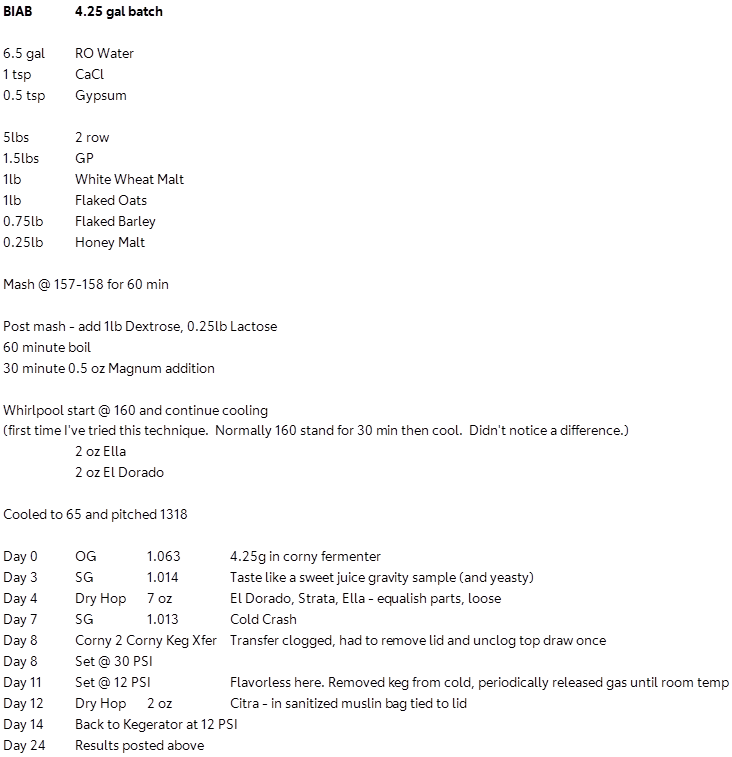

Possibly. But does it go from flavorless to juice bomb? Something is up. One thing I haven’t explored is PH. I start from RO and add my CaCL and Gypsum 2:1 ratio, but aside from that it’s your standard grist with 12-14oz hops on average. Color and mouthfeel are both acceptable, but can’t get that punch!

I usually try mine after 1 week of carbing, and while they aren't totally flavorless, they aren't very tasty yet. After 2 weeks it's better, and after 5-6 weeks I am finally getting really nice flavor and aroma. My previous batch, with 18 ounces of hops for a 6-gallon batch, was my best yet -- it was getting closer to my goal of tasting like King Sue from Toppling Goliath.

My latest 6-gallon batch

only has 14 ounces of hops, because everyone keeps telling me that less is more... The jury is still out, though it does seem to be on a good path in terms of flavor (I used Galaxy, Citra, Mosaic, and Simcoe) -- I'll know for sure in another few weeks!

I am still learning about water, and I tried the 2:1 Cl to So ratio for my latest batch (it ended up 147 cl to 87 so) that is carbonating. I can say that so far I don't notice any change in mouthfeel (or softness) from the water, and I did detect a slight chemical taste (which now seems to be fading). For my next batch, I am going to ditch the high Cl and reverse it, going for a West Coast IPA water profile to make the hops pop, so 2:1 So to Cl. Maybe the next one will be balanced between the two...

I do try for 5.4 mash ph, using the water calculator for the chemical additions, but I don't measure actual (I didn't get the ph meter I had on my X-mas wish list).

But I feel you on the punch! Maybe that's what we are ALL chasing?! I do believe it comes from heavy whirlpool additions and then late dry hopping. Not sure about the biotrans addition, but I figure two dry hop additions can't hurt, so I do it.

Now, as to the amount of hops, the types, and the ratios for hot and cold side additions... well, that's up for so much debate and experimentation! Right now I split 50-50 for hot and cold side hops.

The processes I am most interested in now are the ratios and amount of hops people are using for hot and cold side. I'd love to hear from people who do, say, 70% hot side and 30% dry hop, or the reverse!

I am also interested in the length and temps for hop stands. The latest Janish recipe seems to suggest that long hop stands are not necessary, and stands under 185 aren't necessary either. That is different from what I previously read and what a lot of people do... Ah, conflicting advice -- that's what makes this fun, right?

UPDATE: After 3 weeks in the bottle I am now noticing the softness from the 2:1 Cl to So adjustment. I wasn't expecting it, but I tried a bottle last night and was really struck by how soft it felt. Now, I am not personally all that interested in that aspect of this style, so I still plan to reverse the ratio for my next batch, but I do think it's cool how much the water profile can affect the beer. As for the taste, the chemical taste has receded, and the hop flavor is good, but at this point I think all the 14 ounces did was reduce the flavor -- so I think I'll go back to 18 ounces next time, and maybe even experiment with some of it being cryo.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)