MSK_Chess

enthusiastic learner

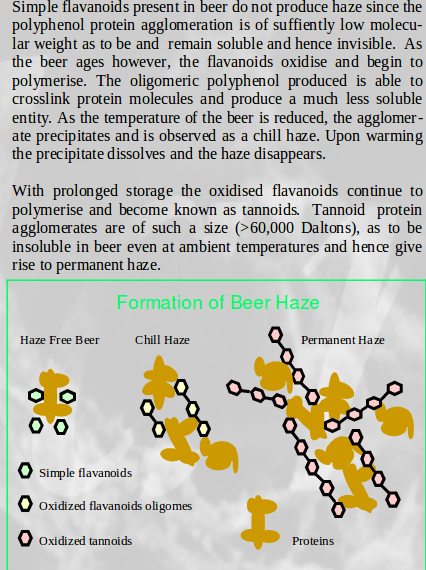

I have been trying some experiments and I am really happy to state that as the LODO guys stated you DO NOT need post fermentation finings. Lagering can and does clear beer amazingly so. Here is a British Pale Ale that I brewed using LODO techniques. It utilised a small amount of wheat and was also dry hopped in the keg with about 30 grams (1 ounce) of Styrian Goldings (I have my own technique for this). It was partially fermented and transferred to keg to spund. Spunding took place when about 50% attenuation had been reached (this is more than is recommended but I am using British yeast which drops much faster than lager yeast and I don't want to risk under attenuation as the style should be dry) It was allowed to ferment out at room temperature with about 30psi setting on the spunding valve. Afterwards temperature was gradually reduced and It was lagered at -1C for two weeks and served at that temperature. I did not use any post fermentation finings like gelatin or polyclar730 and as you can see it is crystal clear and has NO chill haze.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)