twst1up

Well-Known Member

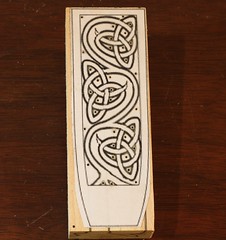

beautiful work....bravo

...I did a lot of carving in my youth...mostly caricatures and things...sort of like these examples...

http://www.pioneermtwoodworking.com/catalog7.html

...not carved in a long time...from this thread it sounds like you are just starting...keep up the good work...looks great!

Of note, I have a lot of different carving tools...oddly, this (with the curved blade) was always my favorite..

http://www.xacto.com/Product/X3261

Cheers!

DAMN! I dabble in woodwork, but you are an artist. The second one is by far nicer. Nice choice of wood. Are these designs just in your head or are you going off a drawing/template?

Too bad tiger maple is so expensive...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Next steps are to choose a wood,

Something dense and hard like ipe perhaps?

MadDwarf,

I love the handle, though anything like that is beyond my capability. But question... what kind of wood and finish is the collar on your keezer? TIA!

---VikeMan

These are quite impressive...I hate to be "that guy" and I am in no way trying to take away from your skill but my only complaint would be they are too short. I like my handles long though.