Putting a pump in the feed line after the pre-filters sends the feed to the membranes at high pressure thus increasing the recovery (permeate flow relative to concentrate). Systems sometimes have additional pumps. For example the permeate in my system is accumulated in an atmospheric tank and a second pump is used to transfer water from the atmospheric tank to a pressure tank. The pressure tank is plumbed to the brewery and lab.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New RO Membrane Troubleshooting

- Thread starter schematix

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Membranes used in small home-based RO machines have a much lower feedwater pressure capability than the industrial units I design around. In addition, these home-based membrane manufacturers only recommend booster pumps when the feedwater pressure is below their specifications. Be sure to consult the membrane manufacturer's pressure recommendation and your water supply pressure before throwing a booster pump on your system. The membranes can be ruptured by excessive pressure drop across the membrane.

If you are using a cascading set of membranes in series, then it is possible to use a booster pump on the first stage when the subsequent stages impose adequate backpressure to avoid excessive pressure drop across the membranes.

If you are using a cascading set of membranes in series, then it is possible to use a booster pump on the first stage when the subsequent stages impose adequate backpressure to avoid excessive pressure drop across the membranes.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Martin, the Filmtec membranes can deal with 150PSI. I had the same concerns as you so I browsed the Dow website for info.

It's been my experience that the more pressure you feed the membrane (Within reason, and under the maximum) the more permeate is generated and the higher the rejection rate.

When I say I have two membranes in series, I don't mean I have permeate running from one membrane into a second; I have the feed water running into the first membrane, and the concentrate from the first membrane runs into the feed water fitting on the second membrane, then to the flow restrictor and out. The permeate lines are tee'd together and run to the collection point. In essence, I'm turning two 75GPD membranes into a longer 150GPD. With the added pressure I'm actually generating in the neighborhood of 200 GPD at 4-5 TDS.

It's been my experience that the more pressure you feed the membrane (Within reason, and under the maximum) the more permeate is generated and the higher the rejection rate.

When I say I have two membranes in series, I don't mean I have permeate running from one membrane into a second; I have the feed water running into the first membrane, and the concentrate from the first membrane runs into the feed water fitting on the second membrane, then to the flow restrictor and out. The permeate lines are tee'd together and run to the collection point. In essence, I'm turning two 75GPD membranes into a longer 150GPD. With the added pressure I'm actually generating in the neighborhood of 200 GPD at 4-5 TDS.

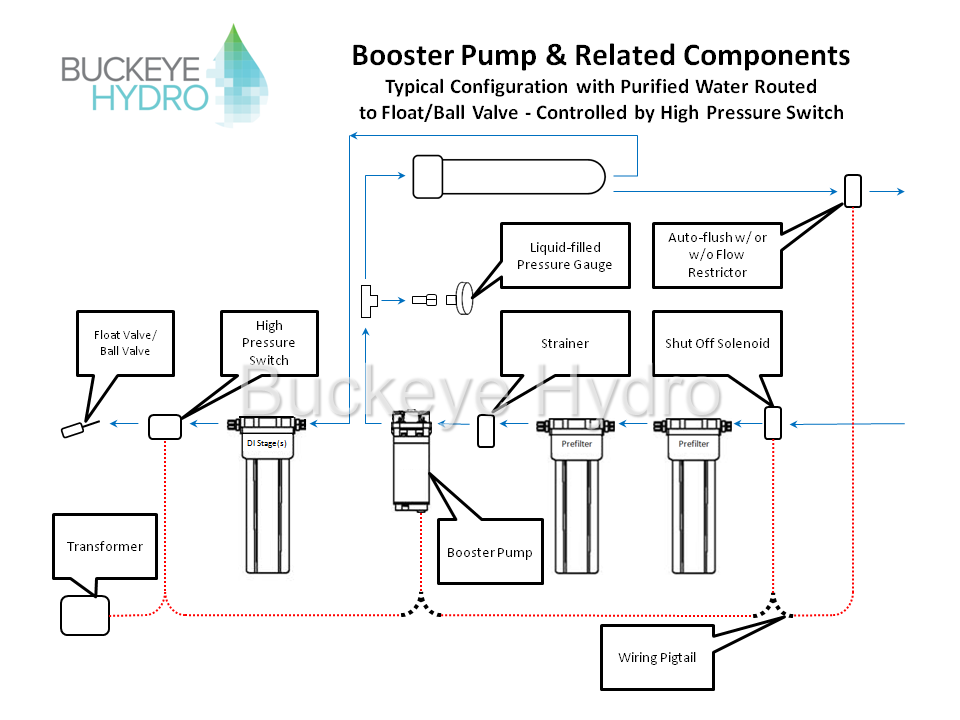

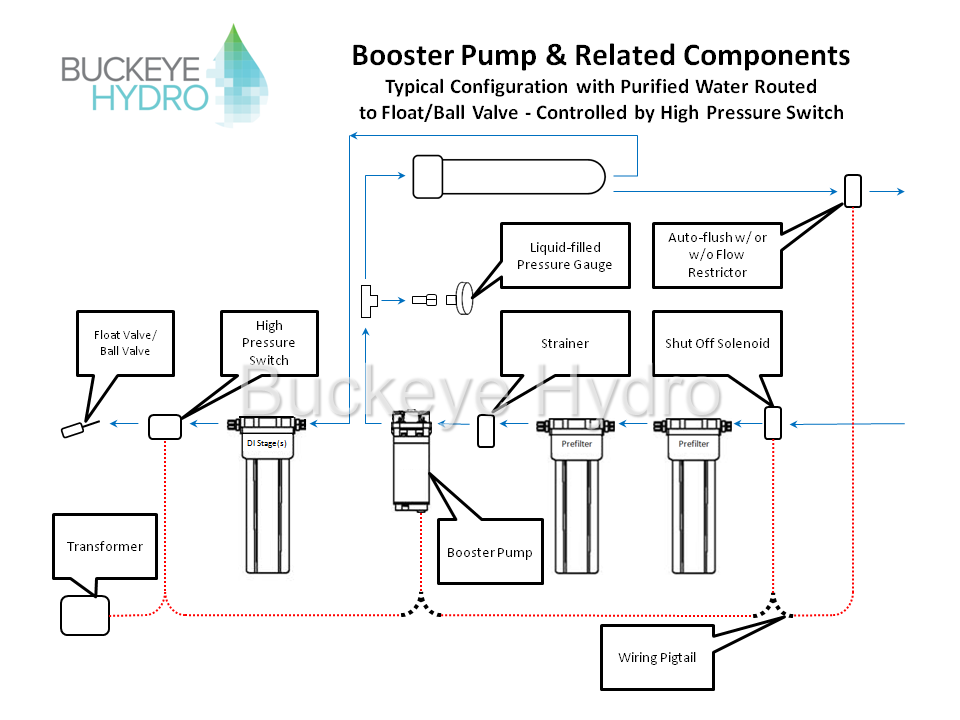

From our booster pump instructions. Your system may not have the DI stage, or all the other pump accessories shown.

Russ

Russ

From our booster pump instructions. Your system may not have the DI stage, or all the other pump accessories shown.

Russ

This really helps. Thanks, Russ. The pressure switch is the piece I was wondering about.

For a closer look, http://www.buckeyehydro.com/high-pressure-switch/

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

The weakest link in residential systems in terms of ability to withstand elevated pressures is typically the clear housings. This is the reason we recommend putting the pump AFTER all the prefilters.

Similar threads

- Replies

- 63

- Views

- 4K

Latest posts

-

The Dysfunctional-Palooza Obnoxious Masshole BS Thread

- Latest: TheDudeLebowski

-

-

-

-

-

-

-

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)