BrewSpook

Well-Known Member

Hey guys - just wanted to run my system design by everyone and look for input.

I have been brewing on a 2 vessel No-Sparge (Continuous Sparge) system for almost 4 years now and I love it. I want to automate as much as possible so I can evetually brew from work using a web interface. I just built the first iteration of my stand this weekend and brewed on it - needs a few modifications, but worked pretty well.

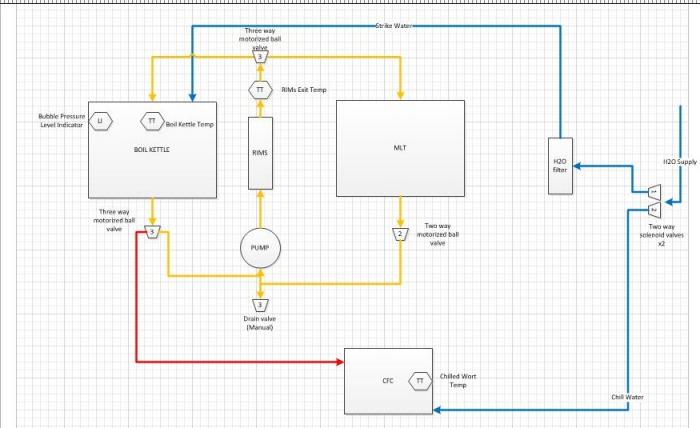

Here is the plumbing diagram I came up with for my rig - please let me know what you think and if you see anything I should be aware of.

This will all be controlled via an Arduino interface. 2 x 3way motorized ball valves, 1 x 2 way motorized ball valve, 2x solenoid valves for H2O supply lines, a single pump, the RIMs tube, and 3 K type thermocouples. I will also eventually add in an agitator to the MLT and electric element to the BK for ease of use and indoor brewing once I get water and power run to my shed.

I have been brewing on a 2 vessel No-Sparge (Continuous Sparge) system for almost 4 years now and I love it. I want to automate as much as possible so I can evetually brew from work using a web interface. I just built the first iteration of my stand this weekend and brewed on it - needs a few modifications, but worked pretty well.

Here is the plumbing diagram I came up with for my rig - please let me know what you think and if you see anything I should be aware of.

This will all be controlled via an Arduino interface. 2 x 3way motorized ball valves, 1 x 2 way motorized ball valve, 2x solenoid valves for H2O supply lines, a single pump, the RIMs tube, and 3 K type thermocouples. I will also eventually add in an agitator to the MLT and electric element to the BK for ease of use and indoor brewing once I get water and power run to my shed.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)