Well I've searched the forum and can't find an answer to the problem I'm having so here goes.

Equipment

I converted my single tier brew stand from

New set-up

Problem

Burner will not light and stay lit.

Description:

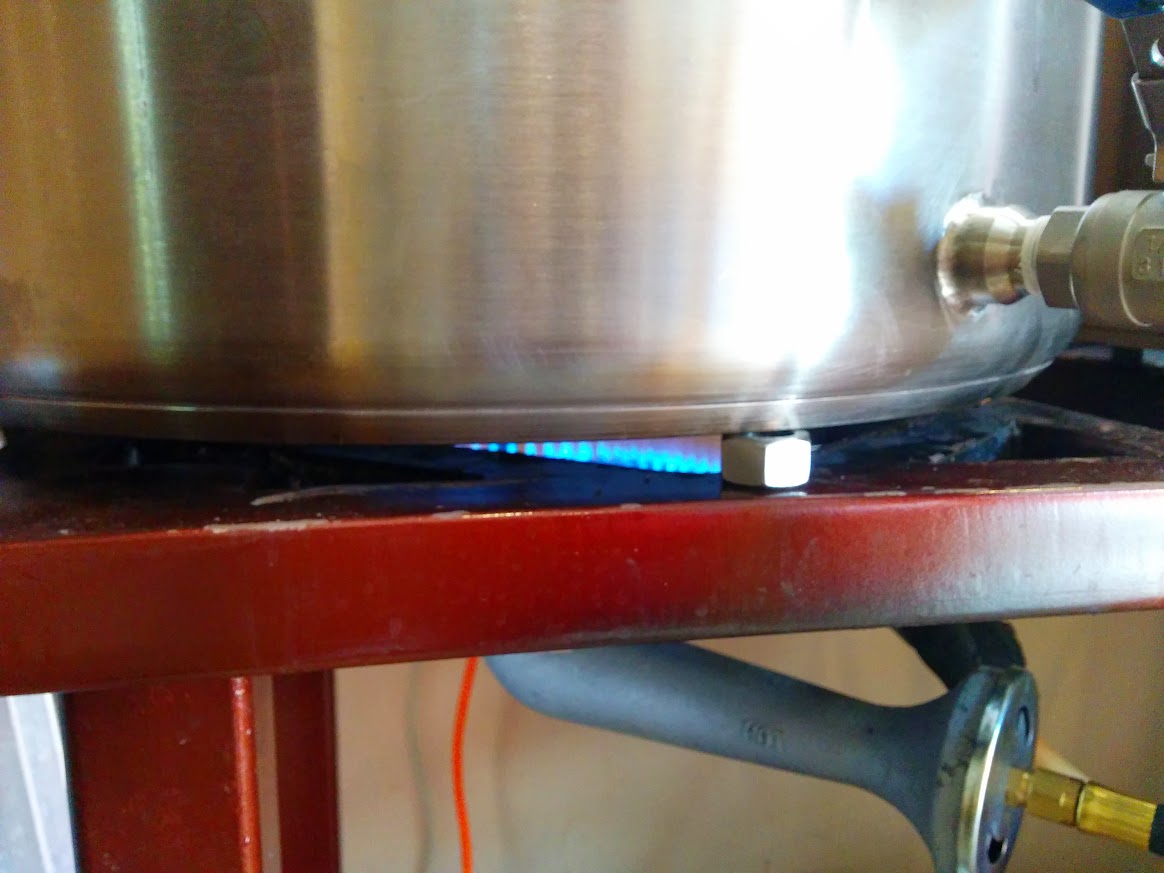

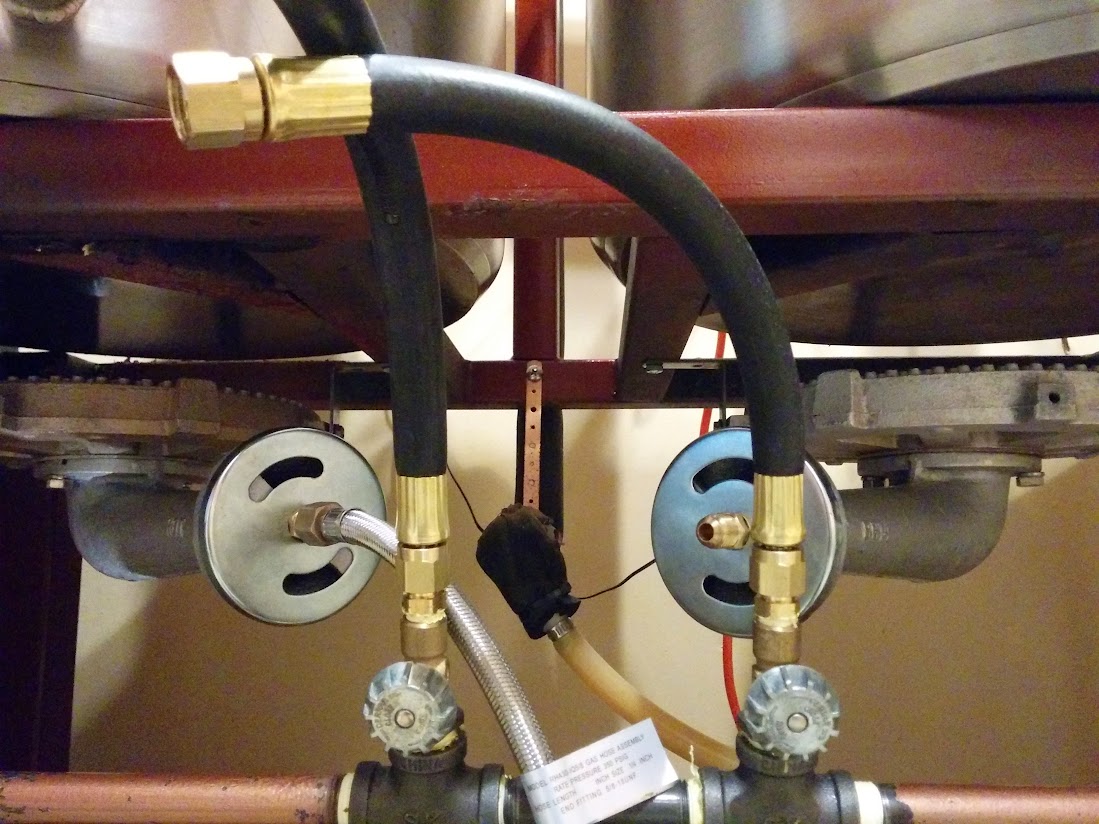

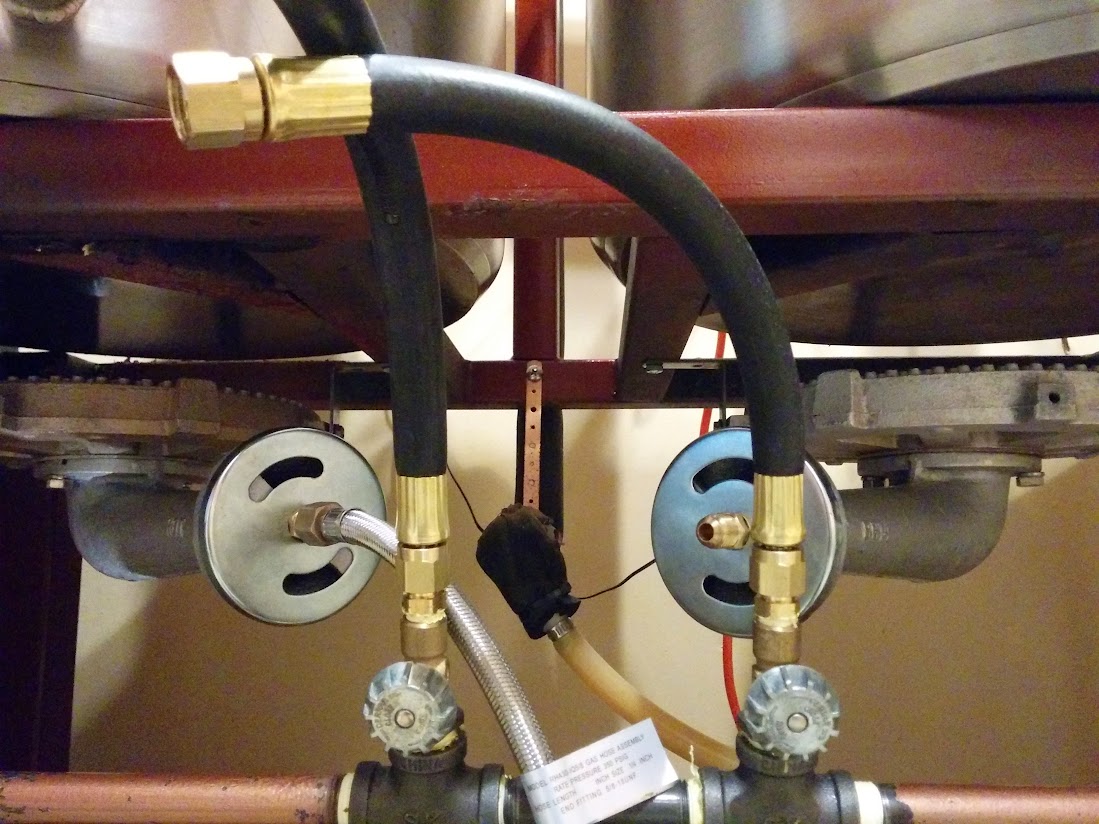

With no kettles on stand I can light the burners fine, no problem. Once I place the kettles on the stand the burners are almost impossible to lite and impossible for them to stay lit. When I place my long handle lighter at the edge of burner and turn on the gas I just get a BIG poof. When I am able to get a few holes lit the flame starts to spread across the burner and then poof. My first thought was a bad regulator so I hooked up the old BG-10 burner directly to the regulator and it worked fine. I was able to get the burner lit by connecting the regulator directly to the burner and using the regulator to control the flame, bypassing the needle valve. At first my burners were 1-1\4 inches from bottom of kettle. I have now lowered them to 2-5\8 inches. I have attached some images and a short crappy video of the burners in action.

Equipment

I converted my single tier brew stand from

- 2 BG-10 Burners 1 each on HLT and Boil kettle

- 0-10 psi regulator on a 20.lb propane cylinder

- needle valves at each burner to provide adjustment

- 15 gal Boil kettle flat bottom

- HLT converted Keg.

New set-up

- 3 BG-14 Burners 1 each on HLT, Mash Tun, Boil Kettle

- 0-30 psi regulator on a 20 lb propane cylinder

- needle valves at each burner to provide adjustment

- All vessels are now 26 gallon w/ flat bottom

Problem

Burner will not light and stay lit.

Description:

With no kettles on stand I can light the burners fine, no problem. Once I place the kettles on the stand the burners are almost impossible to lite and impossible for them to stay lit. When I place my long handle lighter at the edge of burner and turn on the gas I just get a BIG poof. When I am able to get a few holes lit the flame starts to spread across the burner and then poof. My first thought was a bad regulator so I hooked up the old BG-10 burner directly to the regulator and it worked fine. I was able to get the burner lit by connecting the regulator directly to the burner and using the regulator to control the flame, bypassing the needle valve. At first my burners were 1-1\4 inches from bottom of kettle. I have now lowered them to 2-5\8 inches. I have attached some images and a short crappy video of the burners in action.

Last edited by a moderator: